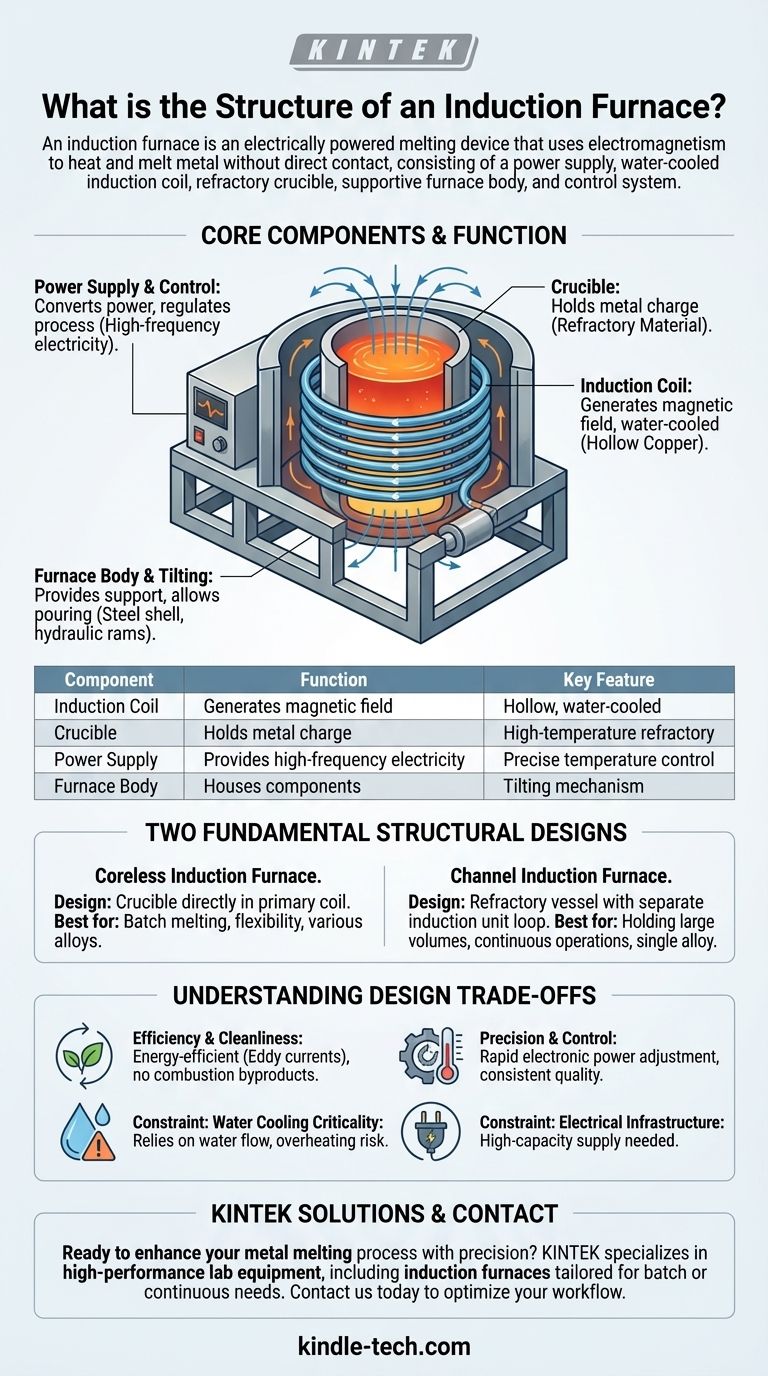

At its core, an induction furnace is an electrically powered melting device that uses the principles of electromagnetism to heat and melt metal without direct contact or combustion. Its structure consists of a power supply, a water-cooled induction coil, a refractory crucible to hold the metal, a supportive furnace body, and a control system to manage the entire process.

The structure of an induction furnace is fundamentally designed to act as an electrical transformer. The furnace's coil serves as the primary winding, and the metal charge inside the crucible acts as a single-turn secondary winding, which heats itself through internally generated currents.

The Core Components and Their Function

To understand the furnace, we must first understand its individual parts and the role each plays in the melting process. Each component is critical for the system's efficiency, safety, and reliability.

The Induction Coil

The heart of the furnace is the induction coil. It is a helical coil typically made from high-conductivity hollow copper tubing.

An alternating electrical current from the power supply flows through this coil, generating a powerful and rapidly reversing magnetic field in the center of the furnace.

Crucially, water is constantly circulated through the hollow copper tubing. This is essential to remove the immense waste heat generated by the electrical current, protecting the coil from melting itself.

The Crucible

Positioned inside the induction coil is the crucible. This is a cylindrical, open-topped container made from refractory materials, which are ceramics designed to withstand extreme temperatures.

The crucible's primary function is to contain the solid metal charge and the subsequent molten bath. It must be chemically inert to avoid contaminating the metal and strong enough to handle the thermal and physical stresses of the operation.

The Power Supply and Control System

The power supply is the engine of the furnace. It converts standard utility power into the high-current, specific-frequency electricity needed to drive the induction coil. This unit often includes a transformer, a capacitor bank, and an inverter.

The control system is the brain. It uses integrated circuits and sensors to regulate the power output, monitor system parameters, and ensure safe operation. This system provides protection against over-current, over-voltage, and cooling system failures, and allows operators to achieve precise temperature control.

The Furnace Body and Tilting Mechanism

The entire assembly of the coil and crucible is housed within a rigid steel shell or frame. This body provides structural support.

In many designs, this shell includes magnetic shielding to prevent the strong magnetic field from inducing heat in the supporting structure itself, which would be inefficient and hazardous.

The furnace body is typically mounted on trunnions, which act as a pivot point. This allows the entire furnace to be tilted by hydraulic rams, enabling the safe and controlled pouring of molten metal into a ladle or mold.

Two Fundamental Structural Designs

While the core principles remain the same, induction furnaces are built in two primary configurations, each suited for different applications.

The Coreless Induction Furnace

This is the most common design, especially in foundries. The structure is exactly as described above: a crucible is placed directly within the primary induction coil.

This design is highly effective for batch melting, where a specific quantity of metal is melted, poured, and the process is repeated. It offers high power density and the flexibility to melt different alloys, as the crucible can be completely emptied between melts.

The Channel Induction Furnace

In a channel furnace, the main vessel is simply a refractory-lined container for holding molten metal. Attached to the side or bottom is a separate induction unit.

This unit contains an iron core (like a traditional transformer) with an induction coil. A channel of molten metal from the main vessel loops through this unit, acting as the transformer's secondary circuit. The current induced in this small loop heats the metal, which then circulates back into the main bath.

This structure is ideal for holding large volumes of molten metal at a constant temperature or for superheating. It is more energy-efficient for continuous or semi-continuous operations with a single alloy.

Understanding the Design's Trade-offs

The structure of an induction furnace provides distinct advantages, but also introduces critical operational considerations.

Advantage: Efficiency and Cleanliness

Because the heat is generated directly within the metal charge via eddy currents (Joule heating), the process is extremely energy-efficient.

Furthermore, since there is no combustion, the process is clean, producing no smoke, ash, or harmful byproducts. This simplifies environmental compliance and results in a higher-purity melt.

Advantage: Precision and Control

The electronic control system allows for the precise and rapid adjustment of power input. This gives operators exceptional control over the melting rate and final temperature, leading to consistent metallurgical quality.

Constraint: Criticality of Water Cooling

The structure's reliance on a water-cooled coil is its primary vulnerability. Any interruption to the cooling water flow while the furnace is under power can cause the coil to overheat and fail catastrophically in seconds.

Constraint: Electrical Infrastructure Demands

Induction furnaces are power-intensive devices. Their structure requires a robust, high-capacity electrical supply and grid connection, which represents a significant infrastructure requirement for any facility.

Making the Right Choice for Your Goal

The optimal furnace structure is dictated entirely by your operational needs and metallurgical goals.

- If your primary focus is flexibility and batch melting of various alloys: The simple, powerful structure of a coreless induction furnace is the superior choice.

- If your primary focus is holding and maintaining the temperature of a large, single-alloy bath: The continuous, high-efficiency structure of a channel induction furnace is better suited for the task.

Understanding this direct relationship between structure and function empowers you to select and operate the right tool for your specific application.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Induction Coil | Generates magnetic field to heat metal | Hollow, water-cooled copper tubing |

| Crucible | Holds the metal charge | Made from high-temperature refractory material |

| Power Supply | Provides high-frequency electricity | Enables precise temperature control |

| Furnace Body | Houses components and provides structure | Often includes tilting mechanism for pouring |

Ready to enhance your metal melting process with precision and efficiency?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for reliability and superior results. Whether you need a coreless furnace for batch melting or a channel furnace for continuous operations, our solutions are tailored to meet your laboratory's specific needs.

Contact us today to discuss how our induction furnaces can optimize your workflow and deliver the purity and control your applications demand.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process