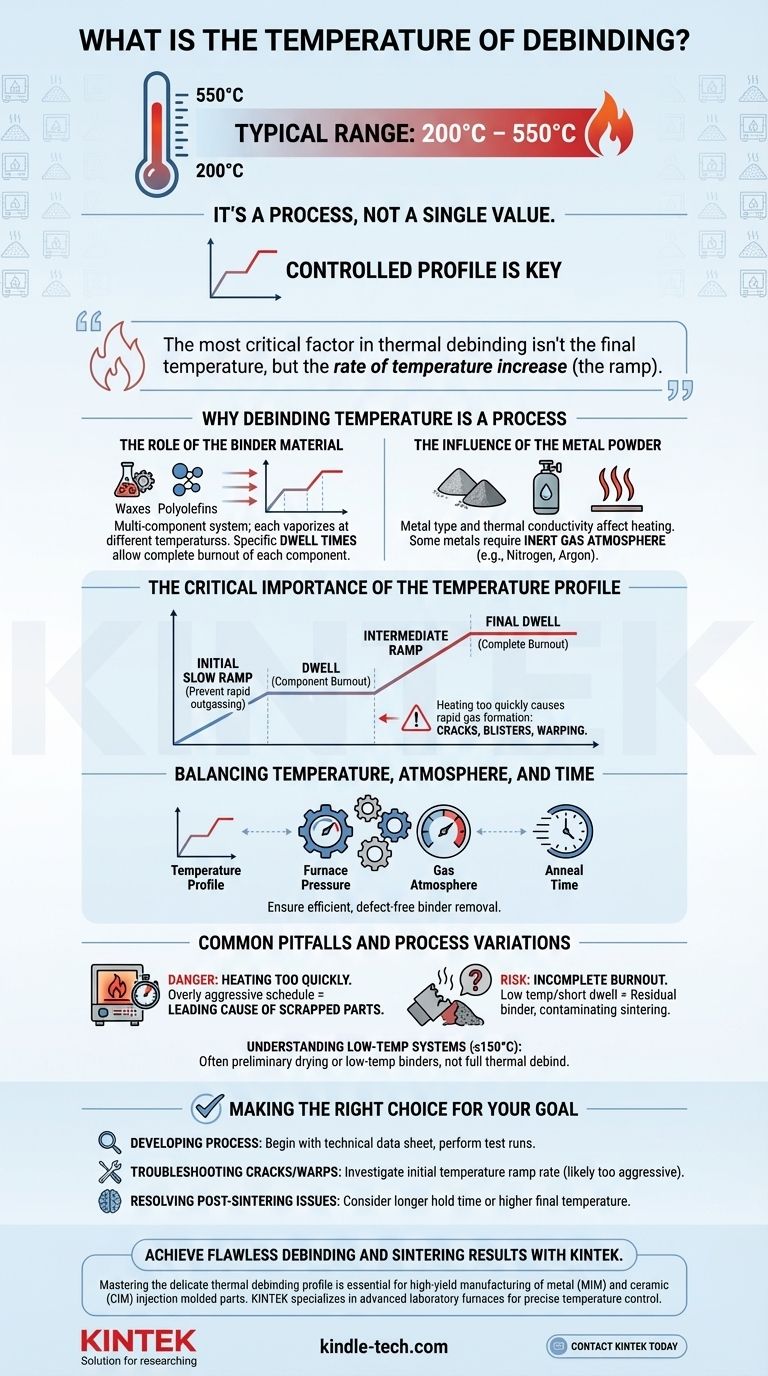

To be precise, the temperature for thermal debinding is not a single value but a carefully controlled profile that typically operates between 200°C and 550°C. The exact temperatures and heating rates are dictated entirely by the specific polymer binder system being used and the type of metal powder in the part. The goal is to remove the binder slowly and completely without creating defects.

The most critical factor in thermal debinding isn't the final temperature, but the rate of temperature increase (the ramp). Heating too quickly causes rapid gas formation that can crack, warp, or otherwise destroy the part before it ever reaches the sintering furnace.

Why Debinding Temperature is a Process, Not a Number

Understanding the "why" behind the temperature range is essential for producing high-quality parts. The entire process is a delicate balance designed to safely evacuate the binder material from the fragile "green" part.

The Role of the Binder Material

The binder is not a single substance but a multi-component system, often a blend of polymers like waxes and polyolefins. Each component vaporizes or thermally decomposes at a different temperature.

The temperature profile must be programmed with specific dwell times at various points. This allows one component of the binder to burn out completely before the temperature ramps up to tackle the next, higher-temperature component.

The Influence of the Metal Powder

The metal powder itself can also influence the process. Some metals are highly susceptible to oxidation, requiring the debinding to occur in a specific inert gas atmosphere (like nitrogen or argon).

Furthermore, the thermal conductivity of the metal powder affects how heat moves through the part, influencing the required ramp rates and hold times to ensure the core is debound at the same rate as the surface.

The Critical Importance of the Temperature Profile

A successful debinding cycle is defined by its temperature profile—the programmed sequence of heating rates and holds. This profile is far more important than any single temperature reading.

The Initial Slow Ramp

The beginning of the cycle is the most hazardous phase. A slow initial ramp is crucial to prevent the lower-temperature binder components from converting to gas too quickly.

This sudden outgassing creates immense internal pressure, leading to the most common debinding defects: cracks, blisters, and part distortion.

Balancing Temperature, Atmosphere, and Time

Temperature does not work in isolation. It must be carefully balanced with other furnace parameters.

Factors like the furnace pressure and the composition of the gas atmosphere must be controlled alongside the temperature profile and anneal time to ensure binder is removed efficiently and without causing unwanted chemical reactions.

Common Pitfalls and Process Variations

Achieving the perfect debind requires avoiding common mistakes and understanding that not all systems are the same.

The Danger of Heating Too Quickly

The primary pitfall is an overly aggressive heating schedule. This is the leading cause of scrapped parts. The desire to shorten cycle times can be costly if it results in cracked or warped components.

The Risk of Incomplete Burnout

Conversely, if the temperature is too low or the dwell times are too short, some of the high-temperature binder components may remain in the part.

This residual binder can contaminate the sintering furnace and, more critically, can outgas violently during the much hotter sintering phase, destroying the part when it is too late to fix.

Understanding Low-Temperature Systems

You may encounter systems that operate at lower temperatures, such as a maximum of 150°C. These are typically not for a full thermal debind.

Instead, they are often used for a preliminary drying step after a solvent debinding process, or for binder systems with extremely low-temperature components. A full thermal debind to remove all organic matter will almost always require temperatures above 200°C.

Making the Right Choice for Your Goal

To define your process, you must first define your priority. The debinding profile must be engineered to match your specific binder, material, and part geometry.

- If your primary focus is developing a new process: Begin with the technical data sheet from your binder or feedstock supplier and perform test runs on non-critical parts.

- If your primary focus is troubleshooting cracks or warps: Immediately investigate your initial temperature ramp rate; it is almost certainly too aggressive for the part's geometry or thickness.

- If your primary focus is resolving post-sintering issues: Consider the possibility of incomplete binder burnout, which may require a longer hold time or a slightly higher final temperature in your debinding profile.

Ultimately, mastering the thermal debinding profile is the key to unlocking consistent, high-yield advanced manufacturing.

Summary Table:

| Key Aspect | Description |

|---|---|

| Typical Temperature Range | 200°C to 550°C |

| Primary Goal | Remove binder completely without creating defects (cracks, warping). |

| Most Critical Factor | The rate of temperature increase (ramp), not the final temperature. |

| Key Influences | Binder system composition and metal/ceramic powder type. |

| Common Pitfall | Heating too quickly, causing rapid gas formation and part failure. |

Achieve flawless debinding and sintering results with KINTEK.

Mastering the delicate thermal debinding profile is essential for high-yield manufacturing of metal (MIM) and ceramic (CIM) injection molded parts. KINTEK specializes in advanced laboratory furnaces and consumables designed for precise temperature control and uniform heating, ensuring your binder is removed safely and completely.

Our experts can help you select the right equipment and optimize your process to avoid common defects like cracking and warping. Let us provide the reliable thermal solutions your laboratory needs for consistent, high-quality results.

Contact KINTEK today to discuss your specific debinding and sintering requirements.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature muffle furnace work? Achieve Contaminant-Free, Uniform Heating

- How does heat affect strength materials? The Science of Thermal Degradation Explained

- What is done by ashing in muffle furnace? A Guide to Precise Inorganic Content Analysis

- What are the main components of a high-temperature muffle furnace? A Guide to the Core Systems

- What is the primary characteristic of a muffle furnace? Unlock Pure, Contamination-Free Heating