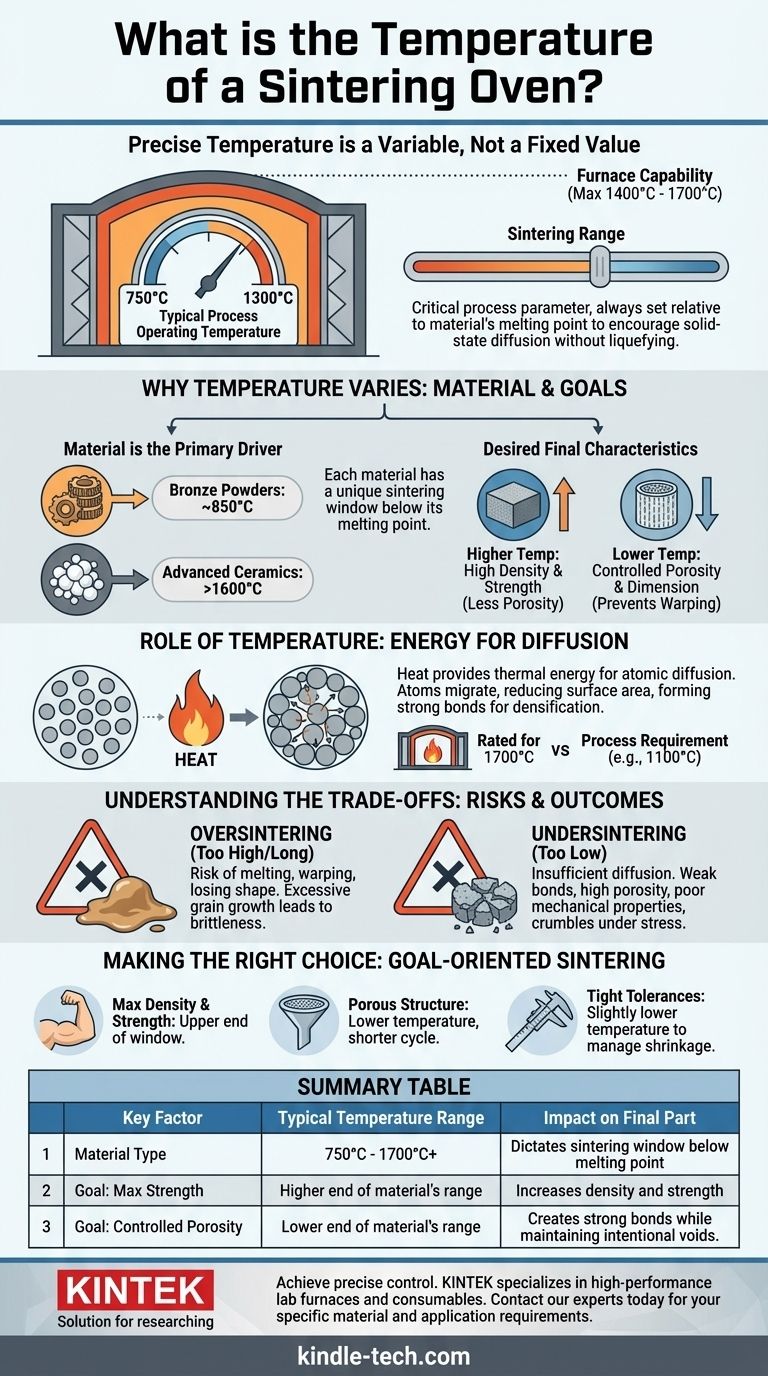

The precise temperature of a sintering oven is not a single value but a carefully controlled variable. While a standard sintering furnace may be capable of reaching maximum temperatures between 1400°C and 1700°C, the actual operating temperature for a specific process typically falls within a much wider range of 750°C to 1300°C. This temperature is dictated entirely by the material being processed and the final properties you need to achieve.

The core principle to understand is that sintering temperature is a critical process parameter, not a fixed oven setting. It is always set relative to the material's melting point to encourage solid-state diffusion, which fuses particles together without liquefying them.

Why Temperature Varies So Drastically

The vast temperature range seen in sintering reflects the diversity of materials used in the process. The ideal temperature is a delicate balance between providing enough energy for particles to bond and avoiding enough energy to cause them to melt.

The Material is the Primary Driver

Every material has a unique sintering window. This is the temperature range where atoms have enough energy to diffuse across particle boundaries, effectively welding them together.

Sintering fundamentally occurs below the material's melting point. For example, certain bronze powders might sinter around 850°C, while advanced ceramics like alumina require temperatures well over 1600°C.

Desired Final Characteristics

The specific temperature chosen within a material's sintering window directly impacts the final component. Higher temperatures generally lead to higher density and strength as more particle boundaries are eliminated.

Conversely, lower temperatures can be used intentionally to create parts with a specific level of porosity or to prevent warping and shrinkage in delicate geometries.

The Role of Temperature in the Sintering Process

Understanding what happens at a microscopic level clarifies why temperature control is so essential. Heat is the catalyst for turning a loose powder into a solid, coherent mass.

Providing Energy for Diffusion

The primary goal of heating is to provide the thermal energy necessary for atomic diffusion. At the correct sintering temperature, atoms from adjacent particles migrate and fill the voids between them.

This process reduces the surface area of the individual particles and forms strong metallurgical or ceramic bonds, resulting in the densification and strengthening of the part.

Furnace Capability vs. Operating Temperature

It's crucial to distinguish between the maximum temperature a furnace can achieve and the temperature required for a specific job. A furnace rated for 1700°C provides the flexibility to process high-temperature ceramics.

However, that same furnace might be run at only 1100°C to sinter a batch of stainless steel components. The furnace's capability must simply exceed the process requirement.

Understanding the Trade-offs

Selecting the wrong temperature is one of the most common failure points in the sintering process. Both overheating and underheating lead to unusable parts.

The Risk of Oversintering

If the temperature is too high or held for too long, you risk crossing the line from sintering to melting. This can cause the part to slump, warp, or lose its intended shape.

Even below the melting point, excessive heat can cause "grain growth," where smaller crystals within the material merge. This can paradoxically make the final part more brittle and prone to failure.

The Problem of Undersintering

If the temperature is too low, diffusion will be insufficient. The bonds between particles will be weak, resulting in a fragile part with high porosity and poor mechanical properties.

The component will lack the density, strength, and integrity required for its intended application and may crumble under stress.

Making the Right Choice for Your Goal

The correct sintering temperature is always a function of your material and your desired outcome. The following principles can guide your decision.

- If your primary focus is maximum density and strength: You will need to operate near the upper end of the material's specified sintering window to maximize atomic diffusion and minimize porosity.

- If your primary focus is creating a porous structure (e.g., for filters): You will use a lower temperature and shorter cycle time to create strong bonds without fully densifying the part.

- If your primary focus is maintaining tight dimensional tolerances: You may need to use a slightly lower temperature to carefully manage the inevitable shrinkage that occurs during densification.

Ultimately, mastering the sintering temperature is the key to controlling the final performance and properties of your component.

Summary Table:

| Key Factor | Typical Temperature Range | Impact on Final Part |

|---|---|---|

| Material Type | 750°C - 1700°C+ | Dictates the sintering window below the melting point. |

| Goal: Max Strength | Higher end of material's range | Increases density and strength by maximizing diffusion. |

| Goal: Controlled Porosity | Lower end of material's range | Creates strong bonds while maintaining intentional voids. |

Achieve precise control over your sintering outcomes. The correct temperature is critical for part density, strength, and performance. KINTEK specializes in high-performance lab furnaces and consumables, providing the reliable equipment and expert support your laboratory needs to master sintering processes. Contact our experts today to discuss your specific material and application requirements.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the difference between firing and sintering? Master the Thermal Process for Stronger Materials

- What is the primary function of a sintering furnace in the powder metallurgy process? Mastering Gradient Materials

- Why are 1500 K furnaces required for rare-earth perovskite synthesis? Overcome Kinetic Barriers for Phase Purity

- What are the technical advantages of using a laboratory vacuum oven for drying MXene nanopowders? | KINTEK

- What role does a high-temperature box furnace play in the densification of high-entropy alloys? Achieve Peak Density.

- What is the critical role of a high-temperature furnace in the synthesis of NASICON? Ensure Pure Crystal Formation.

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- What is the use of a heat treatment oven? Transform Material Properties for Superior Performance