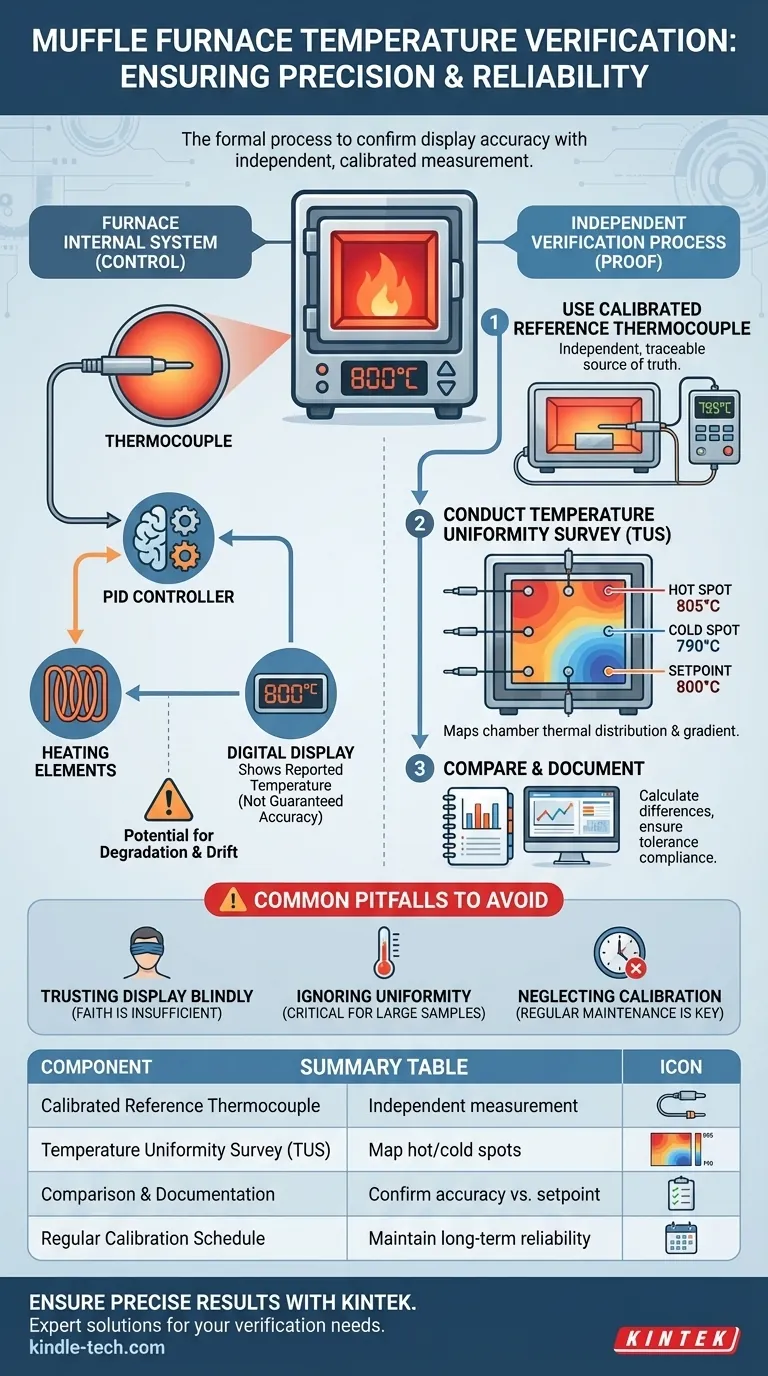

To be clear, temperature verification in a muffle furnace is the formal process of confirming that the temperature shown on the control display accurately reflects the true temperature inside the heating chamber. This is not the same as setting the temperature; it is a quality assurance step performed using an independent, calibrated measuring device to ensure the furnace's internal control system is performing correctly.

A furnace's built-in system is designed to control the temperature, but independent verification is required to prove that control is accurate. This distinction is critical for any process where precise thermal conditions are essential for reliable and repeatable results.

The Furnace's Internal Control System

To understand verification, you must first understand how the furnace manages its own temperature. The system is a feedback loop consisting of three core components.

The Role of the Thermocouple

A thermocouple is a sensor placed inside the furnace chamber. It measures the ambient temperature and sends an electrical signal back to the main controller.

This signal is the sole source of temperature data for the furnace's automated system.

The Function of the Controller

The furnace is managed by an intelligent temperature controller, often using a PID (Proportional-Integral-Derivative) algorithm. This controller acts as the brain of the operation.

It compares the real-time temperature signal from the thermocouple to the user-defined setpoint. It then calculates and adjusts the amount of power sent to the heating elements to either raise or lower the temperature as needed.

The Display vs. Reality

The digital display on the control panel shows the temperature being reported by the internal thermocouple. While this indicates the system is operational, it does not, by itself, guarantee accuracy.

The internal thermocouple can degrade, drift over time, or be positioned in a way that doesn't represent the true temperature where your material is placed.

The Process of Independent Verification

True verification requires an external system to challenge the furnace's internal reading. This process moves from assumption to certainty.

Step 1: Use a Calibrated Reference Thermocouple

The standard method involves placing one or more independent, calibrated reference thermocouples into the furnace chamber alongside the material or in its place.

This reference system must have its own separate, calibrated readout device. Its accuracy should be traceable to a national standard to serve as a reliable source of truth.

Step 2: Conduct a Temperature Uniformity Survey (TUS)

A furnace chamber rarely has a perfectly uniform temperature. There can be hot and cold spots.

A Temperature Uniformity Survey (TUS) involves placing multiple reference thermocouples at different locations within the usable chamber volume. This survey maps the temperature distribution and identifies the hottest and coldest points, ensuring the entire workspace is within the required tolerance.

Step 3: Compare and Document

With the furnace at a stable setpoint, you record the reading from the furnace's display and the readings from all reference thermocouples.

The difference between the furnace's setpoint and the reference measurements determines if the furnace is operating within its specified accuracy. This data is documented for quality control and auditing purposes.

Common Pitfalls to Avoid

Achieving accurate thermal processing requires avoiding common but critical mistakes.

Pitfall 1: Trusting the Display Blindly

The most frequent error is assuming the furnace display is always correct. Without periodic, independent verification, you are operating on faith, which is insufficient for any critical scientific or manufacturing process.

Pitfall 2: Ignoring Temperature Uniformity

Verifying the temperature at a single point may not be enough. If your sample is large or your process is sensitive, a significant temperature gradient across the chamber could compromise your results, even if the furnace's single thermocouple reads correctly.

Pitfall 3: Neglecting Calibration Schedules

Verification is not a one-time event. Both the furnace's internal control system and the external verification equipment require regular calibration and maintenance to counteract drift and ensure long-term accuracy.

Making the Right Choice for Your Goal

Your approach to verification should match the demands of your application.

- If your primary focus is general, non-critical heating: Simply ensuring the furnace heats to the setpoint and holds a stable temperature may be sufficient for your needs.

- If your primary focus is quality control, material science, or meeting standards: A formal verification with a calibrated, external system and a Temperature Uniformity Survey is non-negotiable.

- If your primary focus is troubleshooting a failed process: Independent temperature verification should be the first diagnostic step to confirm or eliminate the furnace as the source of the problem.

By moving from simple operation to rigorous verification, you gain complete control over the thermal integrity of your process.

Summary Table:

| Key Verification Component | Purpose |

|---|---|

| Calibrated Reference Thermocouple | Provides independent temperature measurement |

| Temperature Uniformity Survey (TUS) | Maps hot/cold spots across the chamber |

| Comparison & Documentation | Confirms furnace accuracy vs. setpoint |

| Regular Calibration Schedule | Maintains long-term measurement reliability |

Ensure your muffle furnace delivers precise, reliable results every time. KINTEK specializes in laboratory equipment and consumables, providing the tools and expertise needed for accurate temperature verification. Whether you're in quality control, material science, or general lab work, our solutions help you maintain process integrity and meet industry standards. Contact our experts today to discuss your specific furnace verification needs and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of a muffle furnace? Achieve Pure, Contamination-Free High-Temperature Heating

- How do you maintain a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- What is the difference between a lab oven and a muffle furnace? A Guide to Temperature Applications

- What are the specs of a muffle furnace? A Guide to Key Features & Selection

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Lab's Needs