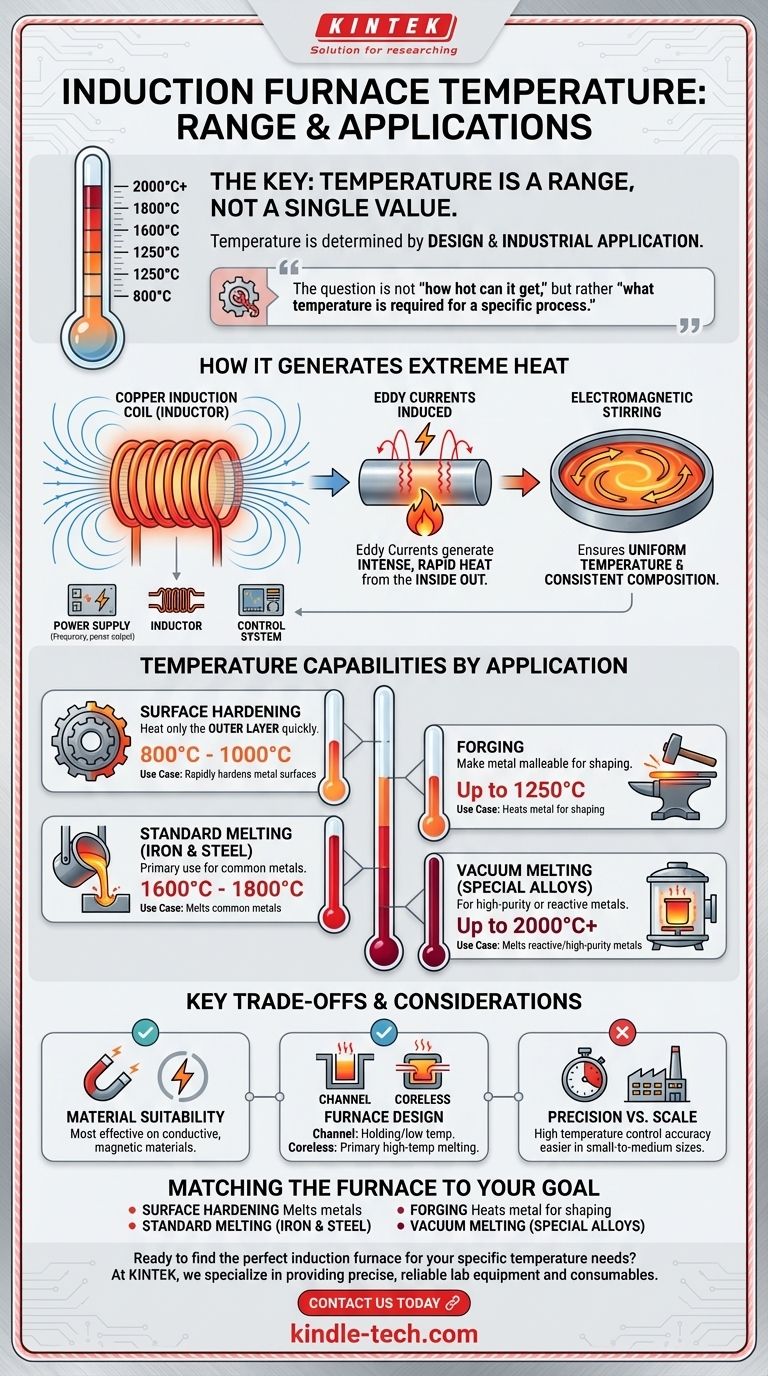

The temperature of an induction furnace is not a single value but a range determined by its design and industrial application. Depending on the task, operating temperatures can span from 800°C for surface hardening to over 2000°C (3632°F) for melting specialized alloys in a vacuum. The most common melting applications, such as for iron and steel, typically require temperatures between 1600°C and 1800°C.

The key takeaway is that an induction furnace's temperature capability is a direct function of its intended purpose. The question is not "how hot can it get," but rather "what temperature is required for a specific process like forging, melting, or surface treatment."

How Induction Furnaces Generate Extreme Heat

An induction furnace doesn't use external heating elements like a conventional oven. Instead, it generates heat directly within the material itself, leading to high efficiency and precise control.

The Principle of Induction

An induction furnace uses a powerful alternating magnetic field generated by a copper coil.

When a conductive material (like metal) is placed inside this field, it induces powerful electrical currents, known as eddy currents, within the metal.

The material's natural resistance to the flow of these eddy currents generates intense and rapid heat, causing it to heat up and eventually melt from the inside out.

The Advantage of Electromagnetic Stirring

The same magnetic field that creates the heat also causes the molten metal to stir.

This electromagnetic stirring action is a significant advantage, as it ensures a highly uniform temperature and consistent chemical composition throughout the entire molten bath.

Core System Components

The primary components that work together to achieve these temperatures are the power supply, a copper induction coil (inductor), and a control system. The power supply's frequency and power output are critical factors in determining the heating efficiency and final temperature.

Temperature Capabilities by Application

The required temperature varies significantly based on the industrial process. Each type of furnace is engineered to operate efficiently within a specific temperature range.

Surface Hardening

For processes like surface hardening, the goal is to heat only the outer layer of a metal part very quickly.

Induction systems can heat a workpiece's surface to 800°C - 1000°C in just a few seconds, hardening the surface without affecting the core's properties.

Forging

Heating metal to make it malleable for forging requires lower temperatures than melting.

A typical induction furnace designed for forging applications will operate at temperatures up to 1250°C.

Standard Melting (Iron & Steel)

Melting common metals like cast iron and steel alloys is a primary use for induction furnaces.

These furnaces are designed to reach and sustain temperatures up to 1650°C, with some capable of exceeding 1800°C depending on the charge materials and coil coupling.

Specialized and Vacuum Melting

For high-purity metals or reactive alloys, melting is performed in a vacuum to prevent contamination.

Vacuum induction melting (VIM) furnaces are specialized units that can achieve the highest temperatures, often reaching 2000°C.

Understanding the Key Trade-offs

While powerful, induction furnaces are not a universal solution. Their performance and suitability depend on several factors.

Material Suitability

Induction heating is most effective on electrically conductive and, ideally, magnetic materials. The efficiency of heating depends on the specific electrical and magnetic properties of the metal being processed.

Furnace Design

Different furnace designs exist for different tasks. A channel furnace, for instance, is often used for holding molten metal at temperature or for melting lower-temperature alloys like aluminum. A coreless induction furnace is more commonly used for primary melting of high-temperature alloys like steel.

Precision vs. Scale

A major advantage of induction is its high temperature control accuracy and the small temperature difference between the material's core and surface. This precision is easiest to manage in small-to-medium-sized furnaces. Scaling up to very large volumes can introduce new complexities.

Matching the Furnace to Your Goal

To select the right equipment, you must first define your thermal processing objective.

- If your primary focus is surface treatment or case hardening: You need a high-frequency system designed for rapid, localized heating up to 1000°C.

- If your primary focus is forging steel: A furnace optimized for a consistent bulk temperature of around 1250°C is the correct tool.

- If your primary focus is melting iron, steel, or copper alloys: Your system must be robust enough to operate continuously in the 1600°C to 1800°C range.

- If your primary focus is melting reactive metals or superalloys: A specialized vacuum induction furnace capable of reaching 2000°C is required for purity and performance.

Ultimately, the temperature of an induction furnace is a precisely engineered variable, tailored to meet the demands of a specific industrial task.

Summary Table:

| Application | Typical Temperature Range | Key Use Case |

|---|---|---|

| Surface Hardening | 800°C - 1000°C | Rapidly hardens metal surfaces |

| Forging | Up to 1250°C | Heats metal for shaping |

| Standard Melting (Iron/Steel) | 1600°C - 1800°C | Melts common metals |

| Vacuum Melting (Special Alloys) | Up to 2000°C+ | Melts reactive/high-purity metals |

Ready to find the perfect induction furnace for your specific temperature needs? At KINTEK, we specialize in providing precise, reliable lab equipment and consumables for all your thermal processing requirements. Whether you're hardening surfaces, forging metals, or melting specialized alloys, our experts will help you select the ideal furnace for your application. Contact us today to discuss your project and discover how KINTEK can enhance your laboratory's efficiency and results!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control