At its core, vacuum coating is a high-precision process for applying an extremely thin yet durable layer of material onto a surface. This technology is used across countless industries—from aerospace and automotive to medical and electronics—to fundamentally change the properties of a substrate, granting it new capabilities like enhanced durability, electrical conductivity, or specific optical behaviors.

The purpose of vacuum coating is not simply to cover an object, but to engineer its surface at a microscopic level. By operating in a vacuum, the process deposits an ultra-pure, uniform, and high-adhesion film that would be impossible to create in normal atmospheric conditions.

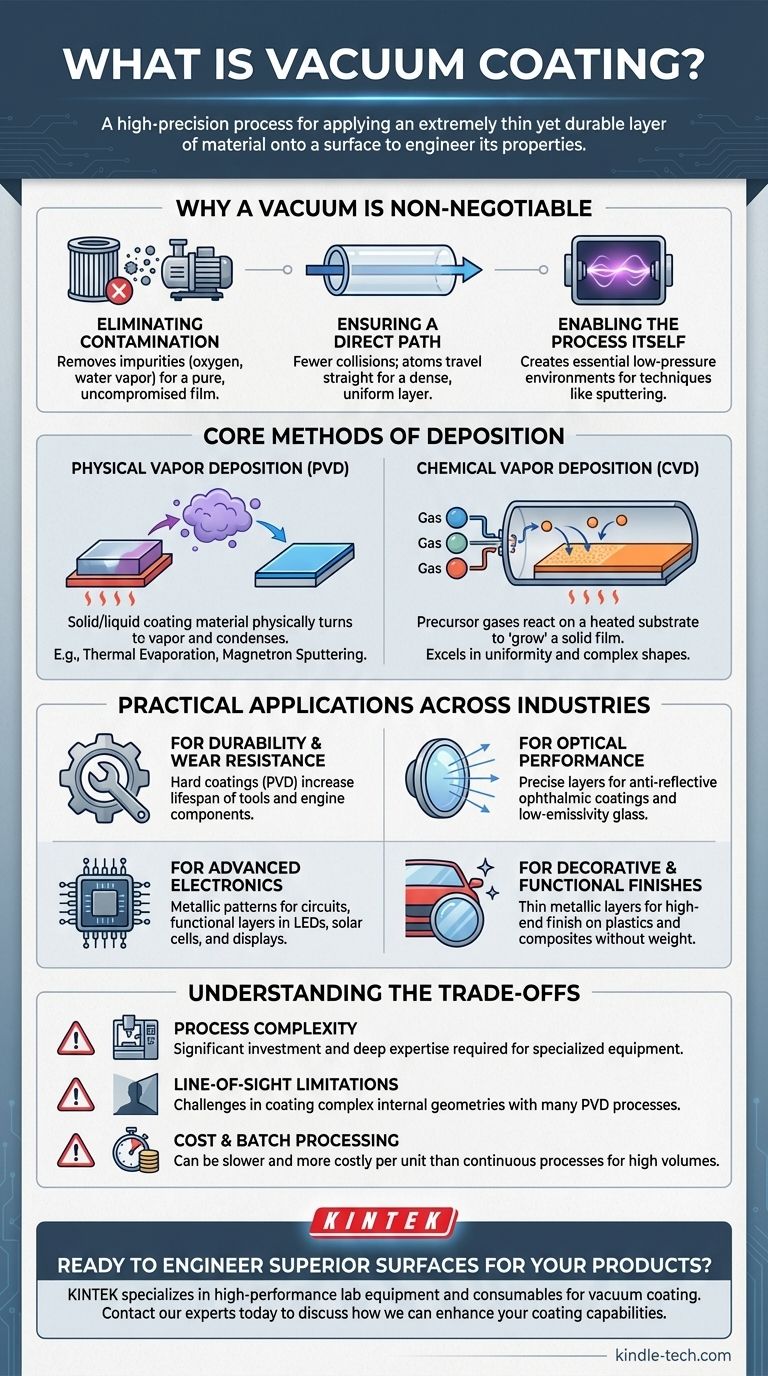

Why a Vacuum is Non-Negotiable

To understand the use of vacuum coating, you must first understand why the vacuum itself is critical. The sub-atmospheric pressure environment solves three fundamental problems that would otherwise ruin the coating process.

Eliminating Contamination

Air is filled with particles like oxygen, nitrogen, and water vapor. If present during deposition, these particles would react with the coating material, creating impurities and compromising the integrity of the film. A vacuum removes these contaminants, ensuring a pure coating.

Ensuring a Direct Path

In a vacuum, there are very few air molecules for the coating particles to collide with. This allows atoms or molecules from the vapor source to travel in a straight line to the substrate, resulting in a dense, uniform, and strongly bonded layer.

Enabling the Process Itself

Many coating techniques, particularly a method called sputtering, require a controlled, low-pressure environment to create and sustain a plasma. This plasma is essential for dislodging atoms from the coating material, and it can only exist under vacuum conditions.

The Core Methods of Deposition

While there are many specific techniques, most fall into two primary families: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

Physical Vapor Deposition (PVD)

PVD is a process where a solid or liquid coating material is physically turned into a vapor, which then travels through the vacuum chamber and condenses on the substrate as a thin film.

Think of it like steam from a boiling kettle condensing on a cold window, but on an atomic scale. Common PVD methods include thermal evaporation and magnetron sputtering.

Chemical Vapor Deposition (CVD)

CVD involves introducing precursor gases into the vacuum chamber. These gases undergo a chemical reaction on a heated substrate, decomposing to "grow" a solid film on the surface.

This method is less like condensation and more like building a structure atom-by-atom. It excels at creating exceptionally uniform layers over large areas and complex shapes.

Practical Applications Across Industries

The versatility of vacuum coating allows it to solve problems in nearly every advanced manufacturing sector.

For Durability and Wear Resistance

Hard coatings, typically applied with PVD, can dramatically increase the lifespan of tools and engine components by protecting them from friction and abrasion.

For Optical Performance

Layers just a few atoms thick can be precisely applied to control how light interacts with a surface. This is used for anti-reflective ophthalmic coatings on eyeglasses and creating low-emissivity glass that improves building insulation.

For Advanced Electronics

Vacuum coating is fundamental to modern electronics. It is used to deposit the metallic patterns that form circuits in microchips, create the functional layers in LEDs and solar cells, and manufacture the thin-film transistors used in flexible displays.

For Decorative and Functional Finishes

The process can apply a thin, durable metallic layer to materials like plastic and carbon fiber composites, providing a high-end finish for automotive parts and consumer goods without adding significant weight.

Understanding the Trade-offs

While powerful, vacuum coating is not a universal solution. It involves specific limitations that make it suitable for some applications but not others.

Process Complexity

Vacuum coating requires significant capital investment in specialized equipment, including vacuum chambers and multiple types of pumps. It is a technically demanding process requiring deep expertise to control.

Line-of-Sight Limitations

Many PVD processes are "line-of-sight," meaning they can only coat surfaces directly exposed to the vapor source. This makes it challenging to achieve uniform coverage on components with complex internal geometries.

Cost and Batch Processing

Vacuum coating is typically a batch process, where a set number of parts are loaded, coated, and then unloaded. This can be slower and more costly per unit than continuous processes like electroplating for certain high-volume applications.

How to Apply This to Your Goal

The ideal vacuum coating strategy depends entirely on the desired outcome for your product.

- If your primary focus is extreme hardness and wear resistance: PVD techniques like sputtering are often the superior choice for tools and industrial components.

- If your primary focus is creating highly uniform layers over complex shapes: CVD is often preferred for critical applications like semiconductor manufacturing.

- If your primary focus is optical performance: Precisely controlled PVD methods are used to create multi-layer films for lenses, mirrors, and energy-efficient glass.

- If your primary focus is a cost-effective decorative metallic finish: PVD via thermal evaporation is a common and effective solution for plastics and consumer goods.

Ultimately, vacuum coating is a powerful method for engineering surfaces with properties far beyond what the base material can offer alone.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Applying thin, durable layers to engineer surface properties |

| Core Methods | Physical Vapor Deposition (PVD) & Chemical Vapor Deposition (CVD) |

| Key Industries | Aerospace, Automotive, Medical, Electronics, Optics |

| Main Benefits | Enhanced Durability, Electrical Conductivity, Specific Optical Behaviors |

Ready to engineer superior surfaces for your products? KINTEK specializes in high-performance lab equipment and consumables for vacuum coating processes. Whether you need durable PVD coatings for tools or uniform CVD layers for electronics, our solutions are designed to meet the precise needs of your laboratory. Contact our experts today to discuss how we can enhance your coating capabilities and drive your innovation forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition