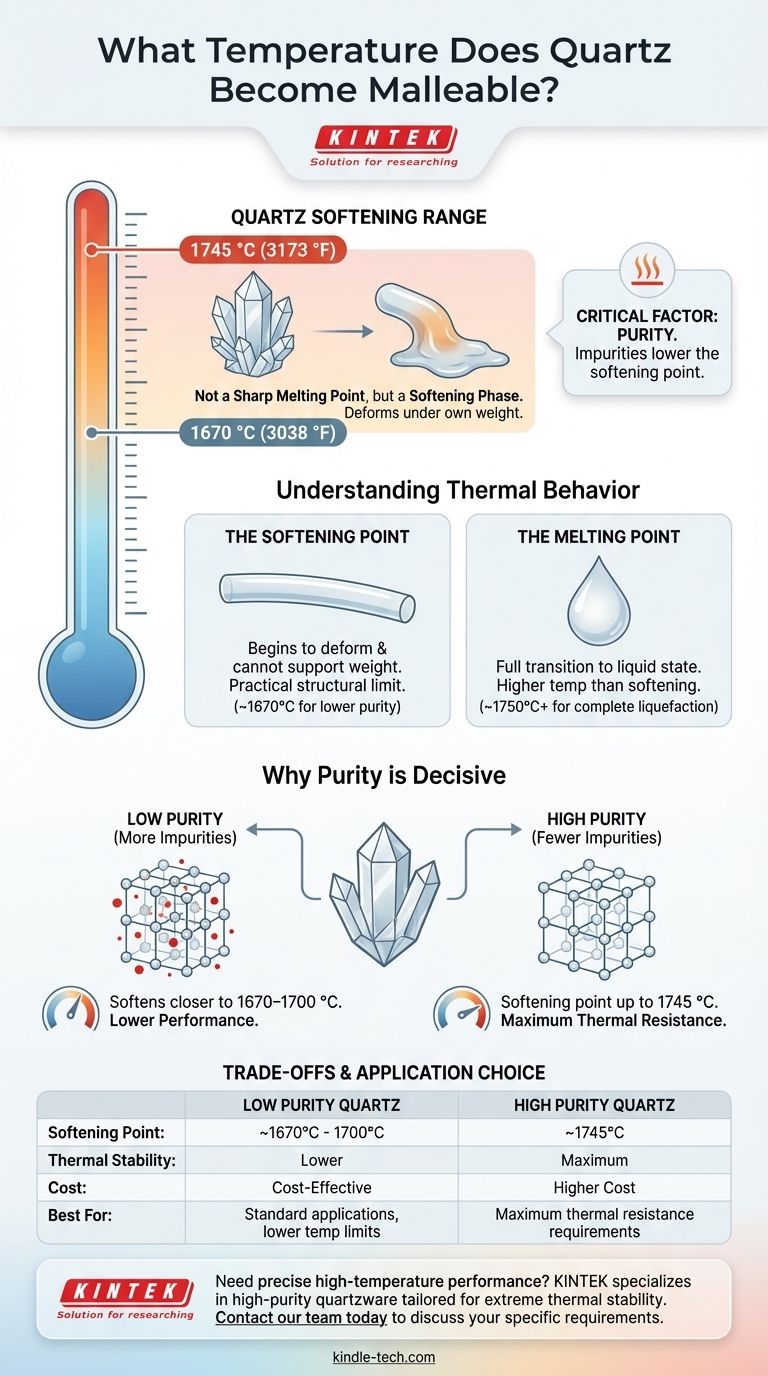

For practical purposes, quartz begins to lose its structural integrity and become malleable, or soften, at temperatures ranging from 1670 °C to 1745 °C (3038 °F to 3173 °F). This is not a single, sharp temperature but a range that is critically dependent on the purity of the material. The presence of impurities significantly lowers the temperature at which it will begin to deform.

Quartz does not become malleable like a metal; instead, it enters a softening range before it melts. The single most important factor determining this temperature is the material's purity—the fewer impurities, the higher the softening point.

Understanding Quartz's Thermal Behavior

Unlike metals, which have a distinct melting point, crystalline materials like quartz transition through a softening phase. It's crucial to distinguish between the point where it begins to deform (softening) and the point where it becomes a complete liquid (melting).

The Softening Point

The softening point is the temperature at which quartz can no longer support its own weight and begins to deform. This is the practical limit for most structural applications.

Based on material analysis, this softening temperature can be as low as 1670 °C for grades with more impurities.

The Melting Point

The melting point is the temperature at which quartz fully transitions into a liquid state. This occurs at a higher temperature than the initial softening point.

For example, even at 1750 °C, a lower-purity quartz might melt completely in 12 minutes, while a higher-purity sample could take over 80 minutes to fully liquefy.

Why Purity is the Decisive Factor

The significant variation in the softening temperature of quartz is almost entirely due to the concentration of impurities within its crystalline structure.

The Impact of Impurities

Impurities disrupt the strong silicon-oxygen bonds that give quartz its thermal stability. This disruption allows the structure to deform at lower temperatures.

Even small amounts of contaminants can have a measurable effect, making material specification essential for high-temperature work.

Different Grades, Different Performance

Commercial quartz is available in various grades. A higher-purity grade (like the "G" sample in reference studies) can have a softening point as high as 1745 °C.

In contrast, lower-purity grades (like the "B" and "C" samples) will begin to soften closer to 1670–1700 °C.

Understanding the Trade-offs

Choosing the right grade of quartz involves a direct trade-off between thermal performance and cost. This decision is fundamental to engineering and design in high-temperature environments.

High Purity vs. High Cost

Achieving high purity requires additional processing, which significantly increases the material's cost. This expense is only justified when the application demands the absolute maximum thermal resistance.

Standard Purity vs. Performance Limits

More common, less expensive grades of quartz are suitable for many applications but come with a lower performance ceiling. Using these grades requires designing for a lower maximum operating temperature to ensure a safe margin of error.

Making the Right Choice for Your Application

Your choice of quartz should be dictated by the specific thermal demands and budget of your project.

- If your primary focus is maximum thermal resistance: You must source a high-purity grade of quartz and design your system to stay well below its upper limit of ~1745 °C.

- If your primary focus is a cost-effective solution: A standard grade is acceptable, but you must consider its lower softening point of ~1670 °C as the absolute structural limit.

Ultimately, understanding the specific grade of your quartz is the only way to reliably predict its behavior at extreme temperatures.

Summary Table:

| Property | Low Purity Quartz | High Purity Quartz |

|---|---|---|

| Softening Point | ~1670°C - 1700°C | ~1745°C |

| Thermal Stability | Lower | Maximum |

| Cost | Cost-Effective | Higher Cost |

| Best For | Standard applications with lower temperature limits | Maximum thermal resistance requirements |

Need precise high-temperature performance for your lab? The right quartz grade is critical. KINTEK specializes in high-purity lab equipment and consumables, including quartzware tailored for extreme thermal stability. Our experts can help you select the ideal material to ensure safety, accuracy, and cost-efficiency in your processes. Contact our team today to discuss your specific application requirements and get a tailored solution.

Visual Guide

Related Products

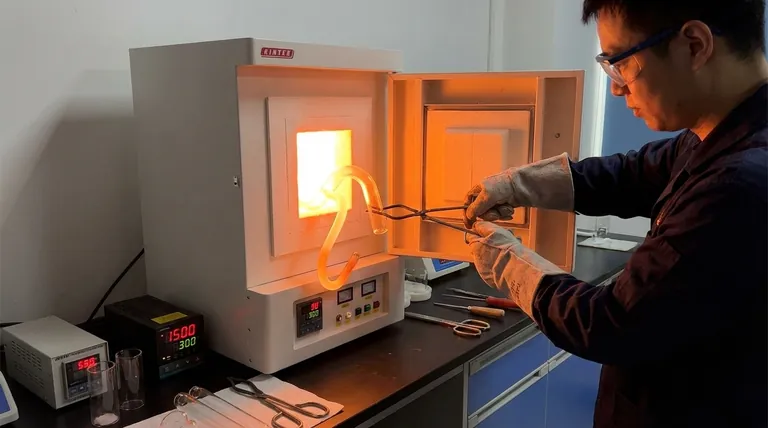

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do laboratory ovens or heating jackets influence aluminum fluoride-catalyzed glycerol acetalization efficiency?

- How does a laboratory magnetic stirrer function? Master Composite Coating Preparation with KINTEK

- Why is a high-purity nitrogen flow control device necessary for pyrolysis? Ensure Safety and Superior Product Yield

- Why is ultrasonic cleaning essential for FeCrAl coating tests? Ensure Precise High-Temperature Corrosion Data

- What are the uses of quartz glass tube? Key Applications in High-Temperature and High-Purity Processes

- Why is a vacuum pump and Buchner funnel filtration system necessary? Optimize Tungstic Acid Processing

- What is the function of a magnetic stirrer in MoO3/GO composite prep? Master Molecular Homogenization and Nucleation

- What are the technical advantages of preparing fused glass beads for XRF zirconium analysis? Achieve Peak Precision.