At its core, the Sinter HIP process is a manufacturing technique that combines powder sintering and hot isostatic pressing (HIP) into a single, integrated thermal cycle. It uses high temperature and high-pressure inert gas to simultaneously consolidate metal or ceramic powders into a solid part, virtually eliminating all internal porosity. This results in components with near-perfect density and exceptional mechanical properties.

The central challenge in powder metallurgy is eliminating the tiny voids between powder particles. Sinter HIP solves this by applying uniform, high pressure during the final stages of sintering, collapsing these voids as the material fuses together to achieve superior strength and reliability in one efficient step.

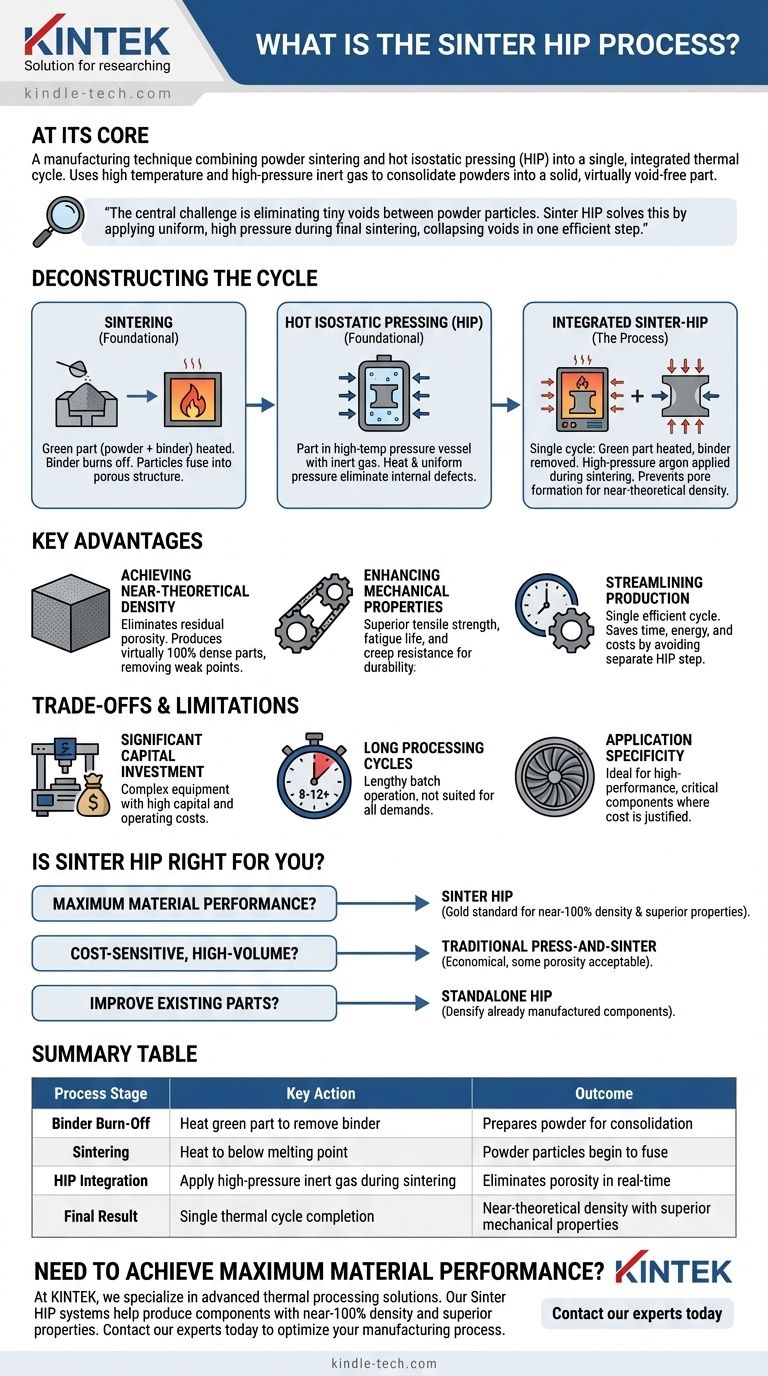

Deconstructing the Sinter HIP Cycle

To understand Sinter HIP, it's essential to first understand its two foundational processes: sintering and hot isostatic pressing.

The Role of Sintering

Sintering begins by forming a blend of material powder and a temporary binder into a desired shape, known as a "green part." This part is then heated in a furnace.

As the temperature rises, the binder burns away. Once hot enough—but still below the material's melting point—the surfaces of the powder particles begin to fuse, bonding them into a solid but still potentially porous structure.

The Role of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a process designed to densify components and eliminate internal defects. A part is placed in a high-temperature pressure vessel.

The vessel is filled with an inert gas, typically argon, and is heated and pressurized simultaneously. This combination of heat and uniform (isotropic) pressure collapses internal voids and porosity within the material.

The Integrated Sinter-HIP Process

Sinter HIP merges these two operations into a single, highly efficient cycle within one specialized piece of equipment.

The process starts with a green powder part. It is heated to burn off the binder, and then the temperature continues to rise toward the sintering point. At this stage, high-pressure argon is introduced into the furnace.

This applied pressure acts on the material as it sinters, preventing the formation of pores and closing off any that do form. The simultaneous heat and pressure ensure the part achieves near-theoretical density as the powder particles fuse together.

Key Advantages of the Integrated Process

Combining these steps provides significant benefits over traditional methods or performing the steps sequentially.

Achieving Near-Theoretical Density

The primary advantage is the elimination of residual porosity. By applying isostatic pressure during consolidation, Sinter HIP produces parts that are virtually 100% dense, removing the internal weak points that can lead to component failure.

Enhancing Mechanical Properties

This ultra-high density directly translates to superior material properties. Components processed with Sinter HIP exhibit significantly improved tensile strength, fatigue life, and creep resistance, making them more durable and reliable under extreme conditions.

Streamlining Production

Performing sintering and densification in a single cycle is far more efficient than a two-step process. It eliminates the need to cool, handle, and reheat the parts for a separate HIP cycle, saving significant time, energy, and operational costs.

Understanding the Trade-offs and Limitations

While powerful, the Sinter HIP process is not a universal solution. It involves specific trade-offs that make it suitable for certain applications over others.

Significant Capital Investment

The equipment required for Sinter HIP—a furnace capable of achieving both high temperatures and extreme pressures—is complex and represents a very high capital and operating cost. This is a major reason for its use in high-value industries.

Long Processing Cycles

A typical Sinter HIP cycle can last from 8 to 12 hours, or even longer, depending on the material and part size. While faster than a two-step process, it is still a lengthy batch operation not suited for all production demands.

Application Specificity

The process is primarily used for high-performance components where failure is not an option and the cost is justified. It is ideal for consolidating powders but is also used for improving castings and even rejuvenating used parts like turbine blades.

Is Sinter HIP the Right Choice for Your Project?

Selecting the right manufacturing process depends entirely on your project's performance requirements and economic constraints.

- If your primary focus is maximum material performance: Sinter HIP is the gold standard for achieving near-100% density and superior mechanical properties in powder metal or ceramic parts.

- If your primary focus is cost-sensitive, high-volume production: Traditional press-and-sinter methods may be more economical for applications where some residual porosity is acceptable.

- If your primary focus is improving existing cast or sintered parts: A standalone HIP cycle is the correct approach for densifying components that have already been manufactured.

By understanding this distinction, you can strategically select the most effective and economical path to achieve your component's required performance.

Summary Table:

| Process Stage | Key Action | Outcome |

|---|---|---|

| Binder Burn-Off | Heat green part to remove binder | Prepares powder for consolidation |

| Sintering | Heat to below melting point | Powder particles begin to fuse |

| HIP Integration | Apply high-pressure inert gas during sintering | Eliminates porosity in real-time |

| Final Result | Single thermal cycle completion | Near-theoretical density with superior mechanical properties |

Need to achieve maximum material performance for your high-value components?

At KINTEK, we specialize in advanced thermal processing solutions for laboratory and industrial applications. Our expertise in equipment like Sinter HIP systems can help you produce components with near-100% density, superior tensile strength, and enhanced fatigue life.

Whether you're working with metal powders, ceramics, or need to improve existing parts, KINTEK has the lab equipment and consumables to meet your demanding specifications.

Contact our experts today to discuss how our Sinter HIP solutions can optimize your manufacturing process and deliver exceptional reliability for your most critical applications.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature of a warm isostatic press? Achieve Optimal Densification for Your Materials

- What is the application of isostatic pressing? Achieve Uniform Density in High-Performance Components

- How does Hot Isostatic Pressing (HIP) enhance CuNiCoZnAlTi properties? Achieve Theoretical Density & Maximum Strength

- What is the hot isostatic process? Achieve Perfect Material Density for Critical Components

- What is the purpose of using 160 MPa pressure in HIP for Inconel 718? Achieve Aerospace-Grade Alloy Density

- When was hot isostatic pressing invented? The 1955 Breakthrough for Superior Material Integrity

- What are the parameters of HIP process? Master Temperature, Pressure, and Time for Superior Densification

- How do warm isostatic presses improve dry electrode performance? Enhance ASSB Conductivity with Heat & Pressure