When using a lyophilizer, the most critical problems to avoid are process failures that ruin the product or extend cycle times unnecessarily. These issues almost always stem from an imbalance between the rate of sublimation and the system's ability to remove the resulting water vapor, leading to product overheating, condenser overload, and vapor choking.

The core challenge in lyophilization is managing a delicate balance. You must apply enough energy to drive sublimation (ice turning to vapor) efficiently, but not so much that you overwhelm the system's capacity to trap that vapor, which can cause catastrophic product collapse.

The Central Conflict: Heat Input vs. Vapor Removal

Successful freeze-drying hinges on controlling the transition of ice directly into vapor, a process called sublimation. This requires carefully managing two opposing forces.

The Role of Heat and Vacuum

To drive sublimation, you apply heat to the product under a deep vacuum. The vacuum lowers the boiling point of water, allowing the ice to turn into vapor at very low temperatures.

The shelves in the lyophilizer provide the energy (heat) needed for the ice crystals in your product to sublimate. The goal is to do this as quickly as possible without damaging the product.

The Role of the Condenser

The condenser is the critical vapor trap. It is a refrigerated surface, significantly colder than the product, that captures the water vapor and turns it back into ice, preventing it from overwhelming the vacuum pump.

A lyophilizer's performance is ultimately limited by how quickly its condenser can trap this vapor.

Common Failure Points and Their Causes

Every major lyophilization problem can be traced back to losing the balance between sublimation rate and vapor removal capacity.

Product Collapse or Melt-back

This is the most common form of product failure. It occurs when the product's temperature rises above its critical collapse temperature during primary drying.

The product loses its solid structure, melts back, and can result in a shrunken, glassy, or sticky final cake with poor stability and long-term storage issues. This is a direct result of applying too much heat or insufficient vacuum.

Condenser Overload

Condenser overload happens when water vapor arrives at the condenser faster than it can be frozen onto the coils.

This causes the condenser temperature to rise, reducing its efficiency. As the condenser warms, its ability to trap vapor diminishes, leading to an increase in chamber pressure and risking product melt-back.

Vapor Choking

This is a physical bottleneck. Vapor choking occurs when you generate vapor so rapidly that it cannot physically pass through the port connecting the product chamber to the condenser.

Think of it as a traffic jam for water molecules. This restriction causes pressure in the product chamber to rise dramatically, even if the condenser is functioning perfectly. This pressure increase will quickly lead to product collapse.

Understanding the Trade-offs

Optimizing a lyophilization cycle requires balancing competing priorities. Understanding these trade-offs is key to avoiding the problems listed above.

Speed vs. Product Safety

The primary trade-off is between the speed of the drying cycle and the safety of the product. Applying more heat speeds up sublimation and shortens the cycle, but it significantly increases the risk of melt-back, condenser overload, and vapor choking.

A conservative, slower cycle is always safer for a valuable or unknown product. Aggressive, faster cycles are only possible when you have precisely characterized both your product's limits and your lyophilizer's capabilities.

Equipment Limitations

Every freeze-dryer has a maximum sublimation rate it can handle, defined by the refrigeration power of its condenser and the diameter of the vapor port. Pushing the process beyond this inherent physical limit will always result in failure.

Attempting a large batch of product with a high sublimation rate on a small laboratory unit is a common cause of vapor choking and condenser overload.

How to Ensure a Successful Lyophilization Cycle

Your approach should be dictated by your primary goal, whether it is guaranteeing product quality or maximizing throughput.

- If your primary focus is product quality and stability: Operate with a significant safety margin by keeping the product temperature several degrees below its known collapse temperature.

- If your primary focus is process efficiency: You must first determine your product's collapse temperature and your lyophilizer's maximum vapor flow rate to design the most aggressive (fastest) yet safe cycle possible.

- If you are troubleshooting a failed cycle: First, inspect the product for visual signs of collapse, then analyze process data for a sudden rise in chamber pressure, which indicates either vapor choking or condenser overload.

Ultimately, mastering lyophilization is about controlling the rate of sublimation to ensure your equipment can always keep up.

Summary Table:

| Common Problem | Primary Cause | Consequence |

|---|---|---|

| Product Collapse/Melt-back | Product temperature exceeds collapse temperature | Loss of structure, poor stability |

| Condenser Overload | Vapor generation exceeds condenser's freezing capacity | Rise in chamber pressure, risk of melt-back |

| Vapor Choking | Vapor generated too rapidly for vapor port | Pressure spike in chamber, product failure |

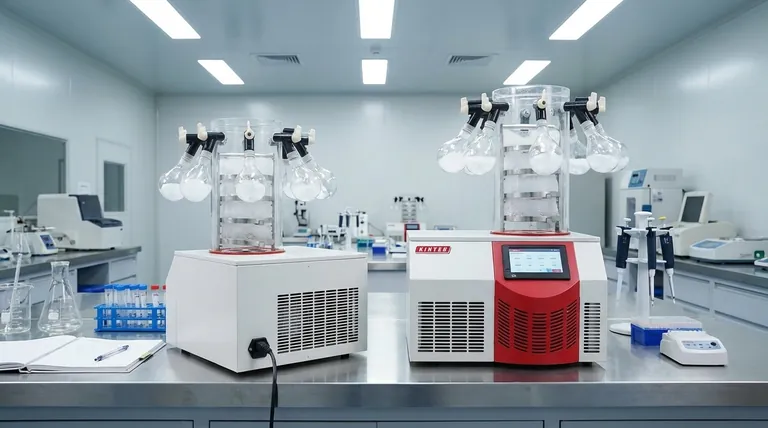

Optimize your freeze-drying process with KINTEK!

Are you struggling with lyophilizer failures, product collapse, or inefficient cycles? KINTEK specializes in high-performance lab equipment and consumables designed to meet the precise demands of laboratory freeze-drying. Our expertise ensures you achieve the perfect balance between heat input and vapor removal for reliable, high-quality results every time.

Let our experts help you select the right lyophilizer for your specific application and provide the support you need to avoid common pitfalls. Contact us today to discuss your laboratory needs and discover how KINTEK can enhance your lyophilization success.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Hybrid Tissue Grinding Mill

- Small Injection Molding Machine for Lab Use

People Also Ask

- What benefits do laboratory freeze dryers provide in chemical and biotechnological processes? Preserve Purity & Stability

- What are the key reasons to use a freeze dryer in laboratories? Preserve Sample Integrity for Reliable Research

- What are the key components of a Laboratory Freeze Dryer? Understand the 4 Core Systems for Successful Lyophilization

- What are the three primary stages of the freeze-drying process? Master Precise Lyophilization for Your Lab

- How does freeze drying compare to conventional freezing for biological material preservation? Achieve Long-Term, Shelf-Stable Preservation