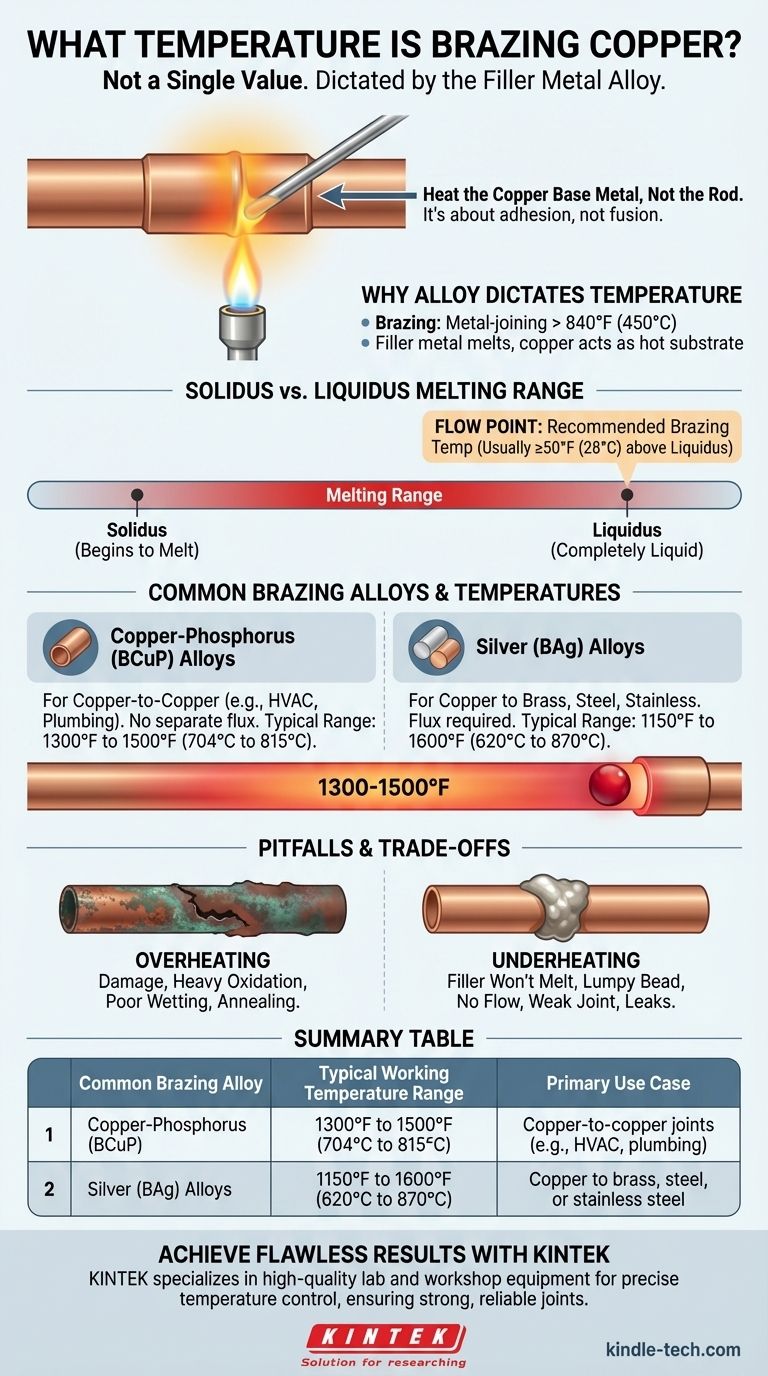

The temperature for brazing copper is not a single value; it is determined entirely by the specific filler metal alloy you are using. The process of brazing happens at temperatures above 840°F (450°C), but the exact target temperature is always a range slightly above the full melting point (liquidus) of your chosen brazing rod.

The core principle is simple: you must heat the copper hot enough for it to melt the brazing alloy, allowing the alloy to be pulled into the joint. Therefore, the correct temperature is dictated by the alloy, not the copper itself.

Why the Filler Alloy Dictates Temperature

To achieve a strong brazed joint, you must understand that brazing is a process of adhesion, not fusion. You are not melting the copper; you are using it as a hot substrate to melt a filler metal that glues the pieces together.

The Definition of Brazing

Brazing is a metal-joining process where a filler metal is heated above its melting point and distributed between two or more close-fitting parts by capillary action. The key distinction is that the filler metal has a lower melting point than the base metal (the copper).

By industry definition, brazing occurs at temperatures above 840°F (450°C). Any process below this temperature is technically considered soldering.

Solidus vs. Liquidus: The Melting Range

Brazing alloys don't melt at a single point. They melt over a temperature range.

- Solidus: The temperature at which the alloy begins to melt.

- Liquidus: The temperature at which the alloy becomes completely liquid.

For a successful braze, you must heat the base metal above the liquidus temperature of your filler alloy.

The "Flow Point" Rule of Thumb

A critical rule is to heat the copper to the alloy's "flow point," which is the recommended brazing temperature. This is typically at least 50°F (28°C) above the alloy's liquidus temperature.

This extra heat ensures the alloy remains fully liquid as it flows into the joint, creating a complete, strong, and leak-free bond. You can always find this recommended temperature range on the manufacturer's Technical Data Sheet (TDS) for the specific brazing rod.

Common Brazing Alloys and Their Temperatures

While you must always check your specific alloy's data sheet, most copper brazing falls into two common categories.

Copper-Phosphorus (BCuP) Alloys

These are the most common alloys for joining copper to copper, especially in HVAC and plumbing. The phosphorus acts as a fluxing agent, so no separate flux is needed for copper-to-copper joints.

Their typical working temperature range is 1300°F to 1500°F (704°C to 815°C).

Silver (BAg) Alloys

Often called "silver solder" (though technically a brazing alloy), these contain silver and are used for higher-strength joints or for joining copper to other metals like brass, steel, or stainless steel. A separate flux is almost always required.

Their working temperatures vary widely based on silver content but are often in the range of 1150°F to 1600°F (620°C to 870°C).

Understanding the Trade-offs and Pitfalls

Achieving the correct temperature is a balancing act. Both too much and too little heat will compromise the integrity of your joint.

The Danger of Overheating

If you apply too much heat, you can damage the copper. The surface will oxidize heavily, which can prevent the filler alloy from wetting and bonding properly.

Extreme overheating can also anneal the copper, making it soft and weak, or in the worst case, even melt the copper pipe itself.

The Problem with Underheating

Insufficient heat is the most common cause of failed braze joints. If the copper is not hot enough, the filler alloy will not melt and flow correctly via capillary action.

This results in a thick, lumpy bead that sits on the surface of the joint instead of being drawn inside. The joint will have no strength and will certainly leak.

The Critical Role of Heat Control

Remember to heat the base metal, not the filler rod. The goal is to bring the copper pipe and fitting up to temperature. You then touch the rod to the hot joint, and the heat from the copper should melt the alloy instantly, pulling it into the gap.

Making the Right Choice for Your Goal

Your success depends on matching your heat, alloy, and technique to the specific job.

- If your primary focus is a standard copper-to-copper joint (like in HVAC): Use a BCuP alloy and aim for a cherry-red glow on the copper, which corresponds to the 1300-1500°F range.

- If your primary focus is joining copper to brass or steel: Select a BAg silver alloy with the appropriate flux and consult its data sheet for the precise working temperature.

- If your primary focus is absolute joint integrity: Always locate the Technical Data Sheet for your specific brazing alloy and follow its recommended temperature range precisely.

Ultimately, knowing your material is the key to mastering the brazing process.

Summary Table:

| Common Brazing Alloy | Typical Working Temperature Range | Primary Use Case |

|---|---|---|

| Copper-Phosphorus (BCuP) | 1300°F to 1500°F (704°C to 815°C) | Copper-to-copper joints (e.g., HVAC, plumbing) |

| Silver (BAg) Alloys | 1150°F to 1600°F (620°C to 870°C) | Copper to brass, steel, or stainless steel |

Achieve Flawless Brazing Results with the Right Equipment

Mastering copper brazing requires precise temperature control. Whether you're working in HVAC, plumbing, or advanced manufacturing, having the right tools is essential for creating strong, reliable joints.

KINTEK specializes in high-quality lab and workshop equipment, including temperature-controlled furnaces and heating solutions that provide the uniform, consistent heat necessary for perfect brazing outcomes. Our products help technicians and engineers avoid the pitfalls of overheating and underheating, ensuring joint integrity every time.

Let us help you elevate your brazing process. Contact our experts today to find the perfect heating solution for your specific alloy and application needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease