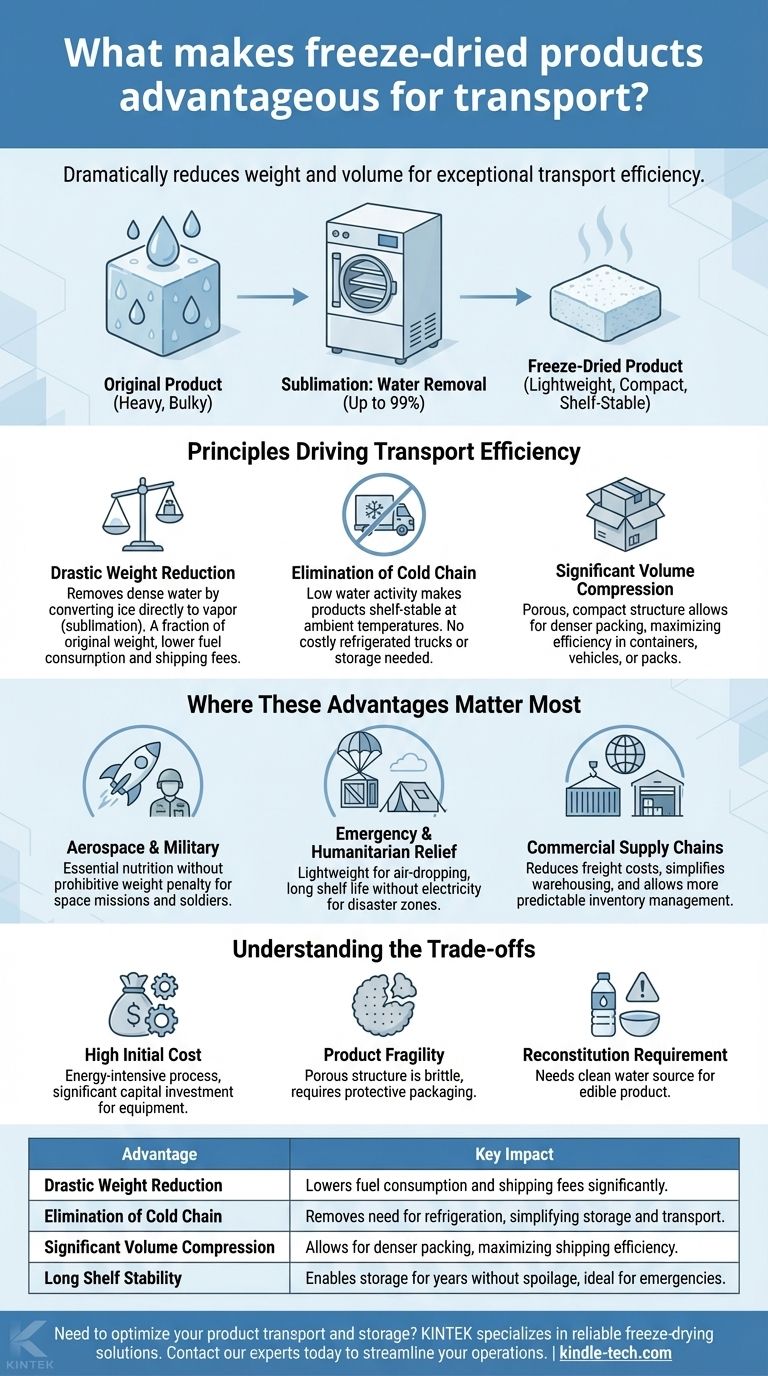

The primary transport advantage of freeze-dried products is their dramatic reduction in weight and volume. By removing nearly all water content through a process called sublimation, products become exceptionally lightweight and compact, which significantly lowers shipping costs and simplifies logistical challenges.

By removing up to 99% of a product's water, freeze-drying creates an unparalleled advantage in transport logistics. The core benefit extends beyond just weight reduction; it includes the elimination of the cold chain, fundamentally changing how and where these goods can be stored and deployed.

The Principles Driving Transport Efficiency

Freeze-drying, or lyophilization, isn't just about removing water. It's about how that water is removed, which directly creates its logistical benefits.

Drastic Weight Reduction

Water is dense and heavy. The freeze-drying process removes this weight by first freezing the product and then converting the ice directly into vapor, bypassing the liquid stage.

This results in a product that is a fraction of its original weight, directly translating to lower fuel consumption and shipping fees for any mode of transport.

Elimination of the Cold Chain

Because the water activity in freeze-dried products is so low, they are shelf-stable at ambient temperatures for extended periods.

This completely removes the need for a cold chain—the costly and energy-intensive network of refrigerated trucks, warehouses, and storage facilities required for fresh or frozen goods. This is a massive logistical simplification.

Significant Volume Compression

While preserving much of the original structure, the removal of water makes the product highly porous and often more compact.

This allows for denser packing, meaning more product can fit into a single shipping container, vehicle, or backpack, maximizing the efficiency of every shipment.

Where These Advantages Matter Most

The benefits of freeze-dried transport are most critical in environments where logistics are constrained by weight, space, or a lack of infrastructure.

Aerospace and Military Operations

For space missions, every kilogram sent into orbit costs thousands of dollars. For military personnel, every gram in their pack matters.

Freeze-drying provides essential nutrition without the prohibitive weight penalty, making it a standard for both astronauts and soldiers in the field.

Emergency and Humanitarian Relief

In disaster zones, infrastructure is often compromised or non-existent. There may be no electricity to power refrigeration units.

Freeze-dried meals and supplies are lightweight enough to be air-dropped and can be stored for years without spoiling, ensuring a reliable food source is available when needed most.

Commercial Supply Chains

Beyond extreme environments, these advantages apply to everyday commerce. Lightweight products reduce fuel costs for freight.

The long shelf life and lack of refrigeration needs simplify warehousing, reduce spoilage-related losses, and allow for more predictable inventory management.

Understanding the Trade-offs

While highly effective, the advantages of freeze-drying for transport are balanced by specific considerations.

High Initial Cost

Freeze-drying is an energy-intensive and slow process. The specialized equipment required represents a significant capital investment compared to simpler methods like air dehydration.

This cost must be justified by the logistical savings or the critical nature of the mission.

Product Fragility

The resulting porous structure that makes freeze-dried products easy to reconstitute also makes them brittle.

Proper, often bulky, packaging is required to protect the product from being crushed into powder during transit, which can slightly offset the space-saving benefits.

Reconstitution Requirement

The end product is not ready-to-eat. It requires a source of clean water for reconstitution.

In some contexts, like arid disaster zones, the logistical challenge may shift from transporting the food to transporting the clean water needed to make it edible.

Making the Right Choice for Your Goal

Selecting freeze-drying as a preservation method depends entirely on your operational priorities.

- If your primary focus is minimizing shipping cost and weight above all else: Freeze-drying is the superior choice, especially for high-value goods or long-distance transport where every gram counts.

- If your primary focus is long-term stability in unpredictable environments: The combination of a multi-year shelf life and no need for refrigeration makes freeze-drying ideal for emergency preparedness, military operations, and remote expeditions.

- If your primary focus is low-cost, high-volume production for local markets: The high capital and energy costs of freeze-drying may make traditional preservation or freezing methods more economically viable.

Ultimately, freeze-drying's transport advantages are unlocked when weight, space, and shelf stability are non-negotiable mission constraints.

Summary Table:

| Advantage | Key Impact |

|---|---|

| Drastic Weight Reduction | Lowers fuel consumption and shipping fees significantly. |

| Elimination of Cold Chain | Removes need for refrigeration, simplifying storage and transport. |

| Significant Volume Compression | Allows for denser packing, maximizing shipping efficiency. |

| Long Shelf Stability | Enables storage for years without spoilage, ideal for emergencies. |

Need to optimize your product transport and storage? KINTEK specializes in providing reliable laboratory equipment, including freeze-drying solutions, to help industries from pharmaceuticals to food science achieve superior product stability and logistical efficiency. Contact our experts today to discover how our lab equipment and consumables can streamline your operations and reduce costs.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- How are freeze dryers used in the pharmaceutical industry? Extend Drug Shelf Life & Stability

- What is the purpose of laboratory freeze drying? Preserve Sensitive Drugs & Biologics for Stability

- What types of liquid samples can be processed using a laboratory freeze dryer? Preserve Your Sensitive Materials

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What is the principle behind the process of extraction? Mastering Selective Solubility for Efficient Separation