In short, roll forming is used to create a vast array of metal products characterized by their long length and uniform cross-section. Key examples include structural shapes like C-channels and Z-purlins for construction, panels for metal roofing and siding, frames for solar panels and windows, and components for the automotive, appliance, and shelving industries.

The defining characteristic of a roll-formed product isn't its specific function, but its geometry. If you need to produce a long metal part with a consistent, complex profile in high volumes, roll forming is almost always the most efficient and cost-effective manufacturing process.

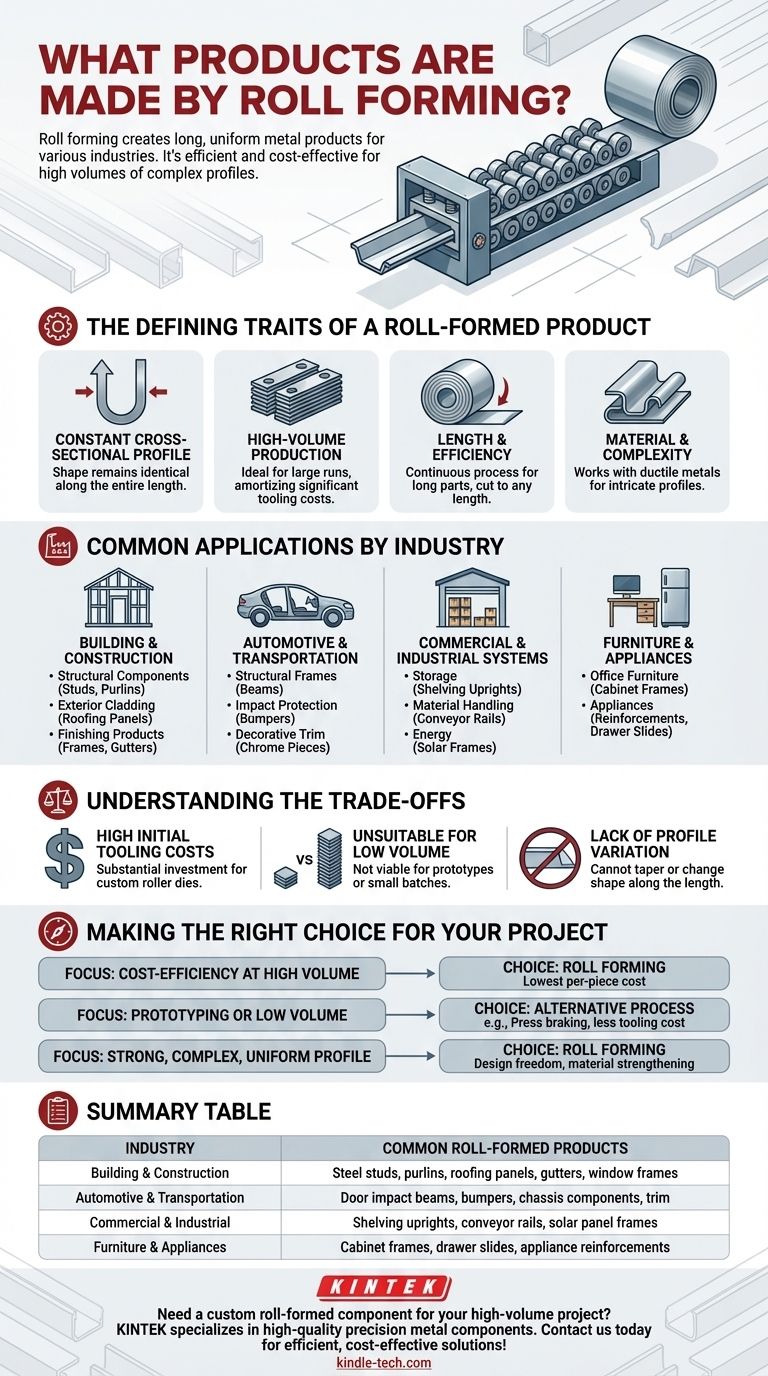

The Defining Traits of a Roll-Formed Product

To understand what is made with roll forming, you must first understand the process's core capabilities. A product is a good candidate for roll forming if it exhibits several key characteristics.

Constant Cross-Sectional Profile

This is the most fundamental requirement. The shape of the part must be the same along its entire length. A flat sheet of metal coil is progressively bent by a series of roller dies until it achieves its final, uniform profile.

High-Volume Production

The custom roller dies required for a specific profile represent a significant upfront investment in tooling. This cost is amortized over a large number of parts, making the process highly economical for high-volume runs but unsuitable for prototypes or small batches.

Length and Efficiency

Roll forming is a continuous process. Parts can be cut to virtually any length, limited only by shipping and handling logistics. This makes it ideal for producing long components like building studs, gutters, or conveyor rails with extreme efficiency and minimal waste.

Material and Complexity

The process works best with ductile metals like steel, aluminum, and stainless steel. It can create highly intricate and complex profiles with multiple bends, holes, and embossments—features that would be difficult or impossible to achieve with other methods like press braking or extrusion.

Common Applications by Industry

While the applications are nearly limitless, most roll-formed products fall into a few key sectors where efficiency, strength, and consistency are paramount.

Building & Construction

This is the largest market for roll-formed products. The process is responsible for the backbone of many modern metal buildings.

- Structural Components: Steel studs, tracks, purlins, and girts.

- Exterior Cladding: Corrugated roofing panels, siding, and soffits.

- Finishing Products: Door and window frames, gutters, and downspouts.

Automotive & Transportation

The automotive industry relies on roll forming for components that are both strong and lightweight. The process can work-harden the metal, increasing its yield strength.

- Structural Frames: Chassis components and reinforcement beams.

- Impact Protection: Bumpers and door impact beams.

- Decorative Trim: Chrome and stainless steel trim pieces.

Commercial & Industrial Systems

From warehouses to solar farms, roll forming creates the essential infrastructure for many commercial operations.

- Storage: Uprights and beams for industrial shelving and pallet racking.

- Material Handling: Rails for conveyor systems.

- Energy: Mounting frames and support structures for solar panels.

Furniture & Appliances

Even everyday items rely on the precision of roll-formed parts for their function and durability.

- Office Furniture: File cabinet frames and desk components.

- Appliances: Reinforcement frames for refrigerators and ovens, and high-precision drawer slides.

Understanding the Trade-offs

Despite its advantages, roll forming is not the solution for every manufacturing problem. Objectively understanding its limitations is critical for making an informed decision.

High Initial Tooling Costs

The primary barrier to entry is the cost of the custom roller die sets. For a new profile, this investment can be substantial, making the process economically unviable for small production runs.

Unsuitable for Low Volume

Due to the tooling costs and setup time, roll forming is a high-volume process. For prototypes, one-offs, or small batches, alternative methods like press braking or laser-cut-and-weld fabrication are far more practical.

Lack of Profile Variation

The cross-section must remain constant. You cannot use roll forming to create a part that tapers or changes shape along its length. Any such features must be added in a secondary, post-forming operation.

Making the Right Choice for Your Project

Your decision to use roll forming should be based on your project's specific priorities regarding volume, geometry, and cost.

- If your primary focus is cost-efficiency at high volume: Roll forming is the definitive choice for any part with a uniform profile, delivering the lowest per-piece cost.

- If your primary focus is prototyping or low-volume production: You must use an alternative process like press braking, which offers flexibility without the high upfront tooling investment.

- If your primary focus is creating a strong, complex, and uniform profile: Roll forming provides design freedom and material-strengthening benefits that are difficult to match.

Ultimately, roll forming is the definitive manufacturing process for creating consistent, complex metal profiles with unmatched efficiency at scale.

Summary Table:

| Industry | Common Roll-Formed Products |

|---|---|

| Building & Construction | Steel studs, purlins, roofing panels, gutters, window frames |

| Automotive & Transportation | Door impact beams, bumpers, chassis components, trim |

| Commercial & Industrial | Shelving uprights, conveyor rails, solar panel frames |

| Furniture & Appliances | Cabinet frames, drawer slides, appliance reinforcements |

Need a custom roll-formed component for your high-volume project? KINTEK specializes in providing high-quality lab equipment and consumables, including precision metal components for various industries. Our expertise ensures efficient, cost-effective solutions tailored to your needs. Contact us today to discuss how we can support your manufacturing requirements!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Small Injection Molding Machine for Lab Use

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- Why is a laboratory hydraulic press used for cold press molding? Achieve Superior Diamond-Aluminum Sintering Results

- How does a laboratory hydraulic press affect lithium-air battery cathodes? Precision Tuning for Peak Performance

- What is the maximum operating temperature of a water based hydraulic fluid? Ensure Fire Safety and System Reliability

- What makes a hydraulic press so strong? Harnessing Pascal's Law for Immense Force

- What are the steps involved in sample preparation? A Guide to Accurate and Reliable Analysis

- Does temperature affect hydraulic fluid? The Critical Role of Heat in System Performance

- What is the amount of sample required when making a KBr pellet? Achieve Perfect IR Spectra with the 100:1 Ratio

- What is the difference between hydro pneumatic press and hydraulic press? Choose the Right Press for Your Application