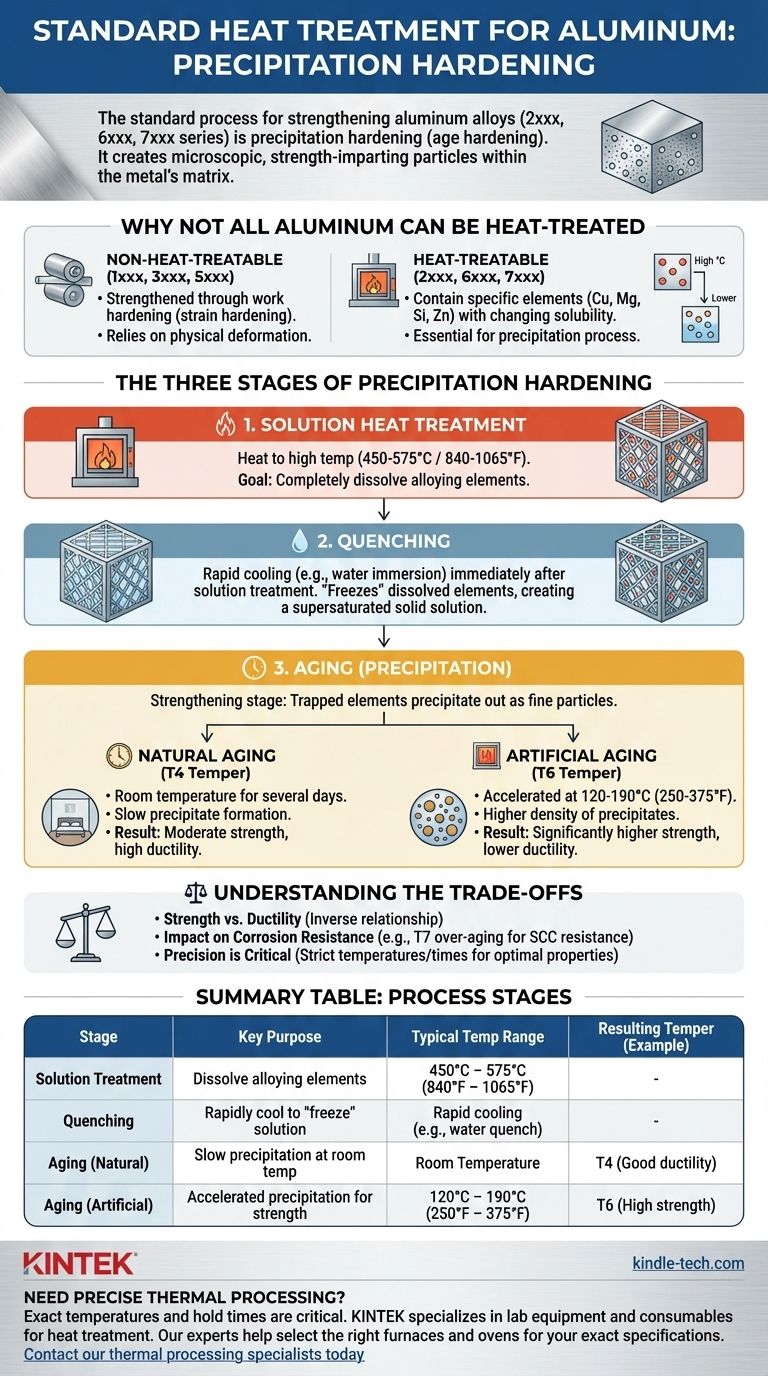

The standard heat treatment for strengthening applicable aluminum alloys is a multi-stage process called precipitation hardening, also known as age hardening. Unlike the hardening of steel, which relies on phase changes in the iron-carbon crystal structure, this process works by creating microscopic, strength-imparting particles within the aluminum's metallic matrix.

The core principle of heat-treating aluminum is not to make the metal itself harder, but to precisely control the formation and distribution of alloying element "precipitates." These tiny particles act as obstacles within the metal's grain structure, blocking internal movement and dramatically increasing the material's overall strength and hardness.

Why Not All Aluminum Can Be Heat-Treated

A common point of confusion is the assumption that all aluminum alloys can be strengthened through heat treatment. The ability to be precipitation hardened depends entirely on the alloy's chemical composition.

Work Hardening vs. Heat Treating

Alloys in the 1xxx, 3xxx, and 5xxx series are considered non-heat-treatable. They gain their strength through strain hardening (also known as work hardening), which involves physically deforming the metal by rolling or drawing it at a cold temperature.

The Role of Specific Alloying Elements

Heat-treatable alloys, primarily in the 2xxx, 6xxx, and 7xxx series, contain specific elements like copper, magnesium, silicon, and zinc. These elements have changing solubility in aluminum at different temperatures, a property that is essential for the precipitation process to work.

The Three Stages of Precipitation Hardening

The process is a precise thermal sequence. Each stage serves a distinct and critical purpose in developing the final mechanical properties of the alloy.

Stage 1: Solution Heat Treatment

The first step is to heat the alloy to a high, uniform temperature—typically between 450 to 575°C (840 to 1065°F), depending on the specific alloy.

The goal here is to dissolve the alloying elements completely into the aluminum, creating a "solid solution." This is analogous to dissolving sugar in hot water; the elements are evenly distributed throughout the metallic structure.

Stage 2: Quenching

Immediately after solution heat treatment, the material is rapidly cooled, usually by immersion in water. This is a critical, time-sensitive step.

The rapid quench "freezes" the dissolved alloying elements in place, creating a supersaturated solid solution. The elements are trapped within the aluminum lattice and do not have time to precipitate out.

Stage 3: Aging (Precipitation)

This is the final stage where the actual strengthening occurs. The trapped alloying elements begin to precipitate out of the solution, forming extremely fine, uniformly dispersed particles. This is done in one of two ways.

Natural Aging (T4 Temper): This occurs by letting the material sit at room temperature for several days. The precipitates form slowly, resulting in a moderately strong and highly ductile material.

Artificial Aging (T6 Temper): This process is accelerated by heating the material to a relatively low temperature—typically 120 to 190°C (250 to 375°F)—and holding it for a set period. This produces a greater number and density of precipitates, resulting in significantly higher strength and hardness, often with a slight reduction in ductility.

Understanding the Trade-offs

Specifying a heat treatment is not just about maximizing strength; it involves a series of engineering trade-offs that impact performance.

Strength vs. Ductility

There is almost always an inverse relationship between strength and ductility. An artificially aged T6 temper will be much stronger but less forgiving and more brittle than a naturally aged T4 temper of the same alloy.

Impact on Corrosion Resistance

The heat treatment process can alter an alloy's resistance to corrosion. For example, in some 7xxx series alloys, an "over-aging" process (T7 temper) is intentionally used to improve resistance to stress corrosion cracking (SCC), albeit with a slight reduction in peak strength compared to the T6 temper.

The Critical Need for Precision

The temperatures and time intervals for each stage are strictly defined for each alloy. Minor deviations can result in incomplete solutionizing, improper precipitate formation, or internal stresses, all of which lead to substandard mechanical properties and potential part failure.

Making the Right Choice for Your Goal

Selecting the correct alloy and temper is fundamental to a successful design. Your decision should be guided by the primary performance requirement of the component.

- If your primary focus is maximum strength and hardness: Specify a fully artificially aged temper, such as 6061-T6 or 7075-T6.

- If your primary focus is formability before strengthening: Procure the material in an annealed (O) or freshly quenched (T4) state, form the part, and then perform the artificial aging process.

- If your primary focus is balancing strength with fracture toughness: Consider a naturally aged T4 temper or a specialized temper designed for damage tolerance.

- If your primary focus is stress corrosion cracking resistance in a 7xxx alloy: Specify an over-aged temper like T73 or T76 instead of the peak-strength T6.

- If heat treatment is not feasible or necessary: Select a non-heat-treatable alloy from the 3xxx or 5xxx series and specify the desired level of strain hardening (e.g., H32, H34).

Understanding this process empowers you to select and specify the precise aluminum alloy and temper to meet your project's performance demands.

Summary Table:

| Heat Treatment Stage | Key Purpose | Typical Temperature Range | Resulting Temper (Example) |

|---|---|---|---|

| Solution Treatment | Dissolve alloying elements | 450°C – 575°C (840°F – 1065°F) | - |

| Quenching | Rapidly cool to "freeze" solution | Rapid cooling (e.g., water quench) | - |

| Aging (Natural) | Slow precipitation at room temperature | Room Temperature | T4 (Good ductility) |

| Aging (Artificial) | Accelerated precipitation for strength | 120°C – 190°C (250°F – 375°F) | T6 (High strength) |

Need precise thermal processing for your aluminum components? The exact temperatures and hold times are critical for achieving the desired material properties. KINTEK specializes in lab equipment and consumables for materials testing and heat treatment processes. Our experts can help you select the right furnaces and ovens to ensure your aluminum alloys meet exact specifications. Contact our thermal processing specialists today to discuss your application requirements.

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What is a general purpose laboratory oven? A Guide to Drying, Sterilizing, and Curing

- What are the methods of oil sludge treatment? A Guide to Recovery, Disposal & Cost

- How does an incubator shaker affect the yield of reducing sugars? Optimize Pennisetum alopecuroides Hydrolysis

- What is the range of sputtering? Achieve High-Quality Thin Films for Any Application

- What are the disadvantages of wiped film molecular still? High Cost, Complexity & Separation Limits

- How does DNA storage at -20°C and -80°C compare? Ensure Long-Term Sample Integrity

- What are the advantages of sintered components? Achieve Cost-Effective, Complex Parts with Minimal Waste

- What are the two types of casting machines? Hot-Chamber vs. Cold-Chamber Die Casting