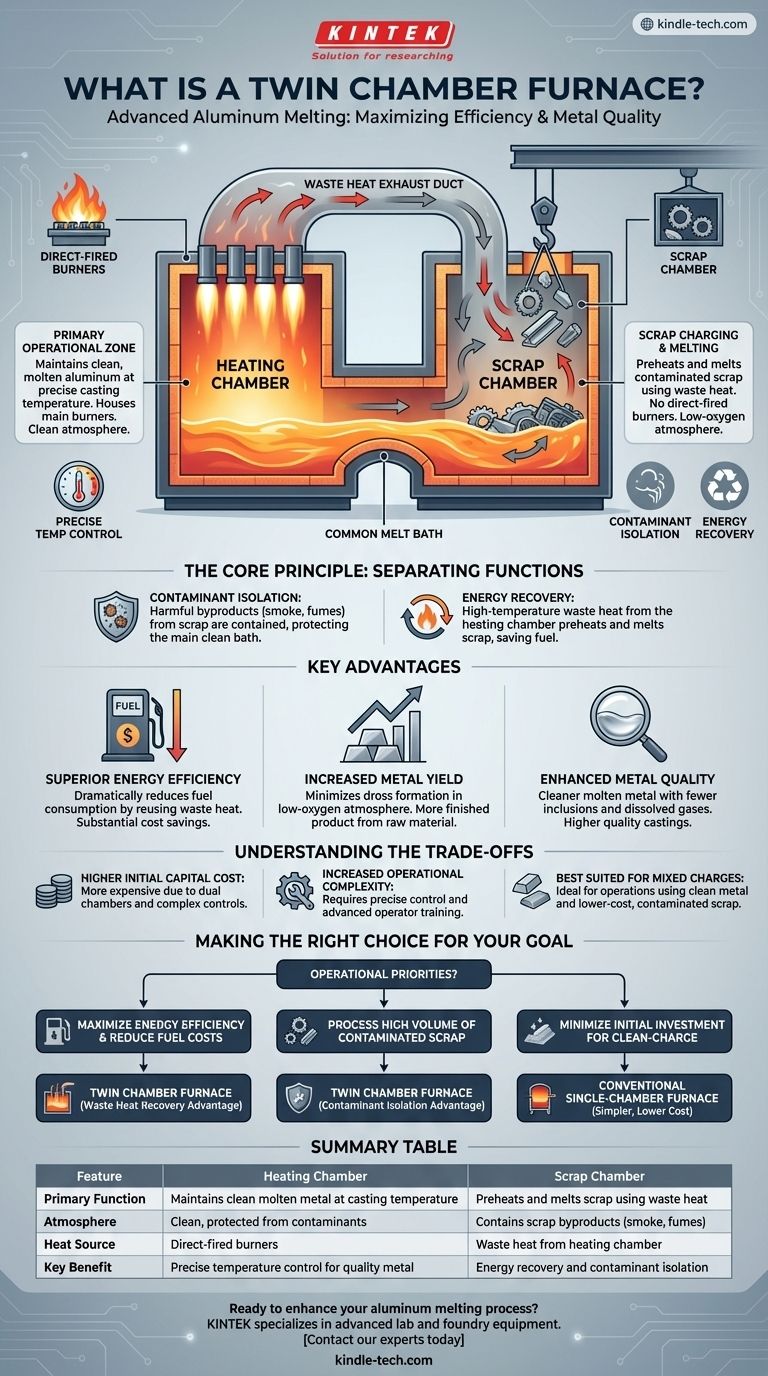

In essence, a twin chamber furnace is an advanced aluminum melting system that uses a clever dual-chamber design to maximize energy efficiency and metal quality. It integrates a primary heating chamber and a secondary scrap-melting chamber into a single unit. Although they share a common pool of molten metal, the key is that their atmospheres are kept separate.

The fundamental principle of a twin chamber furnace is to use the high-temperature waste heat from the primary heating chamber to preheat and melt scrap in the secondary chamber. This separation protects the main bath from contaminants while recovering energy that would otherwise be lost.

The Core Principle: Separating Functions for Efficiency

The effectiveness of a twin chamber furnace comes from its intelligent division of labor. Instead of performing all tasks in one space, it optimizes separate environments for distinct processes.

The Heating Chamber

This is the primary operational zone. It contains the main bath of clean, molten aluminum and houses the primary burners. Its sole focus is to efficiently maintain the liquid metal at the precise temperature required for casting.

The Scrap Chamber

This chamber is designed specifically for charging and melting scrap material, which may be contaminated with coatings, oils, or moisture. It operates without direct-fired burners.

The Common Melt Bath

A submerged opening, or "arch," connects the two chambers below the metal line. This allows the molten metal to flow freely between them, creating a single, unified bath while keeping the atmospheres above isolated.

The Divided Atmosphere

This separation is the most critical feature. The hot exhaust gases from the burners in the heating chamber are ducted directly into the scrap chamber. This allows the furnace to perform two key functions simultaneously:

- Energy Recovery: The waste heat, which would be vented in a standard furnace, is used to efficiently preheat and melt the scrap charge.

- Contaminant Isolation: Harmful byproducts from the scrap (like smoke from coatings) are contained within the scrap chamber and its exhaust system, never mixing with the clean atmosphere of the heating chamber. This prevents contamination of the main metal bath.

Key Advantages of the Twin Chamber Design

This separation of functions translates directly into significant operational benefits.

Superior Energy Efficiency

By recovering and reusing waste heat, these furnaces can dramatically reduce fuel consumption compared to conventional single-chamber designs. This results in substantial and continuous cost savings.

Increased Metal Yield

Melting scrap in a low-oxygen atmosphere created by the exhaust gases minimizes the formation of dross (aluminum oxide). Less metal is lost to oxidation, meaning more finished product is yielded from the same amount of raw material.

Enhanced Metal Quality

Because the main bath is shielded from the contaminants being burned off the scrap, the final molten metal is cleaner, with fewer inclusions and dissolved gases. This leads to higher-quality castings and reduced rejection rates.

Understanding the Trade-offs

While highly effective, this design is not a universal solution. It's important to recognize its specific context and limitations.

Higher Initial Capital Cost

The dual-chamber construction and the sophisticated control systems for managing airflow and pressure between the chambers make these furnaces more expensive to purchase and install than simpler designs.

Increased Operational Complexity

Operating a twin chamber furnace effectively requires more precise control over charging cycles, burner firing rates, and damper adjustments. This may necessitate more advanced operator training and a robust maintenance program.

Best Suited for Mixed Charges

The primary advantage is realized in operations that melt a combination of clean metal (ingots) and lower-cost, potentially contaminated scrap. The benefits are less pronounced for facilities that exclusively use one type of charge material.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your operational priorities.

- If your primary focus is maximizing energy efficiency and reducing long-term fuel costs: The twin chamber furnace's waste heat recovery offers a clear and significant advantage.

- If your primary focus is processing a high volume of coated or contaminated scrap: This furnace excels at isolating contaminants, leading to better metal yield and quality than single-chamber alternatives.

- If your primary focus is minimizing initial investment for a clean-charge operation: A simpler, conventional single-chamber furnace may be a more suitable, albeit less efficient, choice.

Ultimately, the twin chamber furnace represents a strategic investment in operational efficiency, superior metal quality, and environmental responsibility.

Summary Table:

| Feature | Heating Chamber | Scrap Chamber |

|---|---|---|

| Primary Function | Maintains clean molten metal at casting temperature | Preheats and melts scrap using waste heat |

| Atmosphere | Clean, protected from contaminants | Contains scrap byproducts (smoke, fumes) |

| Heat Source | Direct-fired burners | Waste heat from heating chamber |

| Key Benefit | Precise temperature control for quality metal | Energy recovery and contaminant isolation |

Ready to enhance your aluminum melting process with superior efficiency and metal quality? KINTEK specializes in advanced lab and foundry equipment, including twin chamber furnace solutions tailored to your operational needs. Our expertise helps you reduce fuel costs, increase metal yield, and achieve cleaner melts. Contact our experts today to explore how our solutions can optimize your production line!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan