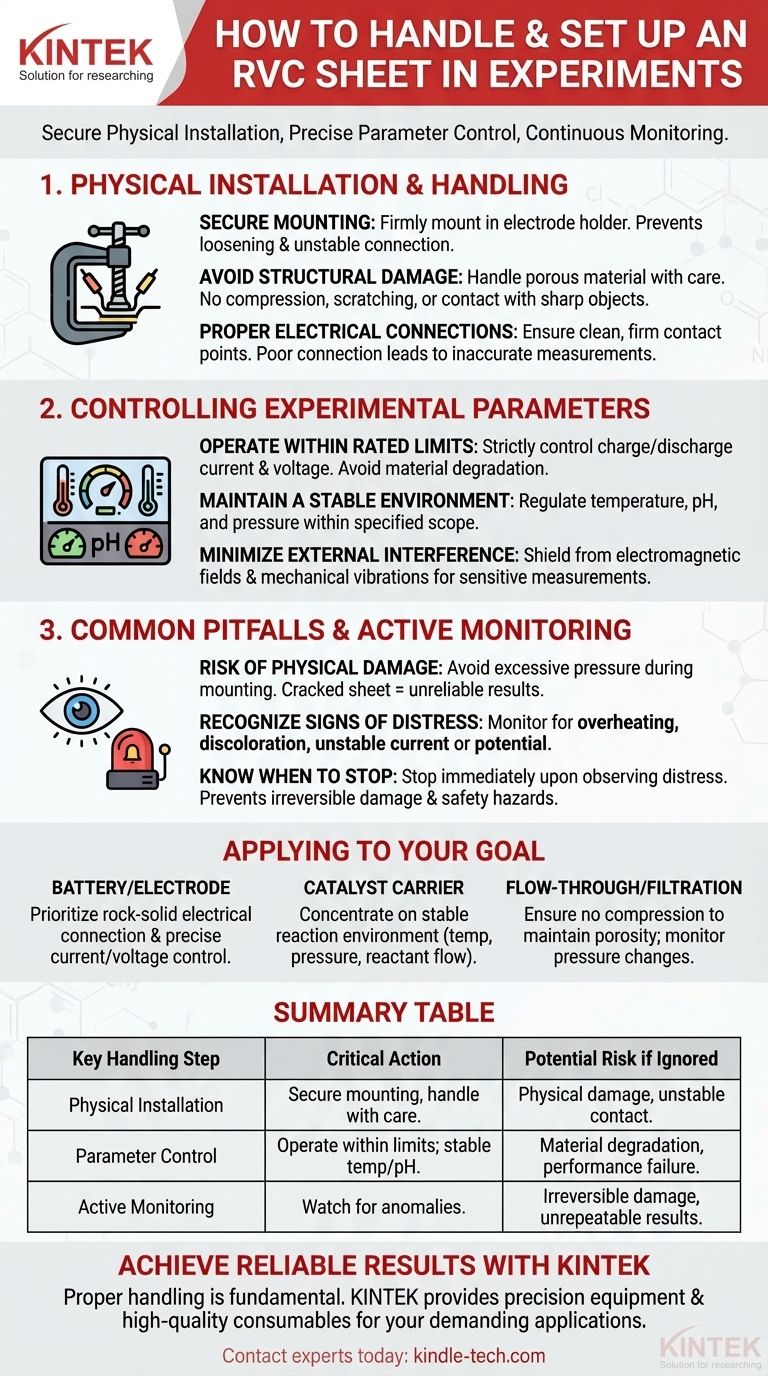

To properly handle an RVC sheet during an experiment, you must focus on three critical areas: secure physical installation, precise control of environmental conditions, and continuous monitoring. The sheet must be firmly mounted in an electrode holder to ensure stable electrical contact, while key parameters like temperature, pH, and current density are kept within specified limits to protect its delicate structure and ensure data integrity.

The core principle is maintaining stability at every level—mechanical, electrical, and environmental. The porous, fragile nature of Reticulated Vitreous Carbon (RVC) means that reliable experimental results depend entirely on preventing physical damage and operating within its intended chemical and electrical limits.

Physical Installation and Handling

Proper physical setup is the foundation of a successful experiment. Damage at this stage can compromise the entire process before it even begins.

Secure Mounting

The RVC sheet must be installed securely in an electrode holder or a comparable apparatus. This prevents any loosening or detachment during the experiment, which would disrupt the electrical connection and invalidate your results.

Avoiding Structural Damage

Handle the material with extreme care. Its porous, brittle structure is susceptible to damage from compression or contact with sharp objects. Any scratching or crushing can permanently alter its performance characteristics.

Ensuring Proper Electrical Connections

A stable and consistent electrical connection is paramount. Ensure the contact points are clean and firm, as a poor connection can lead to unstable current, inaccurate measurements, and potential damage to the material.

Controlling Experimental Parameters

RVC's performance is highly sensitive to its operating environment. Strict control over experimental conditions is not optional; it is essential for both safety and accuracy.

Operating Within Rated Limits

You must operate strictly within the material's specified performance parameters. When using RVC as an electrode, for example, control the charge/discharge current and voltage precisely to avoid degradation.

Maintaining a Stable Environment

Control factors such as temperature, pH, and pressure according to your experimental design. Avoid exposing the RVC sheet to extreme conditions that fall outside its operational scope, as this can lead to performance failure.

Minimizing External Interference

For sensitive electrochemical measurements, protect the setup from external interference. Electromagnetic fields and even mechanical vibrations can introduce noise and affect the accuracy of your potential and current readings. Shielding or grounding may be necessary.

Common Pitfalls and Active Monitoring

Constant vigilance during the experiment allows you to identify issues before they compromise your data or damage the equipment.

The Risk of Physical Damage

The most common failure point is physical mishandling. Never apply excessive pressure when mounting the sheet. A cracked or compressed RVC sheet has an altered surface area and flow dynamic, making results unreliable and unrepeatable.

Recognizing Signs of Distress

Closely monitor the working state of the RVC sheet throughout the experiment. Be alert for any abnormalities such as overheating, discoloration, or an unstable current or potential.

Knowing When to Stop

If you observe any signs of distress, stop the experiment immediately. Continuing to operate under abnormal conditions risks irreversible damage to the RVC sheet and can create a potential safety hazard.

How to Apply This to Your Goal

Your specific application dictates which parameters require the most attention.

- If your primary focus is battery or electrode performance: Prioritize a rock-solid electrical connection and meticulous control over the charge/discharge current and voltage.

- If your primary focus is using it as a catalyst carrier: Concentrate on maintaining a stable reaction environment, with precise control over temperature, pressure, and reactant flow.

- If your primary focus is flow-through analysis or filtration: Ensure the mounting does not compress the sheet, which would alter its porosity and flow characteristics, and monitor for pressure changes.

Ultimately, treating the RVC sheet as a precision instrument is the key to achieving valid and repeatable results.

Summary Table:

| Key Handling Step | Critical Action | Potential Risk if Ignored |

|---|---|---|

| Physical Installation | Secure mounting in electrode holder; handle with care to avoid compression. | Physical damage, unstable electrical contact, invalid data. |

| Parameter Control | Operate within rated current/voltage limits; maintain stable temperature & pH. | Material degradation, performance failure, safety hazards. |

| Active Monitoring | Watch for overheating, discoloration, or unstable readings. | Irreversible damage to the RVC sheet, unrepeatable results. |

Achieve Reliable and Repeatable Results with KINTEK

Proper handling of sensitive materials like Reticulated Vitreous Carbon (RVC) is fundamental to your lab's success. Whether your application is in electrochemistry, catalysis, or filtration, the precision of your equipment and consumables directly impacts your data's integrity.

KINTEK specializes in providing high-quality lab equipment and consumables designed for demanding applications. We understand the critical need for stability and precision in your experiments.

Let us help you enhance your lab's capabilities:

- Precision Equipment: Ensure stable electrical connections and accurate parameter control.

- High-Quality Consumables: Source reliable materials that perform to specification.

- Expert Support: Get guidance on best practices for setup and operation.

Don't let improper handling compromise your research. Contact our experts today to discuss how KINTEK can support your specific laboratory needs and help you achieve superior results.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Automatic Laboratory Heat Press Machine

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the difference between hot mounting and cold mounting? Choose the Right Method for Your Sample

- What is the process of mounting in metallurgy? A Guide to Perfect Specimen Preparation

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity