At its core, a water circulating vacuum pump is suitable for flammable gases because its design systematically eliminates the primary sources of ignition found in other pumps. The constant circulation of water provides isothermal (constant temperature) compression, preventing heat buildup, while the absence of internal metal-to-metal contact or oil lubrication removes potential friction sparks and secondary fuel sources.

The critical insight is that handling explosive gases isn't about managing risk—it's about eliminating it. A liquid ring vacuum pump is inherently safe because its operating principle—using a ring of liquid to compress gas—removes the heat and friction that could cause an explosion.

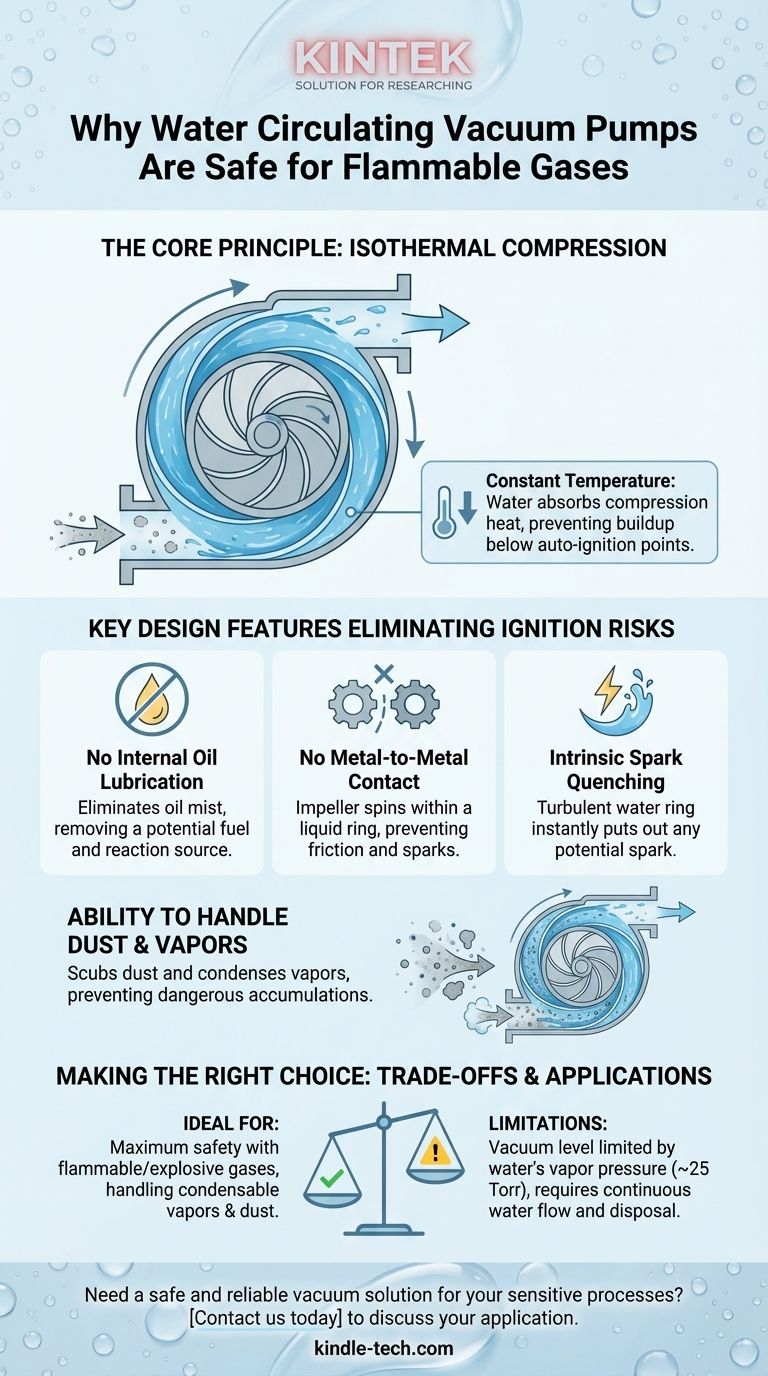

The Core Principle: Isothermal Compression

The safety of a liquid ring vacuum pump stems directly from how it works. It doesn't just manage heat; it uses a large volume of liquid to prevent heat from ever becoming a danger.

The Rotating Impeller and the Liquid Ring

Inside the pump casing, an impeller with multiple blades spins, but it is positioned off-center. As it spins, centrifugal force throws a sealant liquid (typically water) against the outer wall of the pump casing, forming a stable, concentric "liquid ring."

Creating Vacuum Without Friction

Because the impeller is eccentric, the pockets of space between the impeller blades and the liquid ring continuously change in volume. As a pocket rotates past the inlet port, it expands, creating a vacuum that draws gas in. As it continues to rotate, the pocket shrinks, compressing the gas before expelling it through the discharge port.

Critically, the only contact is between the gas and the water. There is no metal-to-metal contact between the impeller and the casing, eliminating a primary source of frictional heat and sparks.

Water's Role as a Heat Sink

Gas heats up when it is compressed. In a liquid ring pump, this heat is immediately absorbed by the large thermal mass of the circulating water. This process is nearly isothermal, meaning the gas temperature remains stable and well below its auto-ignition point.

Key Design Features That Eliminate Ignition Risk

Several specific design elements contribute to the pump's exceptional safety profile when handling flammable or explosive materials.

No Internal Oil Lubrication

Unlike oil-sealed rotary vane pumps, the pumping chamber of a liquid ring pump is sealed with water. This avoids the presence of oil mist, which can be a fuel source itself or react dangerously with certain process gases like oxygen.

Intrinsic Spark Quenching

The constant, turbulent presence of water in the pumping chamber acts as a natural quenching medium. In the unlikely event a spark were introduced into the pump (e.g., from static electricity in the inlet gas stream), the water would instantly extinguish it.

Ability to Handle Dust and Vapors

The pump's design also makes it highly effective at handling gases that contain condensable vapors or solid particles. The water can condense the vapors and scrub dust from the gas stream, preventing accumulations that might pose a secondary risk in other pump types.

Understanding the Trade-offs

While exceptionally safe, this pump technology is not the universal solution for every application. Understanding its limitations is key to proper selection.

Vacuum Level Limitations

The ultimate vacuum a liquid ring pump can achieve is limited by the vapor pressure of the sealant liquid. When using water at room temperature, the vacuum is typically limited to around 25 Torr (33 mbar). Using a liquid with a lower vapor pressure, like oil, can achieve deeper vacuums but may compromise the safety benefits.

Water Consumption and Disposal

The pump requires a continuous flow of cool sealant water to operate effectively. This water becomes contaminated with the process gas and may need to be treated before it can be disposed of or recirculated, adding an operational and environmental consideration.

Material Compatibility

The pump's materials of construction must be carefully selected to resist corrosion from both the process gas and the sealant liquid being used. An incorrect pairing can lead to pump failure.

Making the Right Choice for Your Application

Selecting the right vacuum pump requires matching the technology's inherent strengths and weaknesses to your primary goal.

- If your primary focus is maximum safety with flammable or explosive gases: The liquid ring vacuum pump is the standard choice due to its isothermal compression and lack of internal ignition sources.

- If your process gas contains condensable vapors or dust: The liquid ring pump's ability to ingest and handle these contaminants without damage makes it a robust and reliable option.

- If your primary focus is achieving a very deep vacuum (high vacuum range): You will likely need to consider a different technology, such as a dry screw pump or a multi-stage system, as the liquid ring pump is limited by its sealant's vapor pressure.

By understanding how this pump's fundamental design eliminates the elements of the fire triangle, you can confidently specify it for applications where safety is paramount.

Summary Table:

| Safety Feature | How It Eliminates Risk |

|---|---|

| Isothermal Compression | Circulating water absorbs heat, preventing gas temperature from reaching auto-ignition points. |

| No Internal Lubrication | Eliminates oil mist, removing a potential fuel source and reaction risk. |

| No Metal-to-Metal Contact | Impeller spins within a liquid ring, preventing friction sparks. |

| Intrinsic Spark Quenching | The turbulent water ring instantly extinguishes any potential sparks. |

Need a safe and reliable vacuum solution for your sensitive processes?

At KINTEK, we specialize in providing laboratory equipment, including robust vacuum pumps designed for handling hazardous materials. Our experts can help you select the right pump to ensure maximum safety and efficiency in your lab.

Contact us today to discuss your application and discover the KINTEK difference!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Variable Speed Peristaltic Pump

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What roles do water-cooling systems and stainless steel bottom plates serve? Master Heat Extraction in Solidification

- What is the role of ULT cooling equipment in gold nanoparticle hydrogel synthesis? Engineering Precise Nano-Architectures

- Why is a circulating cooling system indispensable in the PEO process? Ensure Coating Integrity and Bath Stability

- What is the necessity of a circulating water bath in chlorate production? Optimize Yield & Purity with Precision

- What is the necessity of condensing and cooling units in CO2 desorption? Optimize Solvent Recovery & Lab Safety

- In what types of systems are circulating pumps commonly used? The Essential Guide to Closed-Loop Systems

- Why is a cooling circulation system required for niobium material electropolishing? Essential Thermal Control Guide

- How do cooling systems impact bio-oil collection? Maximize Pyrolysis Yield with Precision Multi-Stage Quenching