At its core, the theory of spark plasma sintering (SPS) describes a material consolidation process that uses a pulsed direct electric current and uniaxial pressure to achieve rapid densification. Unlike conventional sintering that relies on slow, external heating, SPS generates heat directly within the conductive die and the material itself, while also creating localized plasma between powder particles to dramatically accelerate the bonding process.

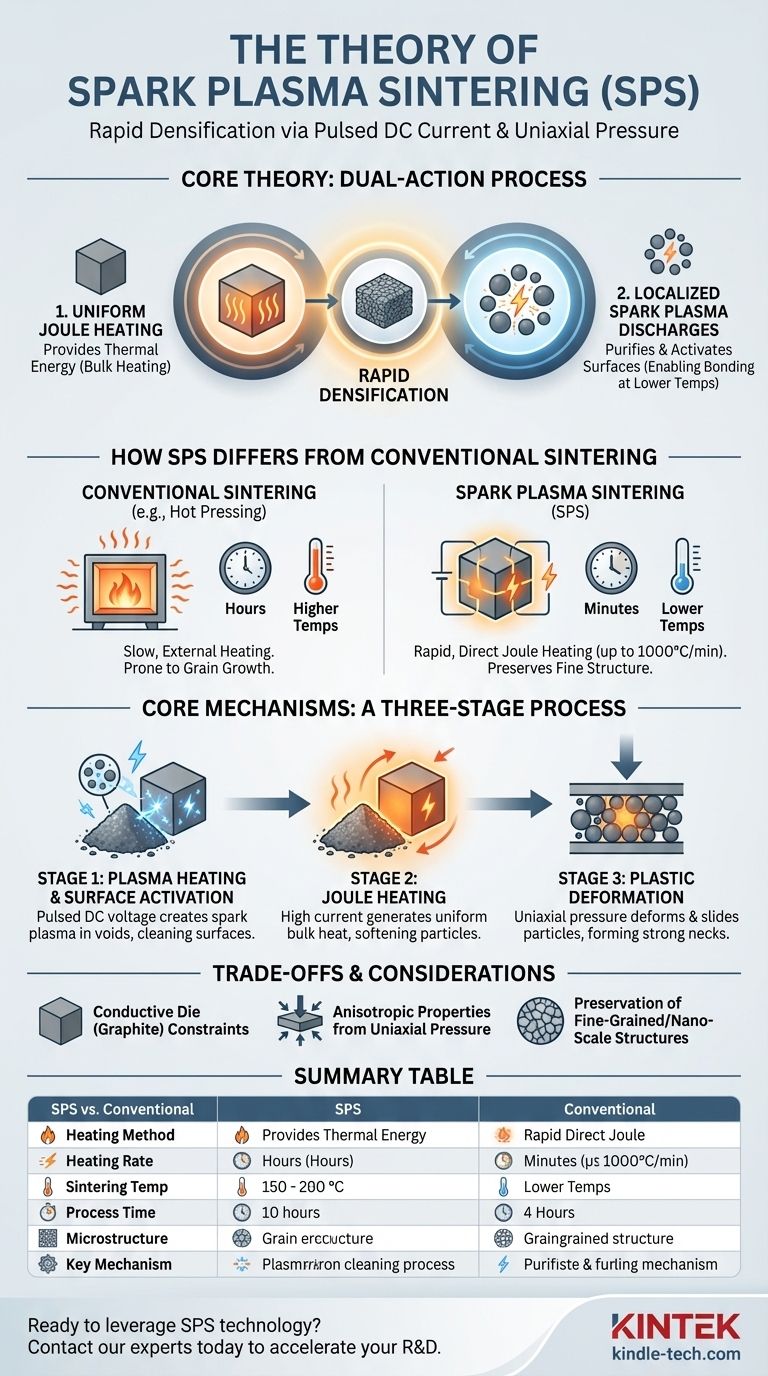

The central theory of SPS is not merely about rapid heating. It is a dual-action process where uniform Joule heating provides the thermal energy for densification, while localized spark plasma discharges between particles purify and activate their surfaces, enabling superior bonding at lower temperatures and in less time.

How SPS Differs from Conventional Sintering

To understand the theory of SPS, it is essential to contrast it with traditional methods like hot pressing, which also use heat and pressure. The key difference lies in the method and speed of energy delivery.

The Source of Heat

In conventional sintering or hot pressing, heat is generated by an external heating element and radiates inward to the sample. This is a relatively slow and often inefficient process.

SPS, also known as a field-assisted sintering technique (FAST), passes a powerful electric current directly through the graphite die and, if the material is conductive, the powder compact itself. This generates instantaneous, uniform Joule heat throughout the system.

The Speed and Temperature

The direct heating method of SPS allows for extremely rapid heating rates, sometimes as high as 1000°C/min. This shortens the entire sintering process from many hours to just a few minutes.

Consequently, densification is achieved at significantly lower overall temperatures—often several hundred degrees Celsius below what is required for conventional methods.

The Core Mechanisms: A Three-Stage Process

The unique effects of SPS can be understood as a sequence of three overlapping physical stages that work in concert to consolidate the material.

Stage 1: Plasma Heating and Surface Activation

When the pulsed DC voltage is first applied, a discharge occurs in the voids between individual powder particles. This creates momentary, localized pockets of spark plasma.

These sparks can reach temperatures of several thousand degrees Celsius. This intense, localized heat purifies the particle surfaces by vaporizing adsorbed gases and other contaminants. This "cleaning" effect activates the surfaces, making them highly receptive to bonding.

Stage 2: Joule Heating

Simultaneously, the high electric current flowing through the conductive die and the powder compact generates immense and uniform Joule heat.

This is the primary mechanism for raising the bulk temperature of the material. It softens the particles, preparing them for consolidation under the applied mechanical pressure.

Stage 3: Plastic Deformation

With the particle surfaces purified and the bulk material heated, an external, uniaxial pressure is applied. This mechanical force causes the softened particles to deform and slide against one another.

This action eliminates the voids between particles and forces the activated surfaces into intimate contact, forming strong metallurgical "necks" that lead to a dense final product.

Understanding the Trade-offs and Considerations

While powerful, the theory behind SPS also implies several operational constraints that are critical to understand.

Material and Geometric Constraints

The process relies on a conductive die, which is almost always graphite. This places practical limits on the size and complexity of the shapes that can be produced. Furthermore, the powder itself must be able to withstand the direct effects of the electric current.

Uniaxial Pressure Effects

Because pressure is applied from a single direction (uniaxially), the resulting material can have anisotropic properties, meaning its mechanical characteristics may differ depending on the direction of measurement.

Preservation of Microstructure

One of the most significant advantages derived from the theory is the preservation of fine-grained or nano-scale structures. The extremely short sintering time and lower temperatures prevent the grain growth that plagues conventional, high-temperature methods. This is critical for creating materials with enhanced mechanical properties.

Making the Right Choice for Your Goal

Applying the theory of SPS depends entirely on your end goal for the material.

- If your primary focus is speed and throughput: SPS is an unparalleled technology for rapidly producing dense material samples in a laboratory or small-scale production setting.

- If your primary focus is preserving nano-scale structures: The combination of low temperature and short holding time makes SPS the ideal choice for consolidating advanced, nanostructured powders without destroying their unique properties.

- If your primary focus is material purity and bonding: The unique plasma-cleaning effect offers an in-situ surface purification mechanism that can lead to superior bonding interfaces compared to other methods.

Ultimately, understanding the theory of SPS allows you to leverage its unique combination of thermal, electrical, and mechanical forces to produce advanced materials that are simply not achievable through conventional methods.

Summary Table:

| Aspect | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Method | Direct Joule heating within die/powder | External, radiant heating |

| Heating Rate | Very high (up to 1000°C/min) | Slow |

| Sintering Temperature | Lower | Higher |

| Process Time | Minutes | Hours |

| Microstructure | Preserves fine/nano grains | Prone to grain growth |

| Key Mechanism | Spark plasma surface activation + Joule heating | Thermal diffusion |

Ready to leverage SPS technology for your advanced materials?

KINTEK specializes in providing state-of-the-art lab equipment and consumables for materials research and development. Our expertise in sintering technologies can help you achieve rapid densification, preserve nanoscale structures, and enhance material purity for superior results.

Contact our experts today to discuss how our solutions can accelerate your R&D and production goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Graphite Vacuum Continuous Graphitization Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology