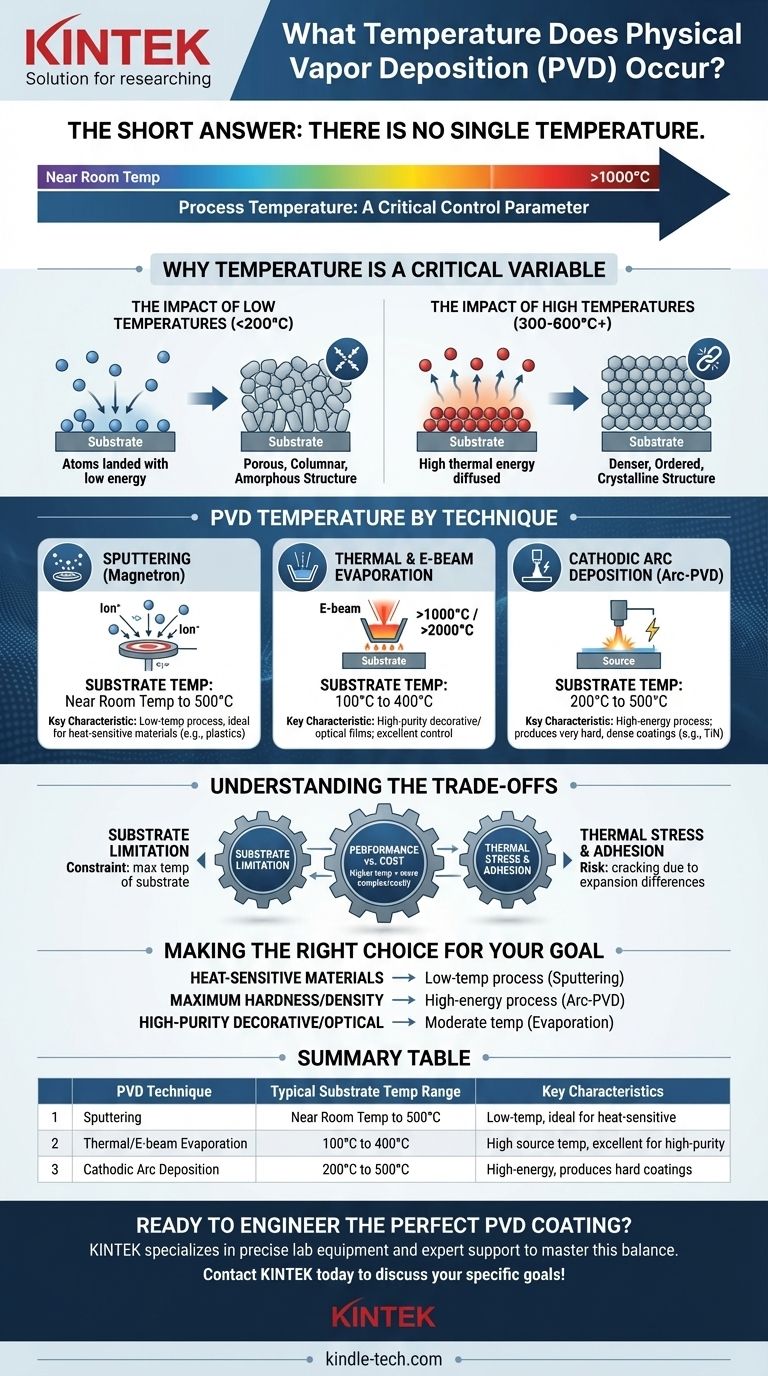

The short answer is there is no single temperature for Physical Vapor Deposition (PVD). The process temperature is not a fixed value but a critical control parameter that varies dramatically, ranging from near room temperature to over 1000°C. It is deliberately chosen based on the specific PVD technique, the material being deposited, the substrate being coated, and the desired properties of the final film.

The core principle to understand is that temperature is a tool used to control the final coating's quality. Higher temperatures generally give atoms more energy to arrange themselves into a denser, more adherent film, but the right temperature is always a trade-off between the desired outcome and the physical limitations of the material you are coating.

Why Temperature is a Critical Variable in PVD

In any PVD process, atoms from a solid source are vaporized, travel through a vacuum, and condense onto a substrate. The substrate's temperature directly dictates what happens when those atoms land.

The Impact of Low Temperatures

At lower substrate temperatures (e.g., below 200°C), arriving atoms have very little thermal energy. They essentially "stick where they land" with limited ability to move across the surface.

This results in a film structure that is often amorphous or has fine grains, with a porous, columnar growth pattern. While suitable for some applications, these films may have lower density and adhesion.

The Impact of High Temperatures

At higher substrate temperatures (e.g., 300-600°C or more), arriving atoms have significant thermal energy. They can diffuse and migrate across the surface before settling into a low-energy position.

This mobility allows atoms to form a denser, more ordered, and often crystalline film structure. The result is typically superior adhesion, higher hardness, and lower internal stress.

PVD Temperature by Technique

The term "PVD" covers several distinct methods, each with its own characteristic temperature profile. It's crucial to distinguish between the source temperature (used to create the vapor) and the substrate temperature (where the film grows).

Sputtering (Magnetron Sputtering)

Sputtering is fundamentally a momentum-transfer process, not a thermal one. High-energy ions bombard a source (the "target"), knocking atoms loose.

Because the source isn't melted, sputtering can be a low-temperature process. Substrates can be kept near room temperature, making it ideal for coating heat-sensitive materials like plastics and polymers. However, substrates are often intentionally heated to 100-500°C to improve film density and adhesion.

Thermal & E-beam Evaporation

Evaporation relies on heat to turn the source material into a vapor.

- Thermal Evaporation: A resistive boat or coil is heated to extreme temperatures (often >1000°C) to melt and then evaporate the source material.

- E-beam Evaporation: A high-energy electron beam is focused on the source material, creating a localized melt pool that can reach >2000°C.

In both cases, the substrate temperature is controlled independently and is typically much lower than the source temperature, often in the 100-400°C range, to promote better film quality.

Cathodic Arc Deposition (Arc-PVD)

Arc-PVD uses a high-current electric arc that moves across the source, creating small, extremely hot spots that vaporize the material into a highly ionized plasma.

While the arc itself is incredibly hot, the overall process deposits significant energy onto the substrate. Substrate temperatures are typically in the 200-500°C range to manage film stress and promote the growth of very hard, dense coatings like Titanium Nitride (TiN).

Understanding the Trade-offs

Choosing the right temperature is a balancing act. The ideal temperature from a pure physics standpoint is often constrained by practical realities.

The Substrate Limitation

This is the most common and critical constraint. The substrate dictates the maximum allowable temperature. You simply cannot heat a polymer substrate to 500°C without melting or deforming it. The PVD process parameters must be adapted to what the substrate can tolerate.

Performance vs. Cost

Achieving and maintaining high temperatures inside a vacuum chamber requires more complex hardware, longer cycle times (for heating and cooling), and higher energy consumption. A lower-temperature process is almost always faster and less expensive if it can meet the performance requirements.

Thermal Stress and Adhesion

While higher temperatures improve atomic bonding and adhesion, they can also introduce problems. If the coating and the substrate have different coefficients of thermal expansion, significant stress can build up as the part cools, potentially leading to film cracking or delamination.

Making the Right Choice for Your Goal

The optimal temperature is defined by your objective.

- If your primary focus is coating heat-sensitive materials (like plastics or electronics): Your best choice is a low-temperature process like magnetron sputtering, where substrate heating can be minimized or eliminated.

- If your primary focus is maximum hardness and density (for tooling or wear parts): You should use a higher-energy process like Arc-PVD or heated sputtering/evaporation, provided your substrate is a robust material like steel or ceramic that can handle temperatures of 300-500°C.

- If your primary focus is depositing high-purity decorative or optical films on glass or metal: Thermal or E-beam evaporation with moderate substrate heating (100-300°C) provides an excellent balance of quality and control.

Ultimately, temperature in PVD is not a byproduct; it is an active and powerful tool you must use to engineer the precise film properties your application demands.

Summary Table:

| PVD Technique | Typical Substrate Temperature Range | Key Characteristics |

|---|---|---|

| Sputtering | Near Room Temp to 500°C | Low-temperature process; ideal for heat-sensitive substrates like plastics. |

| Thermal/E-beam Evaporation | 100°C to 400°C | High source temperature (>1000°C); excellent for high-purity decorative/optical films. |

| Cathodic Arc Deposition | 200°C to 500°C | High-energy process; produces very hard, dense coatings like TiN. |

Ready to engineer the perfect PVD coating for your application?

The optimal PVD temperature is critical for achieving the film properties—like hardness, density, and adhesion—that your project demands. At KINTEK, we specialize in providing the precise lab equipment and expert support needed to master this balance, whether you're coating delicate polymers or heavy-duty tooling.

Let our experts help you select the right PVD solution. Contact KINTEL today to discuss your specific substrate, material, and performance goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition