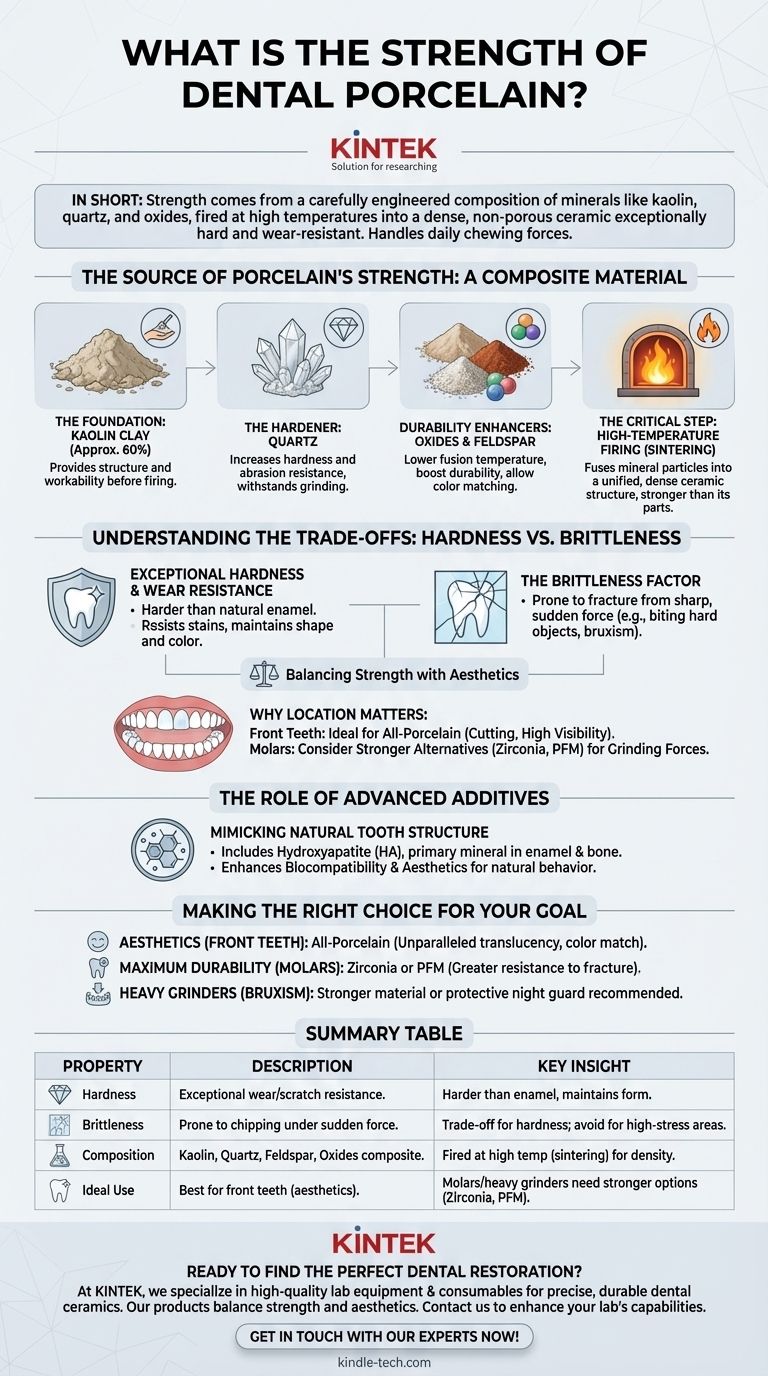

In short, the strength of dental porcelain comes from its carefully engineered composition of minerals like kaolin, quartz, and various oxides. These raw materials are mixed and then fired at extremely high temperatures, fusing them into a dense, non-porous ceramic that is exceptionally hard and resistant to wear. This process creates a material that can withstand the significant forces of daily chewing.

The central challenge in dental materials is balancing strength with aesthetics. Dental porcelain excels in hardness and appearance, but its key trade-off is brittleness. Understanding this distinction is crucial for determining its suitability for different dental restorations.

The Source of Porcelain's Strength: A Composite Material

Dental porcelain is not a single substance but a composite ceramic. Its final strength is a result of both its specific ingredients and the manufacturing process it undergoes.

The Foundation: Kaolin Clay

The primary component, often making up around 60% of the mixture, is a pure form of clay called kaolin. This material provides the foundational structure and workability needed to form a crown or veneer before it is fired.

The Hardener: Quartz

To increase the material's final hardness and resistance to abrasion, quartz is added. Quartz is an extremely hard mineral, and its inclusion significantly boosts the porcelain's ability to withstand the grinding wear of chewing.

Durability Enhancers: Oxides and Feldspar

Other additives, such as feldspar and various metallic oxides, serve multiple purposes. They help lower the fusion temperature during firing and contribute to the final durability of the material, all while allowing for precise color matching to your natural teeth.

The Critical Step: High-Temperature Firing

The individual ingredients are not inherently strong on their own. The true strength is unlocked when the mixture is fired in a dental furnace at high temperatures. This process, known as sintering, fuses the mineral particles together, creating a unified, dense ceramic structure that is much stronger than the sum of its parts.

Understanding the Trade-offs: Hardness vs. Brittleness

To make an informed decision, you must understand the two key mechanical properties of porcelain: its hardness and its brittleness.

Exceptional Hardness and Wear Resistance

Dental porcelain is harder than natural tooth enamel. This gives it outstanding resistance to wear and an inability to be stained by coffee, tea, or other foods. Your porcelain restoration will maintain its shape and color for many years.

The Brittleness Factor

However, porcelain is also a brittle material. Hardness measures resistance to scratching and wear, while brittleness describes a material's tendency to fracture when subjected to a sharp, sudden force. Think of glass: it's very hard to scratch, but it shatters if dropped. Porcelain can chip or crack under excessive pressure, such as from habitual teeth grinding or biting down on an olive pit.

Why Location Matters in the Mouth

This trade-off is why the location of the restoration is critical. For front teeth, which handle cutting and are highly visible, all-porcelain crowns and veneers are often ideal. For molars, which endure immense grinding forces, your dentist might recommend a stronger alternative like zirconia or a porcelain-fused-to-metal (PFM) crown that has a supportive metal substructure.

The Role of Advanced Additives

Modern dental porcelains continue to evolve with the inclusion of specialized minerals to improve their properties.

Mimicking Natural Tooth Structure

Some advanced ceramics include hydroxyapatite (HA). This is significant because HA is the primary mineral that makes up natural tooth enamel and bone. Including it in the porcelain mixture helps create a material that is highly biocompatible.

Enhancing Biocompatibility and Aesthetics

The goal of these additives is to create a restoration that not only looks natural but also behaves more like a natural tooth within the oral environment. This contributes to both long-term health and superior aesthetics.

Making the Right Choice for Your Goal

The decision to use an all-porcelain restoration depends entirely on your specific needs and oral health.

- If your primary focus is aesthetics for front teeth: All-porcelain is an excellent choice, offering unparalleled translucency and color-matching with sufficient strength for normal biting forces.

- If your primary focus is maximum durability for molars: You should discuss options like zirconia or porcelain-fused-to-metal (PFM) with your dentist, as they offer greater resistance to fracture under heavy chewing.

- If you are a heavy teeth grinder (bruxism): Porcelain may be more prone to chipping, and a stronger material or a protective night guard will likely be recommended regardless of the restoration type.

Understanding the specific strengths and limitations of dental porcelain empowers you to have a more productive conversation with your dentist about the ideal solution for your long-term dental health.

Summary Table:

| Property | Description | Key Insight |

|---|---|---|

| Hardness | Exceptional resistance to wear and scratching. | Harder than natural tooth enamel, maintains shape and color. |

| Brittleness | Prone to chipping or cracking under sudden, sharp force. | Trade-off for hardness; not ideal for high-stress areas like molars. |

| Composition | Composite of kaolin, quartz, feldspar, and oxides. | Fired at high temperatures (sintering) to create a dense, strong structure. |

| Ideal Use | Best for front teeth (crowns, veneers) where aesthetics are paramount. | For molars or heavy grinders, consider zirconia or PFM crowns for added strength. |

Ready to find the perfect dental restoration for your needs?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables essential for creating precise and durable dental ceramics. Our products support dental labs in achieving the perfect balance of strength and aesthetics in every restoration.

Whether you're crafting all-porcelain veneers or stronger zirconia crowns, KINTEK has the reliable tools and materials you need. Contact us today to learn how we can help enhance your lab's capabilities and deliver superior results for your patients.

Get in touch with our experts now!

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- What is the temperature of the burnout oven? Master the Multi-Stage Cycle for Flawless Castings

- What is the sintering temperature of yttria stabilized zirconia? Master the Thermal Cycle for Superior Results

- What is the primary function of a dental sintering furnace? Transform Zirconia into Durable Crowns & Bridges

- What is a dental furnace? The Precision Oven for Creating Strong, Lifelike Dental Restorations

- What is sintering dentistry? The Key to Strong, Aesthetic Dental Restorations

- How can a porcelain furnace be calibrated using a visual indicator approach? Master Material-Specific Accuracy

- What is a recommended maintenance practice for modern ceramic furnaces? Prioritize Firmware Updates for Peak Performance

- What is the difference between zirconia and ceramic? A Guide to Choosing the Right Dental Crown