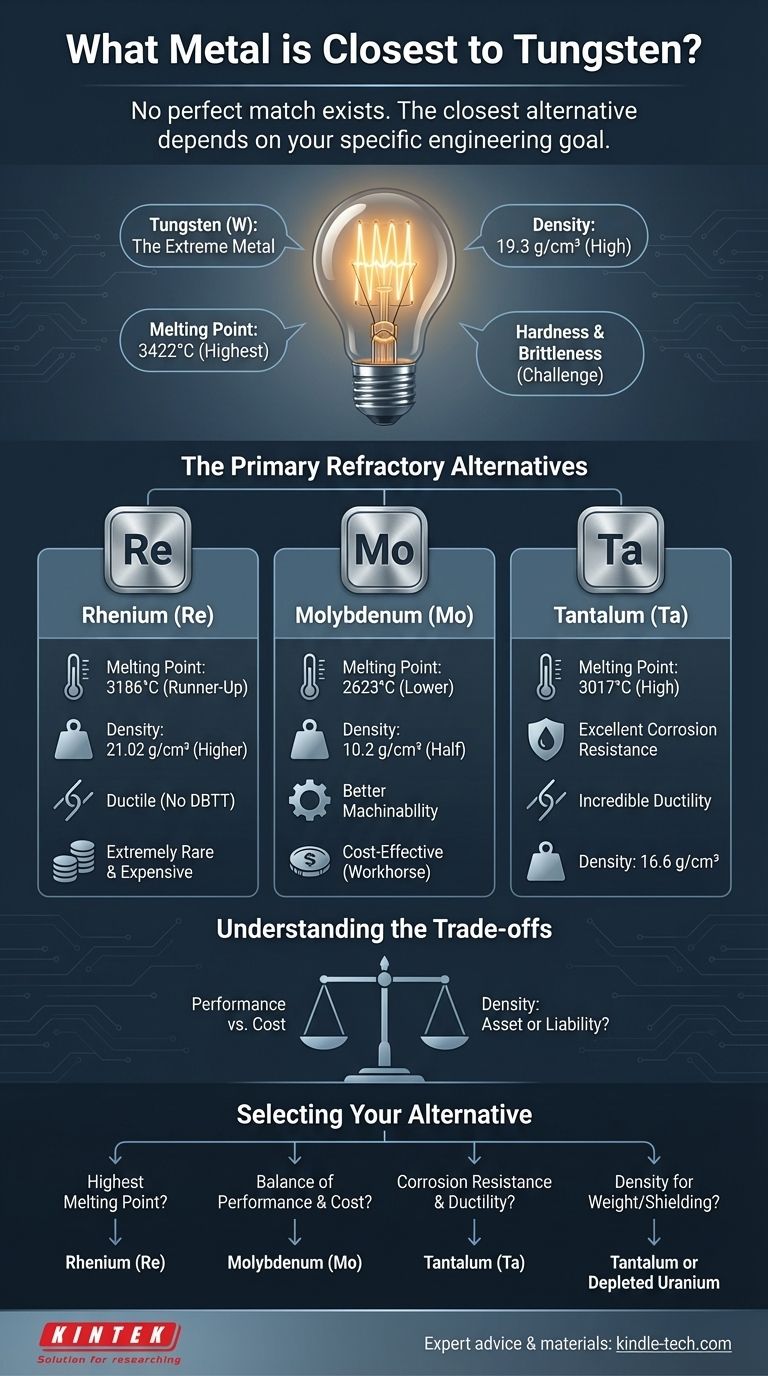

When searching for a direct alternative to tungsten, no single metal is a perfect match. The "closest" metal depends entirely on which of tungsten's extreme properties you need to replicate. For the highest melting point, Rhenium (Re) is the closest. For a more practical, high-temperature, and cost-effective substitute, Molybdenum (Mo) is the most common and logical choice.

The core issue is that tungsten's defining traits—its unmatched melting point, density, and hardness—come with significant trade-offs in cost and machinability. Finding an alternative is not about finding an identical replacement, but about making a strategic compromise based on your primary engineering goal.

Why Tungsten Is a Metal of Extremes

To find a suitable alternative, we must first understand what makes tungsten unique. It is not just one property but a combination of several that places it in a class of its own.

The Highest Melting Point

Tungsten's most famous characteristic is its melting point of 3422 °C (6192 °F), the highest of any metallic element. This makes it the default choice for applications like incandescent filament wires, plasma-facing components in fusion reactors, and high-temperature furnace elements.

Extreme Density and Hardness

With a density of 19.3 g/cm³, tungsten is one of the densest metals, nearly identical to gold. This density is crucial for applications requiring significant mass in a small volume, such as kinetic energy penetrators, counterweights, and radiation shielding.

When combined with carbon, it forms tungsten carbide, an exceptionally hard and wear-resistant ceramic used for cutting tools and abrasives.

The Challenge of Brittleness

Tungsten's primary drawback is its nature as a hard, brittle metal at room temperature. It has a high ductile-to-brittle transition temperature, meaning it must be heated to be worked effectively. Machining tungsten is exceptionally difficult, time-consuming, and costly.

The Primary Candidates: Refractory Metals

The most viable alternatives to tungsten come from the same family: the refractory metals. These are a class of metals defined by their extraordinary resistance to heat and wear.

Rhenium (Re): The Runner-Up in Melting Point

Rhenium has the second-highest melting point of any element at 3186 °C (5767 °F). It is also extremely dense (21.02 g/cm³), even denser than tungsten.

Crucially, rhenium does not have a ductile-to-brittle transition point, making it far more ductile and easier to form at low temperatures than tungsten. However, it is exceptionally rare and prohibitively expensive, limiting its use to highly specialized aerospace and thermocouple applications.

Molybdenum (Mo): The Practical Workhorse

Molybdenum is the most widely used substitute for pure tungsten. Its melting point of 2623 °C (4753 °F) is lower than tungsten's but still exceptionally high for most applications.

Its key advantage is a density that is about half of tungsten's (10.2 g/cm³) and significantly better machinability. It provides an excellent balance of high-temperature strength, stiffness, and thermal conductivity at a much lower cost.

Tantalum (Ta): The Ductility and Corrosion Champion

Tantalum is known for its incredible ductility and ease of fabrication, combined with outstanding corrosion resistance. Its melting point is high at 3017 °C (5463 °F), ranking just behind rhenium and tungsten.

While not as strong as tungsten at very high temperatures, tantalum's immunity to chemical attack makes it ideal for handling corrosive acids and for use in medical implants. Its density is high (16.6 g/cm³) but still lower than tungsten's.

Understanding the Trade-offs

Choosing a tungsten alternative is an exercise in balancing competing engineering requirements. There is no "better" metal, only one that is better suited for your specific task.

Performance vs. Cost

Cost is often the driving factor. Molybdenum is substantially cheaper than tungsten, which is itself far cheaper than tantalum. Rhenium is in another category entirely, often priced orders of magnitude higher than the others.

High-Temperature Strength vs. Machinability

This is the classic trade-off. Tungsten offers the ultimate high-temperature performance but is the most difficult to machine. Molybdenum offers a slight step down in temperature ceiling for a significant improvement in machinability. Tantalum is even more formable but cannot match the high-temperature strength of tungsten or molybdenum.

Density: An Advantage or a Burden?

Tungsten's high density is an asset for weighting and radiation shielding but a liability for aerospace or mobile applications. Molybdenum's lower density makes it a more attractive structural material where weight is a concern.

Selecting the Right Tungsten Alternative

Your decision must be guided by a clear understanding of your project's single most critical requirement.

- If your primary focus is the absolute highest melting point: Rhenium is the only metal that comes close, but be prepared for its extreme cost and limited availability.

- If your primary focus is a balance of high-temperature performance and cost-effectiveness: Molybdenum is the industry-standard substitute for tungsten in most furnace, heating, and structural applications.

- If your primary focus is corrosion resistance and ductility (formability): Tantalum is your best choice, provided you can accept a lower service temperature and strength compared to tungsten.

- If your primary focus is on density for weighting or shielding: Depleted uranium is a common, though highly regulated, alternative, while tantalum offers a non-toxic, high-density option.

By prioritizing your most critical property, you can confidently select an alternative that meets the engineering demands of your project.

Summary Table:

| Metal | Key Property | Best For | Key Limitation |

|---|---|---|---|

| Rhenium (Re) | Melting Point: 3186°C | Extreme heat applications (aerospace, thermocouples) | Extremely rare and expensive |

| Molybdenum (Mo) | Melting Point: 2623°C | Practical high-temp applications (furnace elements, structural) | Lower melting point than tungsten |

| Tantalum (Ta) | Excellent ductility & corrosion resistance | Chemical processing, medical implants | Lower high-temp strength |

Struggling to Choose the Right High-Temperature Metal?

At KINTEK, we specialize in providing expert solutions for your most demanding laboratory and industrial challenges. Whether you're working with tungsten, molybdenum, tantalum, or other refractory metals, our team can help you:

- Select the optimal material based on your specific requirements for temperature, strength, corrosion resistance, and budget

- Source high-quality lab equipment and consumables designed for extreme environments

- Optimize your processes with our technical expertise in high-temperature applications

Don't let material selection challenges slow down your innovation. Contact our experts today for personalized guidance on choosing and sourcing the right metals for your project.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance