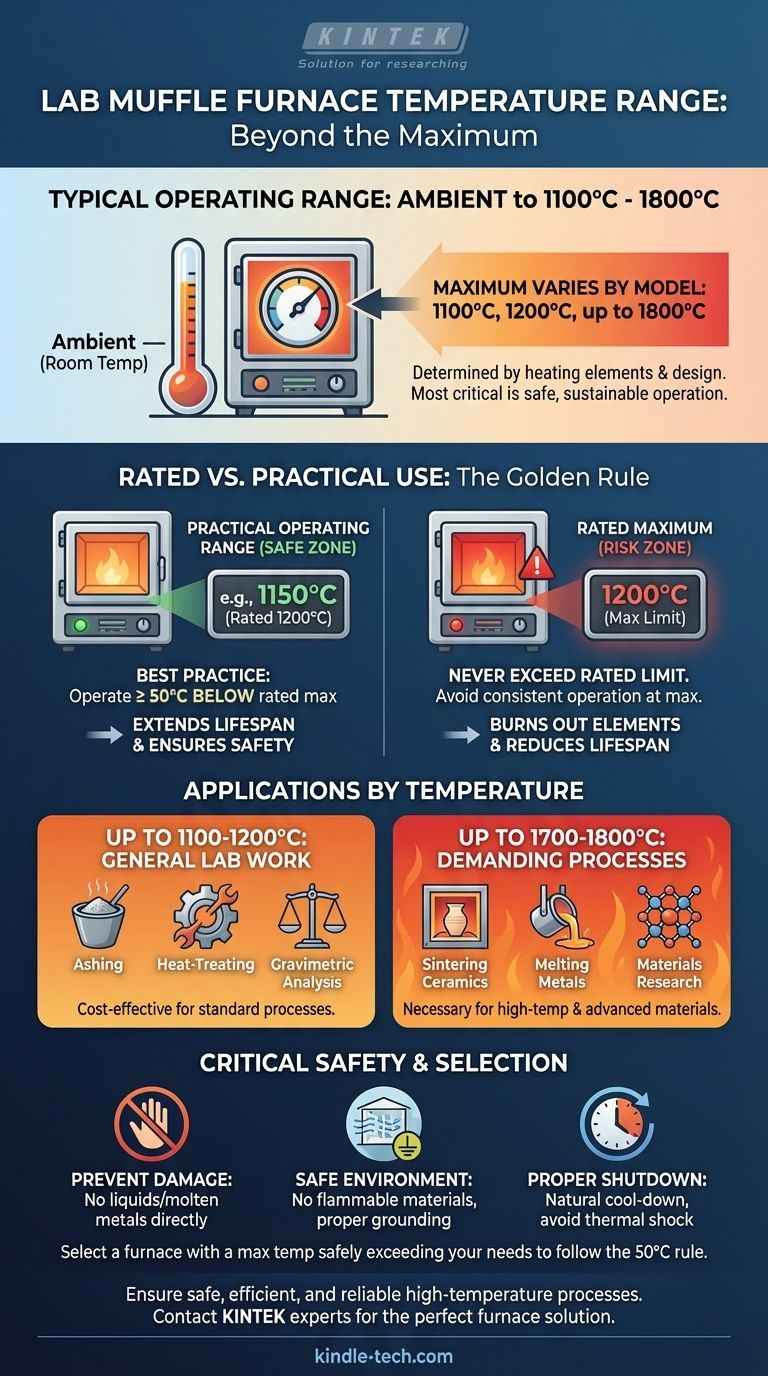

In short, a laboratory muffle furnace typically operates from ambient room temperature up to a maximum that falls between 1100°C and 1800°C (2012°F to 3272°F). The exact maximum temperature is determined entirely by the specific model, its heating elements, and its intended application.

The most critical factor is not the furnace's absolute maximum temperature, but its safe and sustainable operating range. Operating a furnace consistently at its rated limit significantly shortens its lifespan and compromises safety.

Defining the Operating Temperature Range

A muffle furnace is designed for high-temperature applications, but its capabilities are defined by key thermal boundaries. Understanding these is essential for proper use and purchasing decisions.

Minimum and Maximum Temperatures

The furnace begins heating from the ambient temperature of the laboratory. Its upper limit varies significantly by design, with common maximums around 1100°C, 1200°C, and up to 1800°C for specialized models.

Why Do Maximum Temperatures Vary?

The primary differentiator is the type of electric heating element used in the furnace's construction. Different materials are required to reliably and safely generate and withstand higher heat levels, which directly impacts the furnace's cost and application scope.

The Impact on Applications

Furnaces with maximum temperatures around 1100-1200°C are common for general laboratory work like ashing, heat-treating, and gravimetric analysis. Models reaching 1700-1800°C are necessary for more demanding processes, such as melting metals, sintering advanced ceramics, or materials science research.

Understanding the Trade-offs: Rated vs. Practical Use

The temperature written on the specification sheet is a limit, not a target. For safety and equipment longevity, the practical operating temperature is always lower than the rated maximum.

Never Exceed the Rated Temperature

Pushing the furnace beyond its maximum rated temperature is the fastest way to burn out and destroy the electric heating elements. This is a strict operational limit that must always be respected.

The "50°C Below Max" Guideline

For consistent, long-term use, it is best practice to operate the furnace at least 50°C below its stated maximum temperature. This simple measure dramatically reduces stress on the heating elements and can significantly extend the furnace's operational life.

Environmental Limits

The furnace's performance and safety also depend on its environment. The electronic controller must be kept within its specified ambient temperature range, typically 0-40°C (32-104°F), to ensure accurate temperature regulation.

Critical Safety Protocols for High-Temperature Work

Operating a muffle furnace requires strict adherence to safety procedures to protect both the user and the equipment.

Preventing Furnace Damage

Never pour liquids or molten metals directly onto the furnace hearth. If heating volatile substances, ensure they are in a properly sealed container to prevent gases from damaging the heating elements and insulation.

Ensuring a Safe Environment

The furnace must be operated in a location free of flammable materials, explosive gases, and conductive dust. Proper electrical grounding is mandatory.

Proper Shutdown Procedure

After completing your work, always turn off the main power and allow the furnace to cool down naturally. Removing items or forcing a cool-down can cause thermal shock to both your sample and the furnace chamber.

Making the Right Choice for Your Application

Selecting a furnace requires looking beyond the maximum temperature and matching the specifications to your actual needs.

- If your primary focus is standard ashing or general heat treating: A furnace with a maximum rated temperature of 1100°C or 1200°C will be sufficient and cost-effective.

- If your primary focus is materials research or metal casting: You must invest in a specialized high-temperature furnace rated for 1700°C to 1800°C.

- If your primary focus is equipment longevity and reliability: Always choose a furnace with a maximum temperature that safely exceeds your highest required process temperature, allowing you to follow the "50°C below max" rule.

By understanding the difference between a rated limit and a practical operating range, you can ensure your equipment performs safely and reliably for years to come.

Summary Table:

| Temperature Range | Common Applications | Key Consideration |

|---|---|---|

| Up to 1100-1200°C | Ashing, Heat-Treating, Gravimetric Analysis | Cost-effective for general lab work |

| Up to 1700-1800°C | Sintering Ceramics, Melting Metals, Materials Research | Necessary for high-temperature processes |

| Practical Use (50°C below max) | All Applications | Extends furnace lifespan and ensures safety |

Ensure your lab's high-temperature processes are safe, efficient, and reliable. The right muffle furnace is critical for achieving accurate results in ashing, heat-treating, or advanced materials research. KINTEK specializes in lab equipment and consumables, providing durable muffle furnaces designed for your specific temperature requirements and application goals.

Contact our experts today to discuss your needs and find the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How long is the calcination process? Optimize Your Process Time for Maximum Efficiency

- How do you choose calcination temperature? A Guide to Optimizing Material Properties

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%

- Do different liquids melt at different rates? Unlock the Science of Melting Points and Material Properties

- How do the properties of materials change with the heat treatment? Tailor Hardness, Strength, and Ductility