The short answer is that there is no single document called "the standard" for aluminum heat treatment. Instead, the industry uses a standardized coding system, known as temper designations, to define the exact sequence of thermal and mechanical processes an aluminum alloy has undergone. This system, managed by The Aluminum Association, uses a letter followed by one or more numbers (e.g., 6061-T6) to communicate the material's final mechanical properties.

Understanding the aluminum temper designation system is the key to specifying heat treatment. This code doesn't just name a process; it describes the material's entire thermomechanical history and, consequently, its final strength, hardness, and ductility.

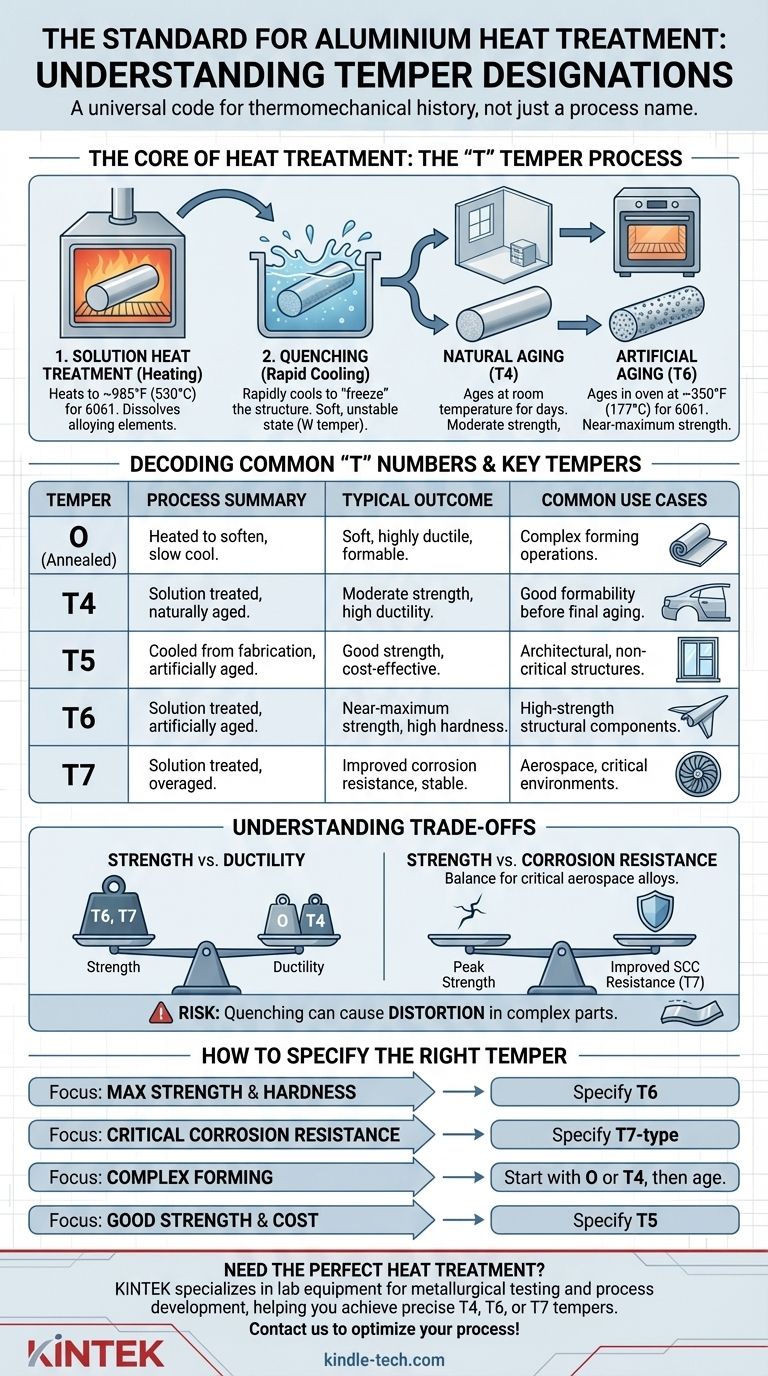

The Foundation: The Temper Designation System

The temper designation is a suffix appended to the alloy number, like the "T6" in 6061-T6. This simple code is a universal language for engineers, metallurgists, and machinists.

The Basic Designations

There are five main temper designation families, each denoted by a letter. Only one, the "T" series, always involves heat treatment to produce hardening.

- F - As Fabricated: This applies to products with no special control over their thermal or strain-hardening conditions. There are no guaranteed mechanical properties.

- O - Annealed: This is the softest, most ductile temper. It is achieved by heating the alloy to allow its crystal structure to reform, relieving stress and maximizing workability.

- H - Strain-Hardened: This applies only to non-heat-treatable alloys (like the 3xxx or 5xxx series). Strength is increased by physically working the metal (e.g., rolling or drawing) at cold temperatures.

- W - Solution Heat-Treated: This is a rare and unstable temper. It represents the state immediately after solution heat treatment and quenching, before any aging has occurred. It is typically only specified for internal process control.

Unpacking the "T" Designation: The Core of Heat Treatment

The "T" temper is what most people mean when they refer to heat-treated aluminum. It applies to heat-treatable alloys (like the 2xxx, 6xxx, and 7xxx series) and signifies that the material has been strengthened through a specific thermal process.

The Three-Step Process for "T" Tempers

Achieving a stable "T" temper involves a precise, three-stage process called precipitation hardening.

- Solution Heat Treatment (Heating): The aluminum is heated to a specific high temperature (e.g., ~985°F / 530°C for 6061) and held there. This dissolves the major alloying elements (like magnesium and silicon) into a solid solution, much like dissolving sugar in hot water.

- Quenching (Rapid Cooling): The material is then rapidly cooled, usually in water. This "freezes" the alloying elements in place, creating a supersaturated solid solution. The material is now in a soft, unstable state (the "W" temper).

- Aging (Precipitation Hardening): The material is held for a period of time, either at room temperature or in a low-temperature oven. During this stage, the dissolved alloying elements precipitate out of the solution as extremely fine, dispersed particles that obstruct dislocation movement, dramatically increasing the alloy's strength and hardness.

Natural vs. Artificial Aging

The final properties are determined by how the aging step is performed.

- Naturally Aged (T4): After quenching, the part is left to age at room temperature for several days. This results in a moderately strong and highly ductile temper.

- Artificially Aged (T6): After quenching, the part is placed in an oven at a low temperature (e.g., ~350°F / 177°C for 6061) for several hours. This accelerates and controls precipitation, resulting in near-maximum strength and hardness.

Decoding Common "T" Numbers

The number following the "T" provides more detail about the specific process.

- T4: Solution heat-treated and naturally aged to a substantially stable condition.

- T5: Cooled from an elevated temperature manufacturing process (like extrusion) and then artificially aged. This is a lower-cost option that achieves good strength but is not as strong as T6.

- T6: Solution heat-treated and then artificially aged. This is the most common high-strength temper for many alloys.

- T7: Solution heat-treated and then overaged (artificially aged past peak strength). This is done intentionally to improve dimensional stability and resistance to stress corrosion cracking.

Understanding the Trade-offs

Choosing a temper designation is an engineering decision that involves balancing competing properties. It is never about simply picking the "strongest" option.

Strength vs. Ductility

The primary trade-off is between strength and ductility. An O-temper (annealed) part is soft and easy to form, but weak. A T6-temper part is very strong but brittle and cannot be easily formed.

Strength vs. Corrosion Resistance

For certain alloys, particularly in the 7xxx series used in aerospace, peak strength comes with a higher susceptibility to stress corrosion cracking (SCC). A T7-type temper intentionally sacrifices some strength to significantly improve SCC resistance, making it a safer choice for critical components.

The Risk of Distortion

The rapid cooling during the quenching step is a thermal shock that induces significant internal stress. This often causes thin or complex parts to warp. This distortion may need to be corrected through straightening or subsequent stress-relief operations.

How to Specify the Right Temper

Your choice of temper must be driven by the part's function, manufacturing process, and service environment.

- If your primary focus is maximum strength and hardness: Specify a T6 temper, as this develops the highest practical strength for most common alloys.

- If your primary focus is corrosion resistance in a critical environment: Specify a T7-type temper (e.g., T73, T76) to gain stability and resistance to stress corrosion cracking, accepting a minor reduction in strength.

- If your primary focus is forming a complex shape: Start with the material in an O-temper or T4-temper, perform the forming operations, and then perform the final aging process.

- If your primary focus is a balance of good strength and lower cost: A T5 temper is often sufficient for architectural or non-critical structural applications where the extreme performance of a T6 is not required.

Ultimately, mastering aluminum heat treatment is about using this standard designation system to precisely match the material's properties to the demands of your application.

Summary Table:

| Temper Designation | Key Process | Typical Outcome | Common Use Cases |

|---|---|---|---|

| O (Annealed) | Heated to soften | Soft, highly ductile | Complex forming operations |

| T4 | Solution heat-treated, naturally aged | Moderate strength, high ductility | Good formability before final aging |

| T5 | Cooled from fabrication, artificially aged | Good strength, cost-effective | Architectural, non-critical structures |

| T6 | Solution heat-treated, artificially aged | Near-maximum strength, high hardness | High-strength structural components |

| T7 | Solution heat-treated, overaged | Improved corrosion resistance, stable | Aerospace, critical environments |

Need to specify the perfect aluminum heat treatment for your project?

KINTEK specializes in lab equipment and consumables for metallurgical testing and process development. Our experts can help you select the right furnaces and tools to achieve precise T4, T6, or T7 tempers, ensuring your aluminum components meet exact strength, ductility, and corrosion resistance requirements.

Contact our team today to discuss your application and optimize your heat treatment process!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the tubes in a furnace called? Understanding the Role of the Working Tube

- What are the advantages of a tube furnace? Achieve Superior Temperature Uniformity and Control

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material