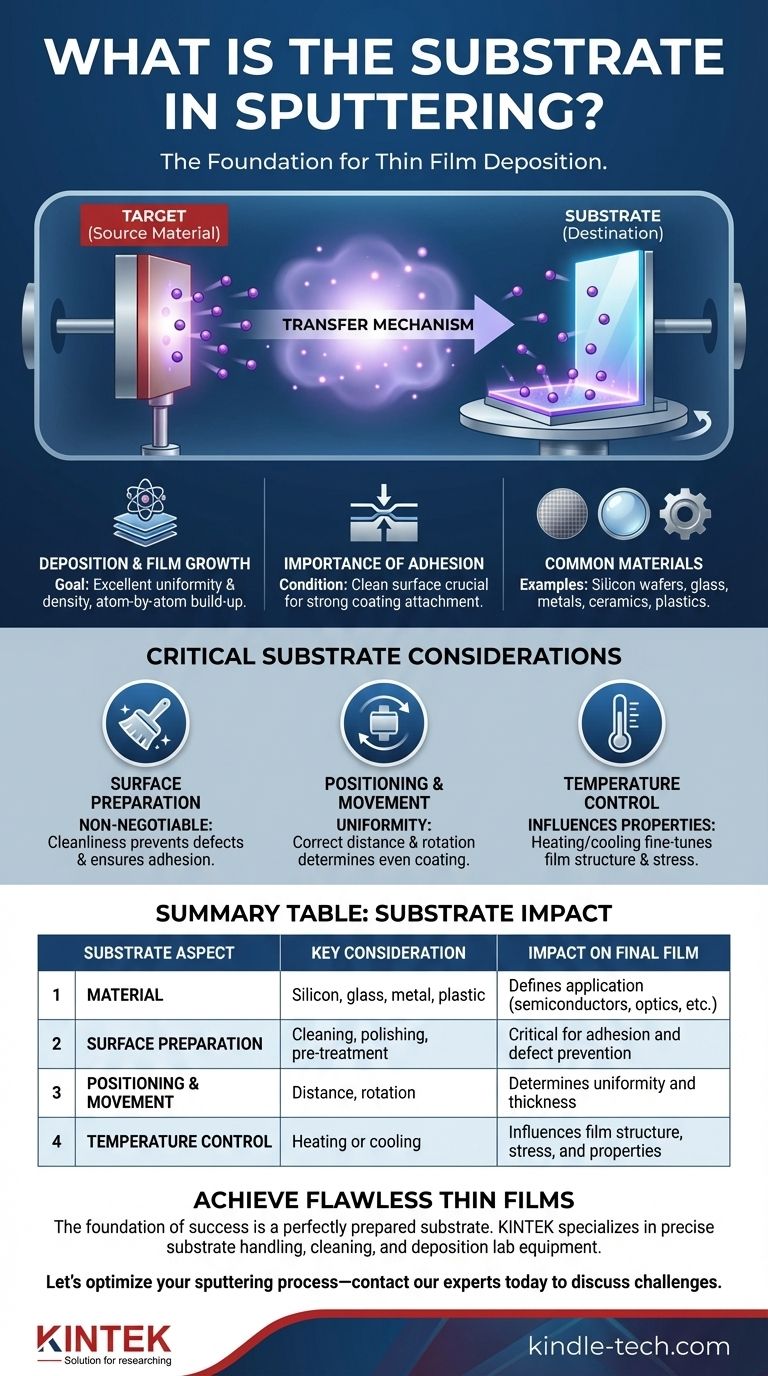

In sputtering, the substrate is the material, surface, or object onto which a new thin film is deposited. It serves as the foundation for the coating being created. During the process, atoms are ejected from a source material (the target) and travel through a vacuum to land and build up on the substrate, forming a new, ultra-thin layer.

The core concept to grasp is that sputtering is a transfer process. The substrate is not the source of the material, but rather the destination—it is the canvas upon which the thin film is meticulously "painted," atom by atom.

The Role of the Substrate in the Sputtering System

To understand the substrate's function, it helps to see its place within the three key components of any sputtering process. These elements work together inside a vacuum chamber to create a high-purity coating.

The Target: The Source Material

The target is a block of the material you want to create a film from. This could be a metal, a ceramic, or another compound. It is the source of the atoms for the new coating.

The Plasma: The Transfer Mechanism

An inert gas, typically Argon, is introduced into the vacuum chamber and energized to create a plasma. The positively charged ions from this plasma are accelerated and slammed into the target.

The Substrate: The Destination

This energetic bombardment knocks atoms loose from the target. These ejected atoms travel through the vacuum and land on the substrate, which has been strategically placed to intercept them. This slow, steady accumulation of atoms forms the thin film.

How the Substrate Influences the Final Film

The substrate is far more than a passive holder; its condition and properties are critical to the quality of the final product. The interaction between the arriving atoms and the substrate surface defines the film's characteristics.

Deposition and Film Growth

As atoms from the target arrive at the substrate, they begin to form a layer. The goal is to create a film with excellent uniformity (the same thickness everywhere) and density (no gaps or voids).

The Importance of Adhesion

A successful coating must stick firmly to the surface. This adhesion is highly dependent on the substrate's condition. A perfectly clean, prepared substrate surface allows the deposited atoms to form strong bonds.

Common Substrate Materials

The versatility of sputtering allows it to be used on an enormous range of materials. Common examples include silicon wafers for semiconductors, glass for optical lenses and displays, and various metals or plastics for protective or decorative finishes.

Critical Substrate Considerations

Achieving a high-quality sputtered film requires careful control over the substrate. Ignoring these factors is a common point of failure in the process.

Surface Preparation is Non-Negotiable

The single most critical factor is substrate cleanliness. Any microscopic dust, oil, or other contaminant will act as a barrier, preventing the deposited film from adhering properly and creating defects.

Substrate Positioning and Movement

The placement of the substrate relative to the target determines the uniformity of the coating. Often, substrates are rotated or moved during deposition to ensure every part of the surface receives an even layer of material.

Temperature Control

The temperature of the substrate during deposition can significantly impact the film's structure and properties. Heating or cooling the substrate is a common technique used to fine-tune the final result, affecting everything from crystal structure to internal stress.

Choosing and Preparing Your Substrate

The ideal substrate is always defined by the final application. Your choice will dictate the necessary preparation steps and process parameters.

- If your primary focus is high-performance optics: Your substrate will likely be glass or a crystal, where surface smoothness and a flawless, multi-stage cleaning process are paramount.

- If your primary focus is semiconductors: Your substrate will be a silicon wafer, and the entire process is dominated by the need for extreme purity and atomic-level cleanliness.

- If your primary focus is a durable or decorative coating: Your substrate could be metal, ceramic, or plastic, where surface texturing and pre-treatments are often used to maximize adhesion and longevity.

Ultimately, treating the substrate as an active and critical component of the system—not just a passive surface—is the key to achieving a successful and reliable sputtered coating.

Summary Table:

| Substrate Aspect | Key Consideration | Impact on Final Film |

|---|---|---|

| Material | Silicon, glass, metal, plastic | Defines application (e.g., semiconductors, optics) |

| Surface Preparation | Cleaning, polishing, pre-treatment | Critical for film adhesion and defect prevention |

| Positioning & Movement | Distance from target, rotation | Determines coating uniformity and thickness |

| Temperature Control | Heating or cooling during deposition | Influences film structure, stress, and properties |

Achieve flawless thin films with the right substrate preparation. The foundation of any successful sputtering process is a perfectly prepared substrate. KINTEK specializes in providing the lab equipment and consumables necessary for precise substrate handling, cleaning, and deposition. Whether you are working with silicon wafers, optical glass, or industrial components, our expertise ensures your substrates are optimized for superior adhesion and performance. Let's optimize your sputtering process—contact our experts today to discuss your specific substrate and coating challenges.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

- Float Soda-Lime Optical Glass for Laboratory Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition