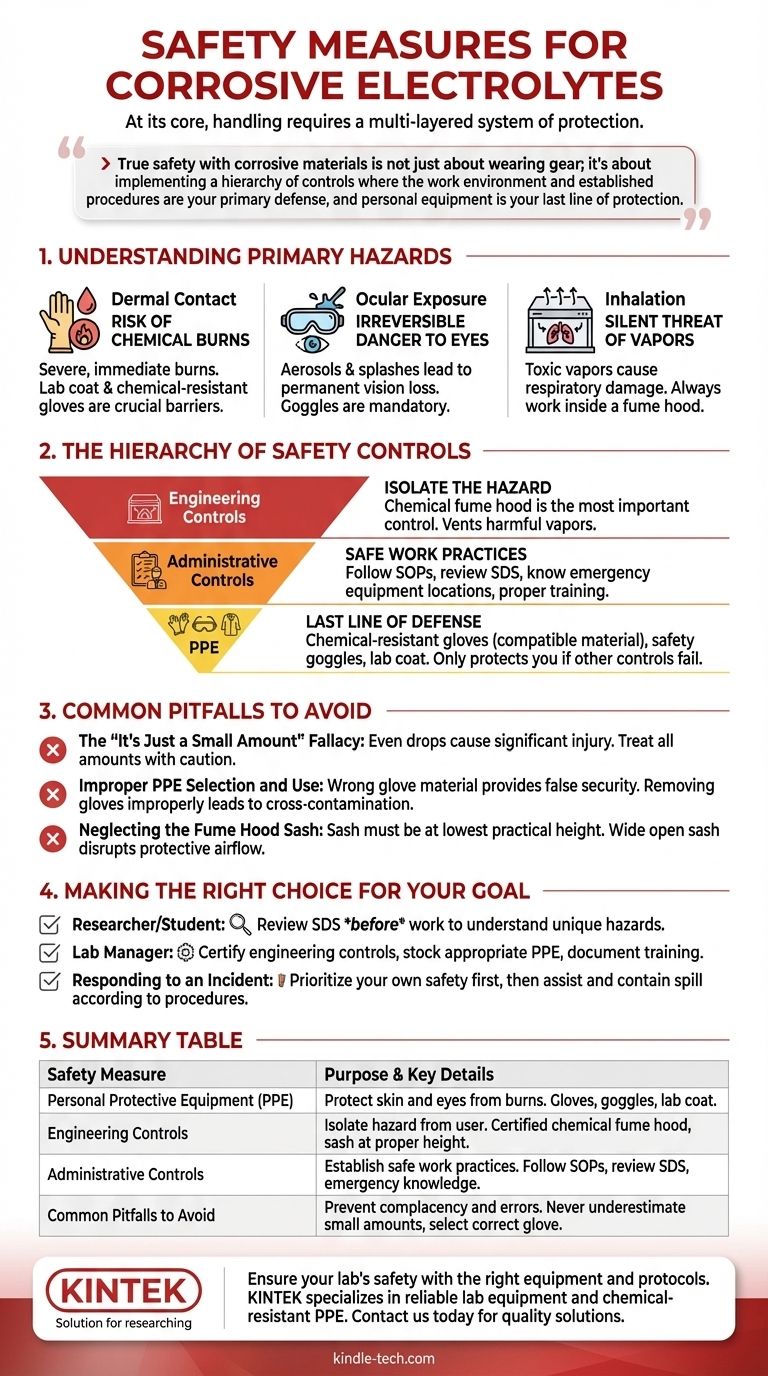

At its core, handling corrosive electrolytes safely requires a multi-layered system of protection. The absolute minimum safety measures include wearing appropriate Personal Protective Equipment (PPE) such as chemical-resistant gloves and safety glasses or goggles. All work must be conducted within a properly functioning chemical fume hood to prevent the inhalation of hazardous vapors or fumes.

True safety with corrosive materials is not just about wearing gear; it's about implementing a hierarchy of controls where the work environment and established procedures are your primary defense, and personal equipment is your last line of protection.

Understanding the Primary Hazards

Before using any safety equipment, it is critical to understand the specific dangers that corrosive electrolytes present. These materials can cause severe, often irreversible, damage through multiple exposure routes.

Dermal Contact: The Risk of Chemical Burns

Corrosive electrolytes can cause immediate and severe chemical burns upon contact with the skin. The severity depends on the chemical's concentration and the duration of the exposure.

A lab coat, in addition to gloves, provides a crucial barrier to protect your skin and clothing from accidental splashes.

Ocular Exposure: The Irreversible Danger to Your Eyes

Your eyes are exceptionally vulnerable to the aerosols and splashes from corrosive materials. Even a minor incident can lead to permanent vision loss.

For this reason, safety glasses are a minimum requirement, and chemical splash goggles offer superior protection against unexpected events.

Inhalation: The Silent Threat of Vapors

Many electrolytes release toxic or corrosive vapors. Inhaling these can cause severe damage to your respiratory tract, leading to acute injury or long-term health complications.

This is the primary reason why work must be performed inside a fume hood, which actively pulls harmful air away from you.

The Hierarchy of Safety Controls

Professional safety practice prioritizes controls that remove the hazard over those that just protect the individual. This is known as the hierarchy of controls.

Engineering Controls: Your First Line of Defense

These are changes to the work environment designed to isolate you from the hazard.

The chemical fume hood is the most important engineering control for this task. It contains the corrosive material and its vapors, venting them safely out of your workspace.

Administrative Controls: Safe Work Practices

These are the procedures and protocols you follow to work safely.

This includes having a Standard Operating Procedure (SOP) for the task, receiving proper training, and always knowing the location of emergency equipment like eyewash stations and safety showers. Reviewing the Safety Data Sheet (SDS) for the specific chemical is a critical part of this.

Personal Protective Equipment (PPE): Your Last Line of Defense

PPE is essential, but it is designed to protect you if engineering and administrative controls fail.

Chemical-resistant gloves are mandatory. It is vital to select a glove material (e.g., nitrile, neoprene) that is compatible with the specific electrolyte you are using.

Common Pitfalls to Avoid

Complacency is the greatest risk in any lab environment. Avoiding common mistakes is just as important as following the correct procedures.

The "It's Just a Small Amount" Fallacy

Even a few drops of a highly corrosive material can cause a significant injury, especially to the eyes. Treat every amount with the same high level of respect and caution.

Improper PPE Selection and Use

Wearing the wrong type of glove can provide a false sense of security, as the chemical may permeate it quickly. Likewise, taking gloves off improperly can lead to cross-contamination.

Neglecting the Fume Hood Sash

A fume hood is only effective when the sash (the sliding glass window) is kept at the lowest practical height. Working with the sash wide open negates its protective function by disrupting the airflow.

Making the Right Choice for Your Goal

Your approach to safety should be proactive, not reactive. Use this checklist to ensure you are prepared for your specific role.

- If you are a researcher or student: Always review the Safety Data Sheet (SDS) for the specific electrolyte before starting any work to understand its unique hazards.

- If you are a lab manager: Ensure all engineering controls are certified annually, appropriate PPE is fully stocked, and all personnel training is documented and up-to-date.

- If you are responding to an incident: Prioritize your own safety first, then assist others and contain the spill according to your lab's established emergency procedures.

A disciplined and informed approach transforms potential hazards into manageable risks, ensuring both your safety and the integrity of your work.

Summary Table:

| Safety Measure | Purpose | Key Details |

|---|---|---|

| Personal Protective Equipment (PPE) | Protect skin and eyes from chemical burns | Chemical-resistant gloves, safety goggles, lab coat |

| Engineering Controls | Isolate hazard from the user | Use a certified chemical fume hood with sash at proper height |

| Administrative Controls | Establish safe work practices | Follow SOPs, review SDS, know emergency equipment locations |

| Common Pitfalls to Avoid | Prevent complacency and errors | Never underestimate small amounts; select correct glove material |

Ensure your lab's safety with the right equipment and protocols. KINTEK specializes in providing reliable lab equipment and consumables, including fume hoods and chemical-resistant PPE, to help you manage corrosive materials safely. Contact us today to discuss your laboratory safety needs and let our experts support your research with quality solutions.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Gold Disc Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Copper Sulfate Reference Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis

- What role does a water-jacketed electrolytic cell play in variable-temperature electrochemical corrosion measurements?

- What is the difference between electrolytic corrosion cell and electrochemical corrosion cell? Understand the Driving Force Behind Corrosion

- What type of electrode system is the coating evaluation electrolytic cell designed for? Unlock Precise Coating Analysis

- How does a three-electrode electrolytic cell function? Precision Testing for 8620 Steel in Corrosive Environments