The primary significance of a muffle furnace is its ability to create a high-temperature environment that completely isolates the material being heated from the byproducts of combustion and other contaminants. This is achieved through an internal chamber, or "muffle," which acts as a protective barrier, ensuring the purity and integrity of the sample during processes like ashing, heat treating, and chemical analysis.

A muffle furnace is fundamentally defined by its core function: providing a contaminant-free chamber for high-temperature applications. Its design prioritizes process purity and precise temperature control over direct heating, making it indispensable for sensitive scientific and industrial work.

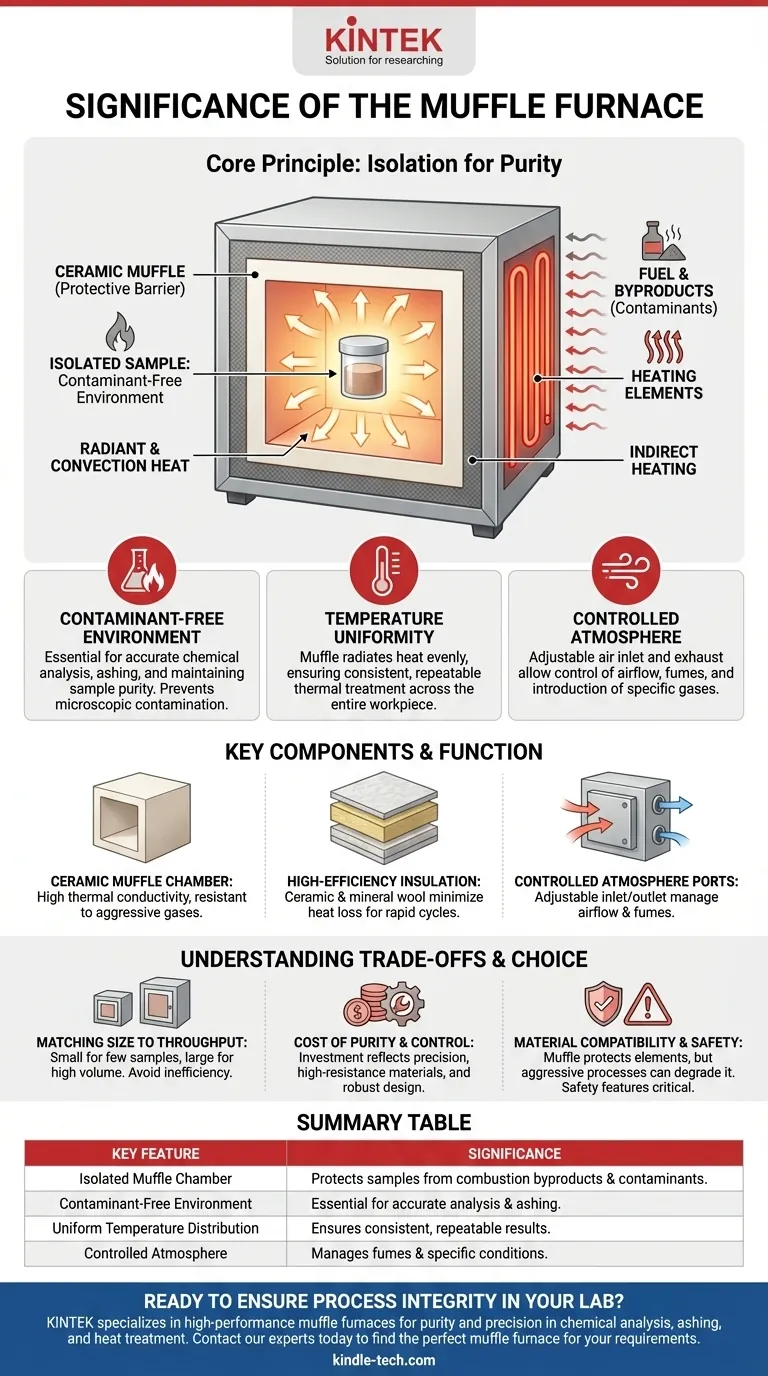

The Core Principle: Isolation for Purity

The defining characteristic of a muffle furnace is its internal muffle, which separates the workload from the heating elements and any potential contaminants. This design was developed specifically to solve the problem of sample contamination from fuel and combustion byproducts in high-temperature applications.

How the Muffle Achieves Isolation

The furnace's heating elements warm the muffle chamber, typically made of high-resistance ceramic. The material inside is then heated through a combination of radiant and convection heat transfer from the muffle's walls, not by direct exposure to the heat source.

This indirect heating method ensures that the sample is never touched by flames, fuel, or contaminants from the heating elements.

The Importance of a Contaminant-Free Environment

In many scientific and quality control processes, even microscopic contamination can invalidate results. The muffle furnace is crucial for applications like ashing, where the goal is to determine the precise percentage of noncombustible inorganic compounds in a sample.

The smooth, nearly particle-free surface of the ceramic muffle is essential for maintaining this pristine environment.

Ensuring Temperature Uniformity

Because the entire muffle chamber is heated, it radiates heat evenly onto the sample from all sides. Modern designs leverage this for excellent temperature uniformity, ensuring the entire workpiece receives the same thermal treatment for consistent, repeatable results.

Key Components and Their Function

A muffle furnace is more than just a hot box; its components are engineered for efficiency, safety, and precise control over the heating environment.

The Ceramic Muffle Chamber

The heart of the furnace is the embedded ceramic muffle. This component is specifically designed to have high thermal conductivity while being highly resistant to aggressive gases and vapors that might be released from the sample during heating.

High-Efficiency Insulation

To reach and maintain high temperatures efficiently, insulation is critical. Muffle furnaces use a combination of ceramic wool and mineral wool to minimize heat loss, ensuring rapid heating cycles and energy-efficient operation.

Controlled Atmosphere

Many models include an adjustable air inlet in the door and an exhaust outlet in the rear wall. This allows operators to control the flow of air through the chamber, managing fumes or introducing specific atmospheric conditions.

Understanding the Trade-offs

While highly effective, selecting and using a muffle furnace involves understanding its operational characteristics and choosing the right model for your specific needs.

Matching Furnace Size to Sample Throughput

The internal capacity of the furnace dictates its utility. A small furnace may only process a few samples at a time, while larger industrial models can handle dozens or hundreds. Choosing a furnace that is too large can be inefficient, while one that is too small creates a bottleneck.

The Cost of Purity and Control

The features that ensure purity—the high-resistance ceramic muffle, precise temperature controllers, and robust insulation—make these furnaces a specialized piece of equipment. The investment reflects the level of control and process integrity they provide.

Material Compatibility and Safety

While the muffle protects the heating elements, aggressive processes can still degrade the muffle itself over time. Furthermore, features like lift doors that face hot surfaces away from the operator are critical safety considerations for high-temperature work.

Making the Right Choice for Your Application

Your specific goal will determine which features of a muffle furnace are most important.

- If your primary focus is chemical analysis and ashing: Prioritize a furnace with a smooth, particle-free ceramic muffle and precise temperature controls to ensure sample purity and repeatable results.

- If your primary focus is metal heat treatment: Look for a furnace with excellent temperature uniformity and a robust chamber capable of handling the required temperatures for processes involving steel, copper, or other metals.

- If your primary focus is high-throughput laboratory work: Select a furnace size that matches your sample processing needs and has rapid heating and cooling cycles to maximize efficiency.

Ultimately, the muffle furnace is a specialized tool engineered to deliver process integrity where it matters most.

Summary Table:

| Key Feature | Significance |

|---|---|

| Isolated Muffle Chamber | Protects samples from combustion byproducts and contaminants. |

| Contaminant-Free Environment | Essential for accurate chemical analysis and ashing. |

| Uniform Temperature Distribution | Ensures consistent, repeatable results across the entire sample. |

| Controlled Atmosphere | Manages fumes and allows for specific atmospheric conditions. |

Ready to ensure process integrity in your lab?

KINTEK specializes in high-performance muffle furnaces designed for laboratories that demand purity and precision. Whether you're conducting sensitive chemical analysis, precise ashing, or consistent heat treatment, our equipment delivers the contaminant-free environment and uniform temperature control you need for reliable results.

Contact our experts today to find the perfect muffle furnace for your specific application and throughput requirements.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the power requirement for a muffle furnace? Ensure Safe and Efficient Operation

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage

- What is the use of muffle furnace in soil laboratory? Essential for Accurate Soil Organic Matter Analysis

- What are the materials used in a muffle furnace? A Guide to Durable Construction & Optimal Performance