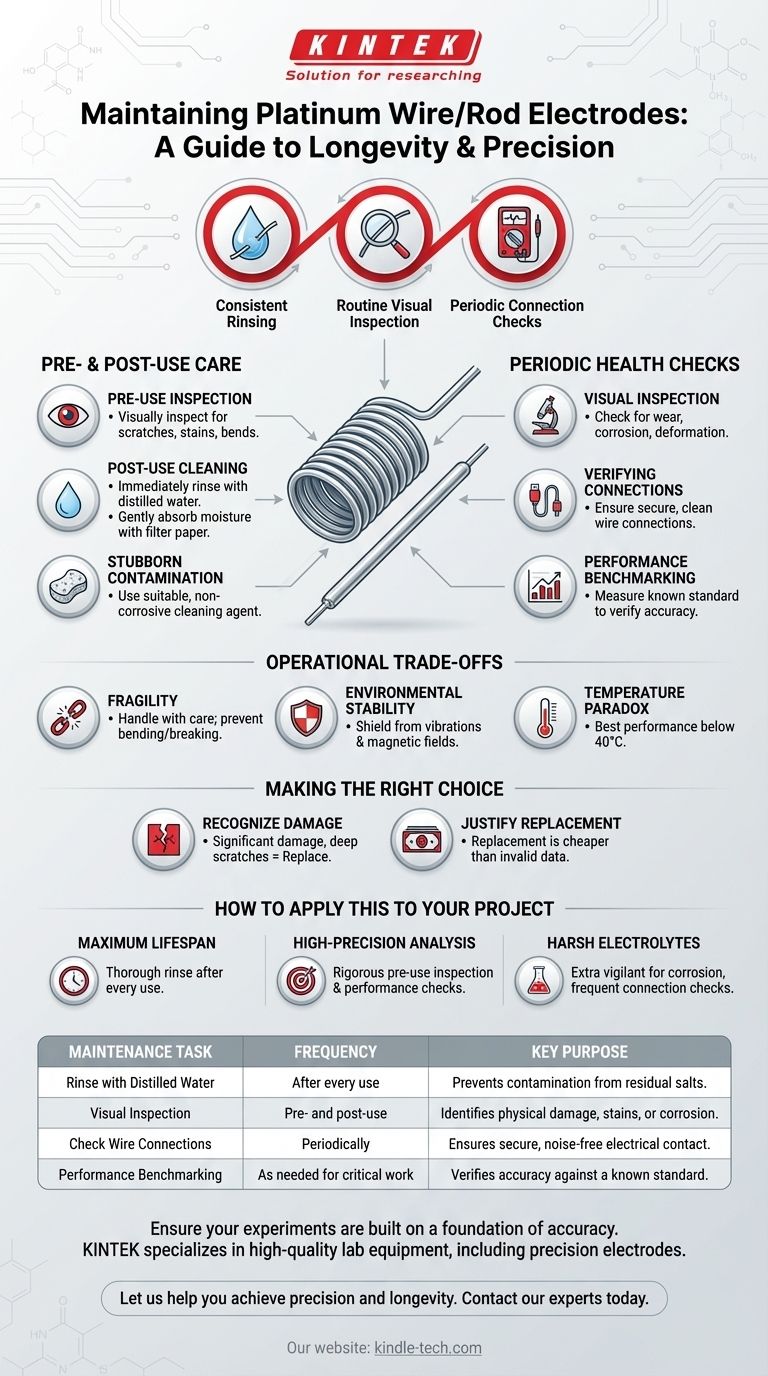

The regular maintenance of a platinum wire or rod electrode centers on three core practices. These are consistent rinsing with distilled water after every use, routine visual inspection for any physical damage or contamination, and periodic checks of the wire connections to ensure secure, reliable conductivity.

The goal of platinum electrode maintenance is not merely cleanliness, but the preservation of its uniquely stable and conductive surface. Neglecting these simple procedures can compromise the very properties—inertness and high conductivity—that make platinum essential for accurate electrochemical measurements.

A Routine for Longevity: Pre- and Post-Use Care

Proper care before and after each experiment is the foundation of electrode health. This routine prevents cross-contamination and cumulative damage.

The Pre-Use Inspection

Before any measurement, visually inspect the electrode's surface. Look for obvious scratches, stains, physical bends, or any other form of damage.

Contaminants or deformations on the platinum surface can directly interfere with electrochemical reactions, leading to inaccurate results.

The Post-Use Cleaning Protocol

Immediately after use, remove the electrode from the electrolyte. Rinse it thoroughly with distilled water to wash away residual salts and impurities.

After rinsing, gently absorb the remaining moisture with a clean filter paper. Avoid rubbing the delicate wire. This prevents contaminants from drying and crystallizing on the active surface.

Handling Stubborn Contamination

If stubborn stains persist after rinsing, a suitable cleaning agent may be used. It is critical to select a cleaner that is not corrosive to platinum to avoid damaging the electrode.

Periodic Health Checks for Peak Performance

Beyond daily care, periodic checks ensure the electrode remains a reliable instrument over its entire lifespan.

Visual Inspection for Degradation

On a regular basis, examine the electrode for subtle signs of wear, corrosion, or deformation that might develop over time. Catching these issues early can prevent failed experiments.

Verifying Electrical Connections

Periodically check the wire connections leading to your instrument. A loose or corroded connection can introduce significant noise and error into your measurements. Ensure the contact is clean and secure.

Performance Benchmarking

For critical applications, check that the electrode's performance is normal by measuring a known standard. A deviation in the expected potential or current is a clear sign that the electrode requires attention or replacement.

Understanding the Operational Trade-offs

While robust, platinum electrodes are not indestructible. Understanding their limitations is key to preserving their function.

The Fragility of the Wire

A platinum wire electrode is physically delicate and fragile. Always handle it with care to prevent bending or breaking, which would permanently alter its electrochemical properties.

Environmental Stability

For the most stable and repeatable measurements, the electrode should be shielded from external disturbances. This includes mechanical vibrations and strong magnetic fields that can interfere with the results.

The Temperature Paradox

Although platinum has excellent resistance to high temperatures, its performance and lifespan are best preserved when used at lower temperatures, typically below 40°C. Consistently high temperatures can accelerate degradation.

Making the Right Choice: Treat or Replace

When an issue is found, you must decide whether to attempt treatment or replace the unit entirely.

Recognizing Irreversible Damage

Significant physical damage, deep scratches, or a persistent, uncorrectable decline in performance are clear indicators that the electrode has reached the end of its useful life and should be replaced.

The Justification for Replacement

If performance becomes questionable, replacement is the safest course of action. The cost of a new electrode is often minor compared to the cost of invalid data or repeating entire experiments.

How to Apply This to Your Project

Your maintenance focus may shift slightly depending on your primary objective.

- If your primary focus is maximum lifespan and routine use: The non-negotiable habit is a thorough rinse with distilled water after every single use.

- If your primary focus is high-precision quantitative analysis: Rigorous pre-use visual inspection and periodic performance checks with a standard are absolutely critical.

- If your primary focus is working in harsh electrolytes: Be extra vigilant in your inspections for any signs of corrosion and check your electrical connections more frequently.

Ultimately, consistent and mindful care is the key to ensuring your platinum electrode provides accurate and repeatable results for its entire lifespan.

Summary Table:

| Maintenance Task | Frequency | Key Purpose |

|---|---|---|

| Rinse with Distilled Water | After every use | Prevents contamination from residual salts. |

| Visual Inspection | Pre- and post-use | Identifies physical damage, stains, or corrosion. |

| Check Wire Connections | Periodically | Ensures secure, noise-free electrical contact. |

| Performance Benchmarking | As needed for critical work | Verifies accuracy against a known standard. |

Ensure your experiments are built on a foundation of accuracy. Properly maintained lab equipment is non-negotiable for reliable results. KINTEK specializes in high-quality lab equipment and consumables, including precision electrodes, to serve your laboratory's exact needs.

Let us help you achieve precision and longevity in your work. Contact our experts today to discuss your specific requirements and find the perfect solutions for your lab.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Gold Disc Electrode

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is the rotating ring disk electrode method? Unlock Real-Time Reaction Analysis

- What is the common role of a platinum disk electrode? A Guide to Its Primary Use as a Working Electrode

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights