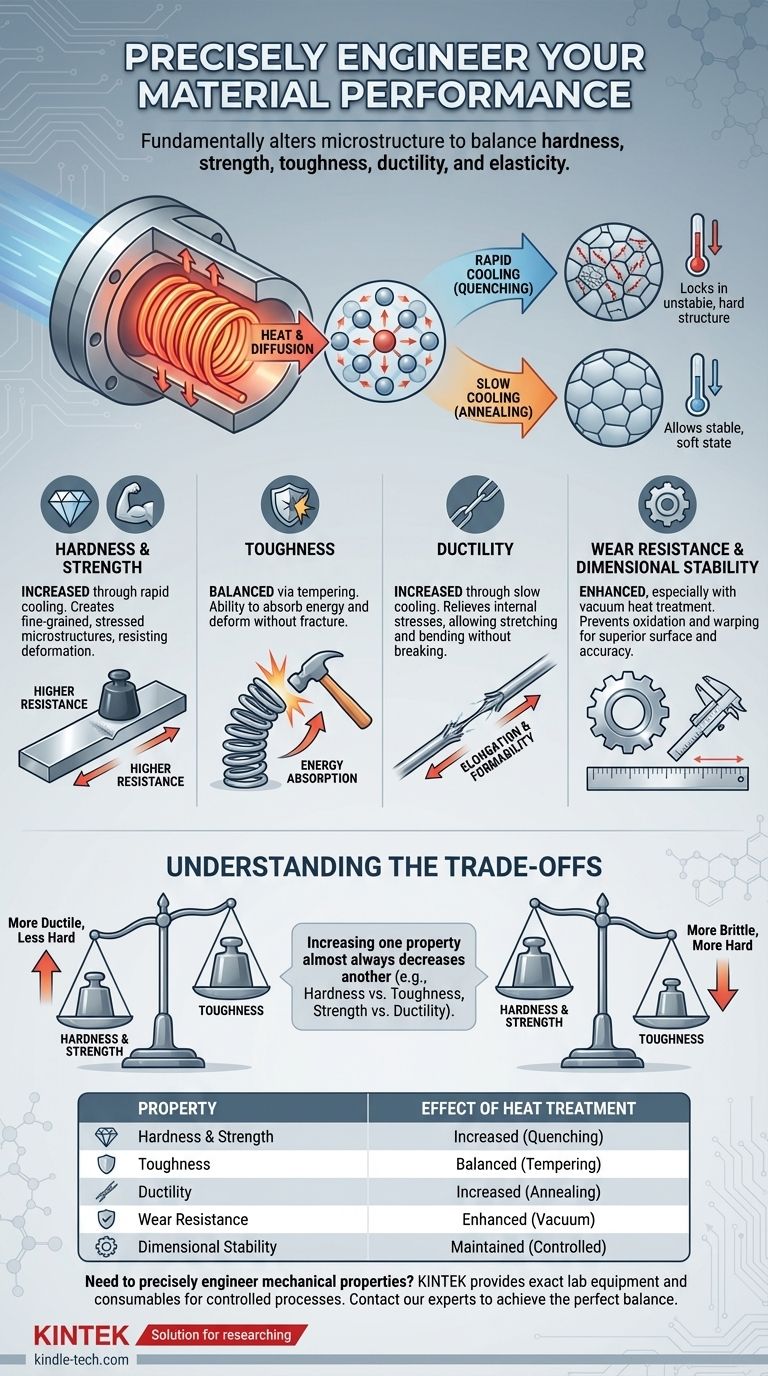

In short, heat treatment fundamentally alters nearly all of a metal's critical mechanical properties. By precisely controlling heating and cooling cycles, we can manipulate a material's internal microstructure, changing its hardness, strength, toughness, ductility, and elasticity to meet specific performance requirements. This process works by managing atomic diffusion and locking in desired crystalline structures.

The core purpose of heat treatment is not simply to make a metal harder or softer. It is a highly controlled engineering process used to achieve a deliberate balance of mechanical properties, often trading an increase in one attribute for a decrease in another.

The Foundation: How Heat Treatment Works

Heat treatment is a process of manipulating a metal's properties by modifying its internal atomic arrangement, known as its microstructure. This is not a chemical change but a physical restructuring.

Manipulating the Microstructure

Metals are composed of crystalline structures called grains. The size, shape, and arrangement of these grains dictate the material's mechanical behavior. Heat treatment provides the mechanism to change this arrangement.

The Role of Heating and Diffusion

Applying heat gives the metal's atoms the energy they need to move, or diffuse, from their fixed positions in the crystal lattice. As the temperature rises, atoms can rearrange themselves into different structural phases, some of which only exist at high temperatures.

The Critical Impact of Cooling

The rate of cooling is what "locks in" a specific microstructure at room temperature. A rapid cooling rate, known as quenching, traps unstable structures that are typically very hard and strong. A slow cooling rate, like annealing, allows the atoms to settle back into a more stable, stress-free state that is softer and more ductile.

Key Mechanical Properties and Their Transformations

Different heat treatment processes are designed to target specific properties. The most common changes involve a direct relationship or trade-off between the following attributes.

Hardness and Strength

Hardness (resistance to surface indentation) and strength (resistance to deformation) are often increased together. Treatments that create fine-grained or highly stressed microstructures make it more difficult for atomic planes to slip past one another, resulting in a harder, stronger material.

Toughness

Toughness is a material's ability to absorb energy and deform without fracturing. It is a combination of strength and ductility. A material can be strong but not tough if it is brittle.

Ductility

Ductility is the measure of a metal's ability to be stretched, bent, or drawn into a wire without breaking. Processes that relieve internal stresses and create uniform grain structures significantly increase ductility.

Wear Resistance and Dimensional Stability

Specialized methods like vacuum heat treatment enhance surface properties like wear resistance by preventing oxidation. These controlled environments also minimize the risk of warping, preserving the part's dimensional stability and ensuring superior performance.

Understanding the Trade-offs

Improving one mechanical property almost always comes at the expense of another. Understanding these compromises is critical for effective material selection and design.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off. As you increase a metal's hardness and strength, you almost invariably decrease its toughness. An extremely hard steel file, for example, is very brittle and will shatter if dropped, whereas a softer steel beam will bend.

The Strength vs. Ductility Conflict

Similarly, increasing a material's ultimate tensile strength often reduces its ductility. The strongest materials are frequently less capable of plastic deformation and will fracture with little warning.

The Risk of Distortion

The very act of heating and rapid cooling induces thermal stress. Without precise control, this can cause a component to warp, twist, or crack, compromising its dimensional accuracy and structural integrity.

Making the Right Choice for Your Application

The ideal heat treatment process is dictated entirely by the end goal for the component.

- If your primary focus is maximum hardness and wear resistance: A rapid quenching process followed by a low-temperature temper is the most effective approach.

- If your primary focus is maximum ductility and machinability: A full annealing cycle will soften the material, relieve internal stresses, and make it easier to form or machine.

- If your primary focus is a balanced profile of strength and toughness: Normalizing or a quench-and-temper process with a higher tempering temperature will provide a good compromise for structural applications.

Ultimately, heat treatment is the tool that transforms a generic alloy into a high-performance material precisely engineered for its task.

Summary Table:

| Property | Effect of Heat Treatment |

|---|---|

| Hardness & Strength | Increased through rapid cooling (quenching) |

| Toughness | Balanced via tempering; often trades off with hardness |

| Ductility | Increased through slow cooling (annealing) |

| Wear Resistance | Enhanced, especially with vacuum heat treatment |

| Dimensional Stability | Maintained through controlled heating/cooling cycles |

Need to precisely engineer the mechanical properties of your materials? KINTEK specializes in providing the exact lab equipment and consumables needed for controlled heat treatment processes. Whether you're developing new alloys or optimizing existing components, our solutions help you achieve the perfect balance of hardness, strength, and toughness. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- How does heat treatment process work? Tailor Material Properties for Your Application

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering