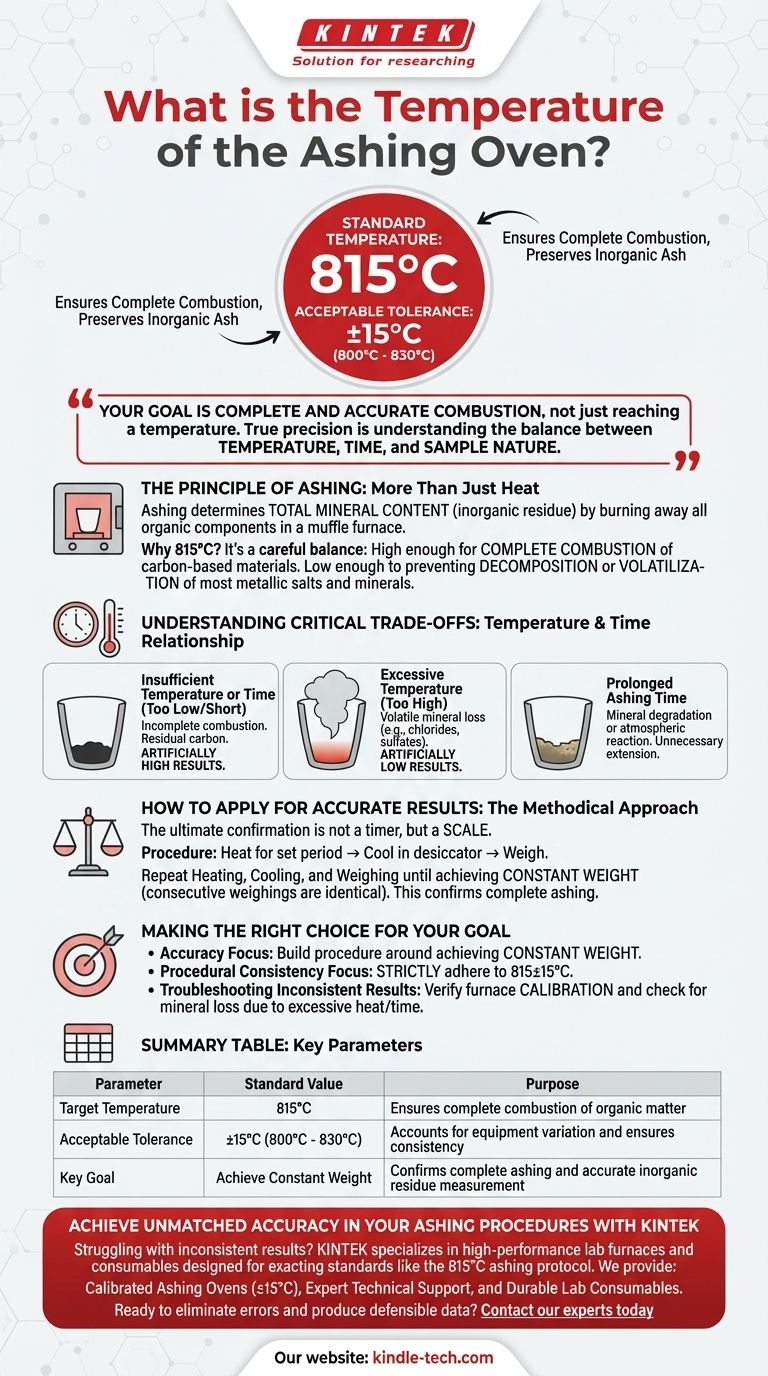

The standard temperature for an ashing oven is set to 815°C with an acceptable tolerance of ±15°C. This specific temperature is a critical parameter designed to ensure the complete combustion of organic matter from a sample, leaving behind only the inorganic ash for measurement.

Your goal is not just to reach a specific temperature, but to achieve complete and accurate combustion. True precision comes from understanding the balance between temperature, time, and the chemical nature of your sample.

The Principle of Ashing: More Than Just Heat

Ashing is a fundamental analytical technique used to determine the total mineral content, or inorganic residue, within a sample. The process involves high-temperature combustion in a muffle furnace to burn away all organic components.

Why 815°C is the Standard

This temperature is not arbitrary. It represents a carefully determined balance point. It is high enough to guarantee the complete combustion of carbon-based organic materials into carbon dioxide and water vapor.

At the same time, this temperature is generally low enough to prevent the decomposition or volatilization of most common metallic salts and minerals that constitute the ash.

The Role of the ±15°C Tolerance

The ±15°C tolerance (800°C to 830°C) is a practical window. It accounts for minor variations in furnace calibration and performance, ensuring that results are consistent and repeatable across different laboratories and equipment. Adhering to this range is essential for standardized testing methods.

Understanding the Critical Trade-offs

Simply setting the oven to 815°C does not guarantee an accurate result. The relationship between temperature and time is crucial, and improper procedure can introduce significant errors.

The Risk of Insufficient Temperature or Time

If the temperature is too low or the ashing time is too short, combustion will be incomplete. This leaves residual carbon in the sample, which is incorrectly weighed as ash, leading to artificially high results.

The Danger of Excessive Temperature

Exceeding the recommended temperature range is a significant risk. Many mineral salts, particularly chlorides and sulfates, can become volatile at very high temperatures. This causes them to vaporize and be lost, leading to an underestimation of the true ash content and artificially low results.

The Problem with Prolonged Ashing Time

Even at the correct temperature, extending the ashing time unnecessarily is unfavorable. Over long periods, some minerals can slowly degrade or react with atmospheric gases. The goal is to ash the sample for the minimum time required to achieve a constant weight, not for an arbitrary duration.

How to Apply This for Accurate Results

Achieving reliable data requires a methodical approach that goes beyond setting the temperature. The ultimate confirmation of complete ashing is not a timer, but a scale.

Verifying Complete Ashing

The correct procedure involves heating the sample for a set period, then moving it to a desiccator to cool completely without absorbing atmospheric moisture. The sample is then weighed.

This process of heating, cooling, and weighing must be repeated. Ashing is only considered complete when two consecutive weighings show a constant weight, indicating that all combustible material has been removed.

Making the Right Choice for Your Goal

Use these principles to guide your laboratory procedure and troubleshoot your results.

- If your primary focus is accuracy: Your procedure must be built around achieving a constant weight, not just adhering to a fixed time at temperature.

- If your primary focus is procedural consistency: Strictly adhere to the 815±15°C range as defined by your official method (e.g., AOAC, ASTM) to ensure valid comparisons.

- If you are troubleshooting inconsistent results: First, verify your furnace's temperature calibration, then review your procedure to ensure you are not losing volatile minerals due to excessive heat or time.

Mastering these variables is the key to producing reliable and defensible analytical data.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Target Temperature | 815°C | Ensures complete combustion of organic matter |

| Acceptable Tolerance | ±15°C (800°C - 830°C) | Accounts for equipment variation and ensures consistency |

| Key Goal | Achieve constant weight | Confirms complete ashing and accurate inorganic residue measurement |

Achieve Unmatched Accuracy in Your Ashing Procedures with KINTEK

Struggling with inconsistent ash content results? The precision of your analysis depends on reliable equipment and expert knowledge. KINTEK specializes in high-performance lab furnaces and consumables designed for exacting standards like the 815°C ashing protocol.

We provide:

- Calibrated Ashing Ovens that maintain precise temperature control within ±15°C

- Expert Technical Support to help you optimize procedures for constant weight verification

- Durable Lab Consumables that withstand high-temperature processes without contamination

Ready to eliminate errors and produce defensible analytical data? Contact our experts today to find the perfect ashing solution for your laboratory's specific needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is a high-temperature sintering furnace necessary for ceramic MFC separators? Optimize Your Proton Exchange

- What is the role of high-temperature muffle furnaces in the synthesis of NASICON-structured LATP ceramic powder?

- What role does a high-temperature sintering furnace play in the crystalline phase formation of Li4Ti5O12?

- What is the function of a muffle furnace in forming Ag/Ce-Mn solid solutions? Optimize Your Catalyst Synthesis

- Why are 1500 K furnaces required for rare-earth perovskite synthesis? Overcome Kinetic Barriers for Phase Purity

- How do you use the muffle furnace? Master Safe and Precise High-Temperature Processing

- What is the function of muffle? A Guide to Clean, Uniform Heating & Process Control

- Why is it necessary to perform heat treatment in a muffle furnace after TiO2 nanotube synthesis? Unlock Anatase Power