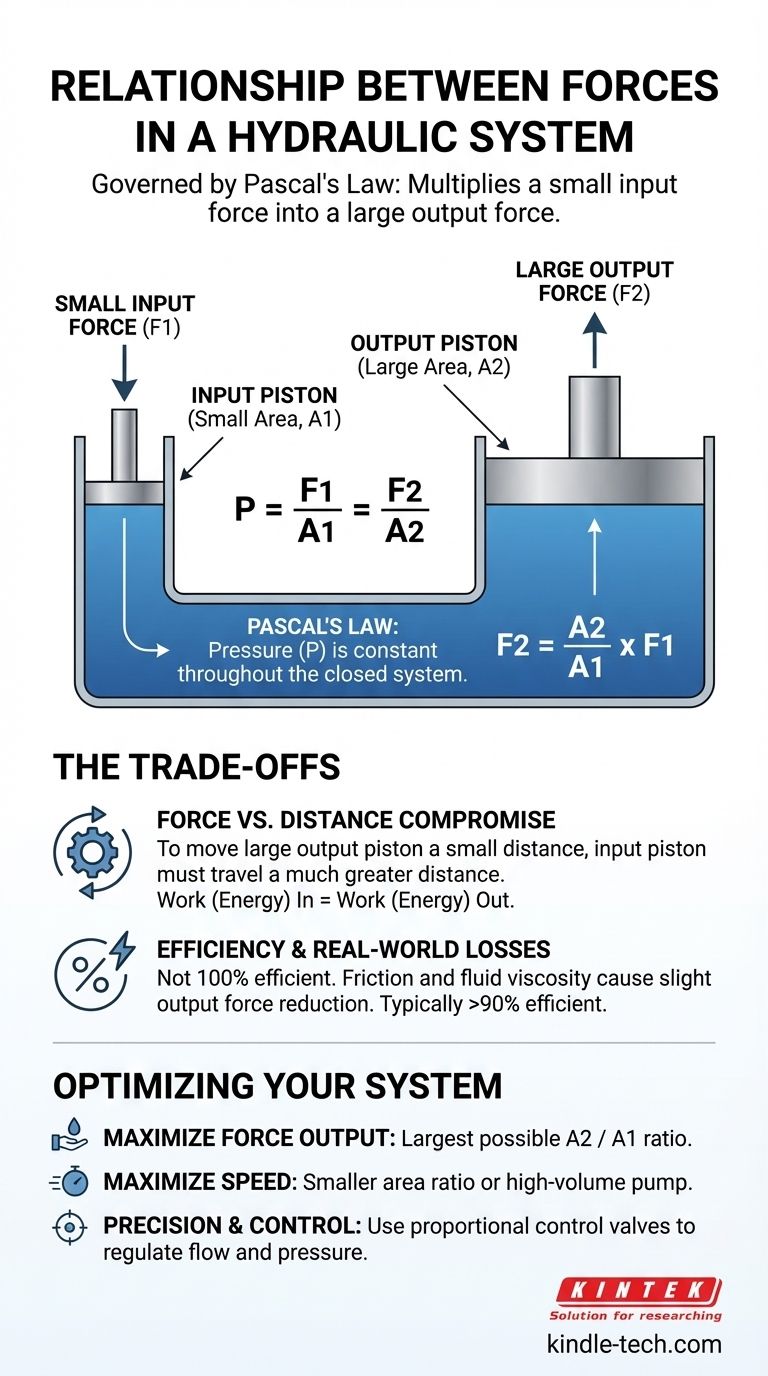

At its core, the relationship between forces in a hydraulic system is governed by Pascal's Law, which allows a small input force to be multiplied into a significantly larger output force. This principle of force multiplication is achieved by applying pressure to a confined, incompressible fluid, like oil.

The fundamental relationship is that pressure remains constant throughout a closed hydraulic system. By manipulating the surface area on which this pressure acts, you can directly trade a small force applied over a small area for a large force generated over a large area.

The Core Principle: Pascal's Law

The entire foundation of hydraulic power rests on a simple principle discovered in the 17th century. Understanding this is key to understanding how all hydraulic machinery, from a car's brakes to a 300-ton press, operates.

What is Pascal's Law?

Pascal's Law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally throughout the fluid. In simpler terms, if you push on the fluid in one spot, the pressure everywhere inside the container increases by the same amount.

The Role of Pressure

Pressure is defined as Force divided by Area (P = F/A). This simple formula is the key to unlocking force multiplication. By controlling the area, you can directly influence the force.

How Force is Multiplied

Imagine a sealed container with two pistons of different sizes: a small input piston (Area 1) and a large output piston (Area 2).

When you apply a small force (Force 1) to the small piston, you generate pressure (Pressure = Force 1 / Area 1).

Because this pressure is transmitted equally throughout the fluid, the same pressure pushes up on the large output piston. This creates a much larger output force (Force 2 = Pressure x Area 2).

Since the pressure is the same, we can say F1/A1 = F2/A2. This equation shows that the output force (F2) is directly proportional to the ratio of the areas. If the output piston has 10 times the area of the input piston, you get 10 times the force.

Understanding the Trade-offs

Force multiplication does not create energy from nothing. This powerful advantage comes with inherent compromises that are critical to understand in any practical application.

The Force vs. Distance Compromise

The most significant trade-off is between force and the distance the piston must travel. To move the large output piston a small distance, the small input piston must be pushed a much greater distance.

Work (Energy) is calculated as Force times Distance. The work done on the input side must equal the work done on the output side (ignoring friction). If you multiply the force by 10, you must also multiply the travel distance of the input piston by 10 to achieve the same output travel.

Efficiency and Real-World Losses

The formula F1/A1 = F2/A2 describes a perfect, frictionless system. In reality, you will always have efficiency losses.

Friction between the seals and cylinder walls, as well as the internal friction (viscosity) of the hydraulic fluid, will slightly reduce the actual output force. A well-designed system is typically over 90% efficient, but it is never a perfect 100%.

The Element of Control

Raw power is useless without the ability to manage it. Simply applying force to a piston gives you no precision over the speed or magnitude of that force.

This is where components like proportional control valves and proportional pump controls become essential. They don't generate the force, but they precisely regulate the fluid's flow rate and pressure, allowing an operator to finely control the speed and force of the hydraulic actuator for complex tasks.

Making the Right Choice for Your Goal

Understanding this force relationship allows you to evaluate system design based on your primary objective.

- If your primary focus is maximizing force output: The goal is to design a system with the largest possible ratio between the output area and the input area.

- If your primary focus is speed: You may need to accept a lower force multiplication factor (a smaller area ratio) or utilize a high-volume pump to move the required amount of fluid faster.

- If your primary focus is precision and control: The mechanical advantage is only half the equation; your system's effectiveness will depend on high-quality valves and controls to accurately modulate the hydraulic pressure and flow.

Grasping this balance between pressure, area, and displacement is the first step toward mastering the application of hydraulic power.

Summary Table:

| Concept | Key Formula | Practical Implication |

|---|---|---|

| Pascal's Law | Pressure is transmitted equally | Small input force creates large output force |

| Force Multiplication | F1/A1 = F2/A2 | Output force scales with area ratio |

| Trade-off | Work In = Work Out | Increased force requires increased input distance |

| Efficiency | Typically >90% | Real-world systems account for friction losses |

Ready to harness precise hydraulic power for your lab? At KINTEK, we specialize in high-performance lab equipment and consumables, ensuring your hydraulic systems operate with maximum efficiency and control. Whether you need reliable components or expert advice on force multiplication for your applications, our team is here to help. Contact us today to optimize your hydraulic solutions!

Visual Guide

Related Products

- Variable Speed Peristaltic Pump

- Cylindrical Press Mold with Scale for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Polygon Press Mold for Lab

- Assemble Square Lab Press Mold for Laboratory Applications

People Also Ask

- How do you inspect a vacuum pump? A Step-by-Step Guide to Ensure Peak Performance

- What is the role of the constant flow and constant pressure pump in core flooding? Master Deep Granite Stimulation

- What are the common uses of vacuum pumps in laboratories? Essential for Filtration, Evaporation & Analysis

- What is the primary function of a vacuum pump? Remove Gas Molecules to Create a Controlled Vacuum

- Why is a water circulating vacuum pump suitable for handling flammable or explosive gases? Inherent Safety Through Isothermal Compression