In modern blacksmithing, the primary machine used for applying immense, controlled force is the hydraulic forging press. Unlike a traditional shop press used for bearings, a forging press is specifically designed to withstand the heat and repeated cycling required for shaping hot metal. It uses hydraulic fluid, a pump, and a cylinder to move a ram and apply tons of slow, steady pressure.

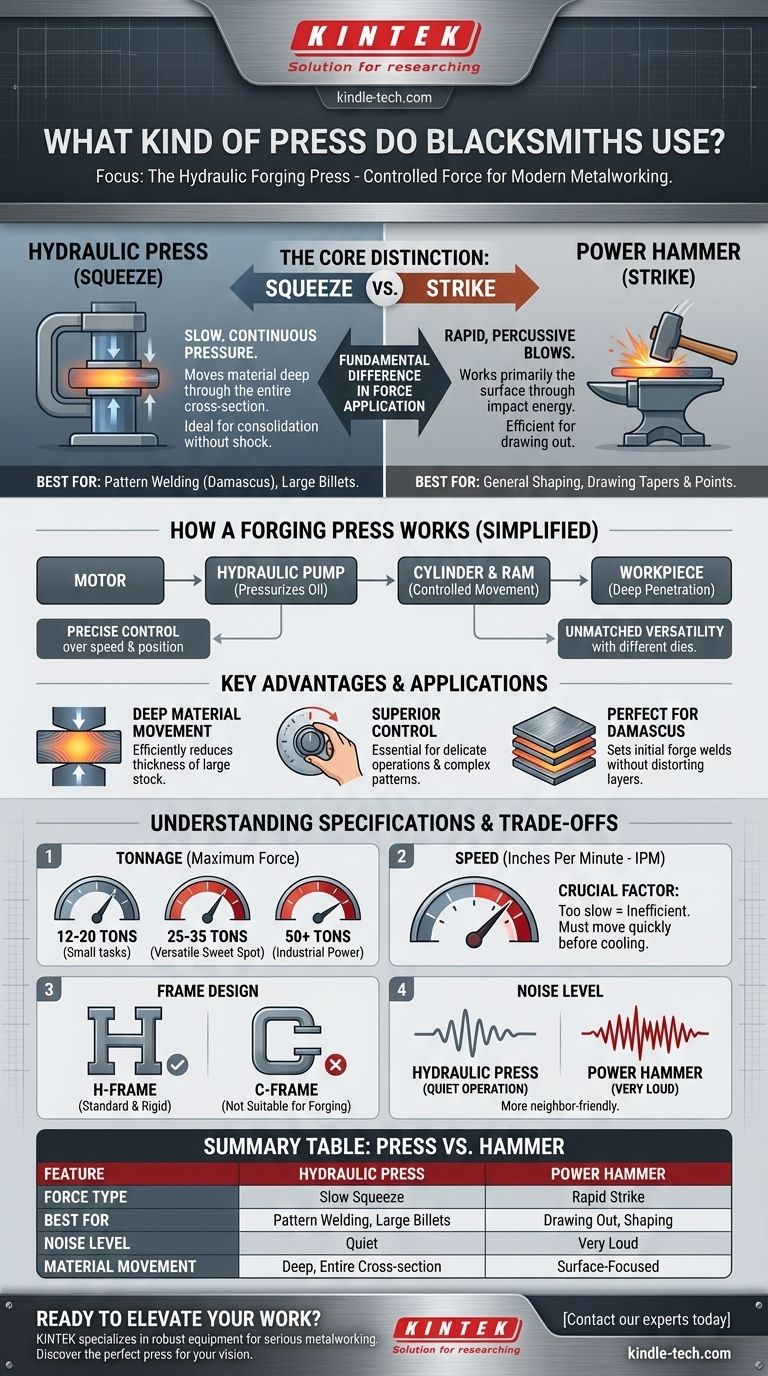

The core decision is not whether a press is "better" than a hammer, but understanding their fundamental difference. A hydraulic press delivers a slow, powerful squeeze that moves material through its entire thickness, while a power hammer delivers a rapid strike that primarily works the surface.

Why a Press? The Power of Squeezing

A hydraulic press has fundamentally changed how many smiths approach certain tasks, especially those involving large amounts of material or delicate patterns. Its operation is defined by controlled power.

How a Forging Press Works

A motor powers a hydraulic pump, which pressurizes oil and forces it into a large cylinder. This pressure acts on a piston connected to a ram, driving it down with tremendous force. Reversing a valve retracts the ram. This system allows for precise control over both the speed and position of the press tooling.

Deep Material Movement

The slow, continuous pressure from a press penetrates deep into the workpiece. This "squeezing" action moves the entire cross-section of the steel, making it incredibly efficient for reducing the thickness of large billets or consolidating a stack of layers for pattern-welded steel.

Unmatched Control and Versatility

The operator has complete control over the ram's movement. You can bring the dies together slowly, apply just enough pressure, and stop at a precise point. This control is essential for delicate operations and makes the press extremely versatile when paired with different types of dies.

Hydraulic Press vs. Power Hammer: The Real Difference

Choosing between a press and a power hammer is about choosing the right tool for a specific job. Their methods of applying force are opposites, giving them distinct advantages and disadvantages.

Force Application: Squeeze vs. Impact

A hydraulic press applies static, continuous force. Think of closing a vice very slowly. This force moves material evenly and is ideal for operations where you want to consolidate material without shock or vibration.

A power hammer applies dynamic, percussive force. Think of a rapid series of powerful hammer blows. The energy is transferred through impact, which is very effective for drawing material out (making it longer and thinner) but can cause layers in a billet to shift if not welded perfectly.

When to Choose a Press

A press excels at setting the initial forge weld on a pattern-welded (Damascus) billet. Its gentle squeeze sets the weld without the violent shock of a hammer, which can distort or shear the layers. It's also superior for working with very large stock or using tooling that requires a slow, controlled closure.

When to Choose a Power Hammer

A power hammer is often faster for drawing out material, like forging a long taper on a blade or tool. The rapid succession of blows and the natural rebound of the dies make it an aggressive and efficient shaping tool for general blacksmithing and sculptural work.

Understanding the Trade-offs and Key Specifications

Not all presses are created equal. The specifications directly impact what you can accomplish with the machine.

Tonnage: How Much Force?

Tonnage is the maximum force the press can exert.

- 12-20 Tons: Sufficient for many knifemaking tasks, including setting smaller Damascus billets and light drawing.

- 25-35 Tons: Considered a versatile sweet spot for most professional bladesmiths and blacksmiths, capable of handling larger billets and more aggressive forging.

- 50+ Tons: Industrial-level power for working with extremely large cross-sections of material.

Speed: The Overlooked Factor

Speed, measured in Inches Per Minute (IPM), is just as crucial as tonnage. A press that is too slow will allow the workpiece to cool before you can finish the operation, making it highly inefficient. A good forging press should move quickly enough to perform multiple squeezes in a single heat.

Frame Design: H-Frame is Standard

Forging presses almost exclusively use an H-frame design. This design, with two vertical supports, is extremely rigid and resists the twisting and flexing forces that occur when forging material that isn't perfectly centered. C-frame presses, which are open on three sides, are not suitable for the rigors of forging.

Noise and Safety

One of the most significant advantages of a press is its quiet operation compared to the deafening roar of a power hammer. This makes it a far better option for shops in residential areas. However, the immense force presents a serious safety hazard, and proper guards and careful operation are mandatory.

Making the Right Choice for Your Goal

The tool you choose should directly support the work you plan to do.

- If your primary focus is pattern-welded steel (Damascus): A hydraulic press is the superior tool for setting clean, reliable initial welds.

- If your primary focus is speed in general shaping and drawing out: A power hammer will often outperform a press for tasks like forging tapers and points.

- If your primary focus is working with very large billets or stock: A hydraulic press provides the deep-moving force necessary to work thick material efficiently.

- If your primary constraints are noise or a neighborhood setting: A hydraulic press is dramatically quieter and more neighbor-friendly than any power hammer.

Ultimately, understanding how each tool moves metal empowers you to build a workshop that truly serves your creative vision.

Summary Table:

| Feature | Hydraulic Press | Power Hammer |

|---|---|---|

| Force Type | Slow, continuous squeeze | Rapid, percussive strikes |

| Best For | Pattern welding, large billets | Drawing out, general shaping |

| Noise Level | Quiet | Very loud |

| Material Movement | Deep, entire cross-section | Surface-focused |

Ready to elevate your blacksmithing or bladesmithing work? A hydraulic forging press offers unmatched control for pattern welding, large billets, and quiet operation. KINTEK specializes in robust lab and workshop equipment, including presses designed for serious metalworking. Contact our experts today to find the perfect press for your creative vision!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport