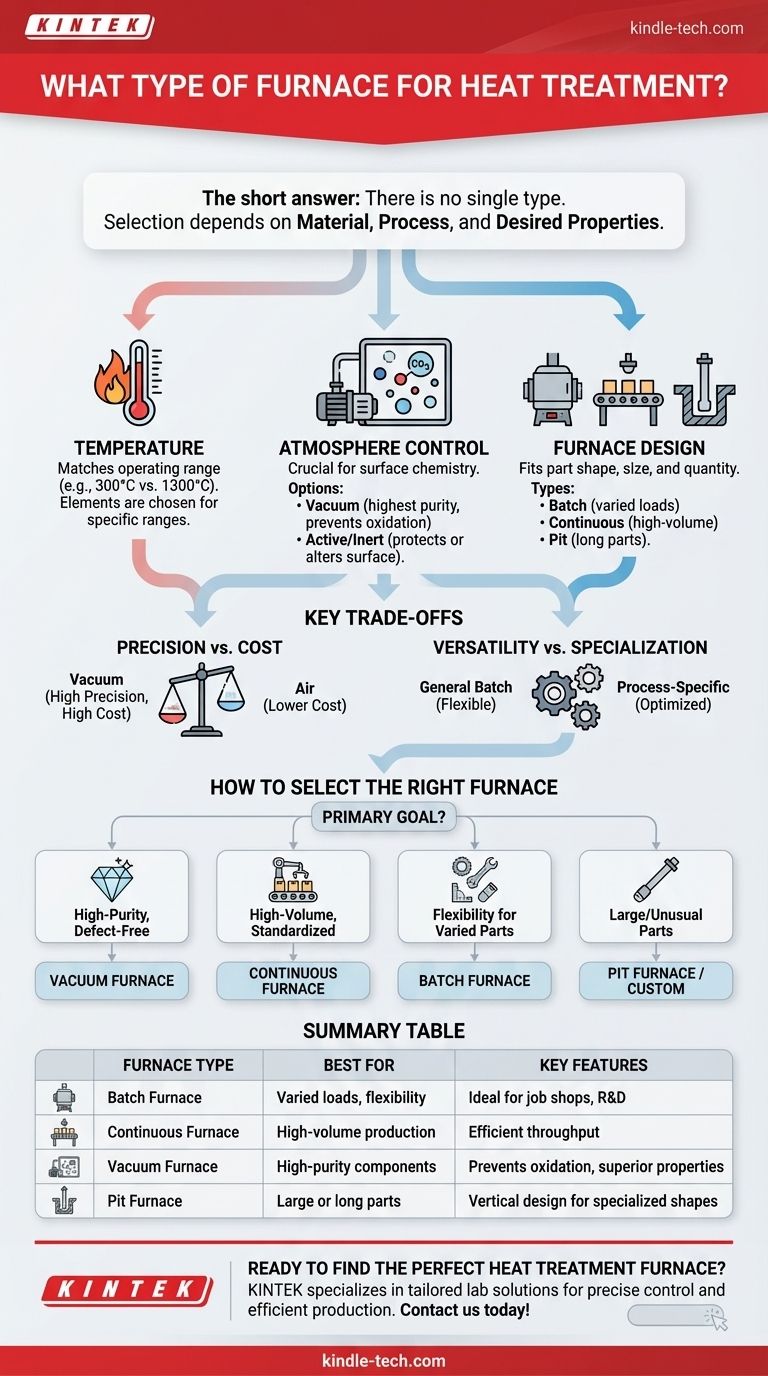

The short answer is there is no single type of furnace for heat treatment. Instead, the furnace is selected based on the specific material, the required process, and the desired final properties of the component. The most common categories include batch furnaces for varied loads, continuous furnaces for high-volume production, and vacuum furnaces for processes requiring pristine atmospheric control.

The critical insight is that a heat treatment furnace is not just a heater; it is a highly controlled environment. The right choice is always the furnace that can precisely manage the temperature, atmosphere, and physical handling required by your specific application.

The Core Factors Driving Furnace Selection

Choosing a furnace involves matching its capabilities to the metallurgical requirements of your process. The decision is driven by three primary factors: the required temperature, the necessary atmospheric conditions, and the physical design of the furnace.

The Role of Temperature

The design of a furnace is fundamentally tied to its operating temperature range. Different processes like tempering, annealing, or sintering occur at vastly different temperatures.

A furnace engineered for very high temperatures (e.g., 1300°C) may not provide the precise control or efficiency needed for a low-temperature process (e.g., 300°C).

The heating elements—such as resistance wires, silicon molybdenum rods, or graphite—are chosen specifically for these temperature ranges, directly influencing the furnace's capabilities.

The Critical Impact of Atmosphere Control

The atmosphere inside the furnace can dramatically alter the surface of the material being treated. The choice of atmosphere is one of the most important decisions in heat treatment.

Vacuum furnaces provide the highest level of control. By removing atmospheric gases, they prevent oxidation, decarburization, and other contamination, resulting in a clean, high-purity end product with superior mechanical properties.

Other processes may require a specific active or inert atmosphere. The right choice is determined by the material, the product's design, and whether the goal is simply to protect the component or to intentionally alter its surface chemistry (as in carburizing).

Matching Furnace Design to the Material

The physical shape, size, and quantity of the parts being treated dictate the mechanical design of the furnace.

Batch-type furnaces, such as chamber or bell furnaces, are ideal for processing single parts or small lots with varied treatment cycles.

Continuous furnaces, like rotary hearth models, are used in high-volume forging and production environments where parts are constantly charged and discharged.

Pit furnaces are a type of vertical furnace often used for treating long parts like shafts, while vertical tube furnaces may be preferred for specialized lab tests like quenching.

Understanding the Key Trade-offs

Selecting a furnace always involves balancing competing priorities. Understanding these trade-offs is essential for making an informed decision.

Precision vs. Cost

A vacuum furnace offers unparalleled precision and a pristine processing environment, but it represents a significant capital investment.

For applications where surface oxidation is not a critical concern, a simpler and less expensive air-atmosphere furnace may be entirely sufficient, drastically lowering costs.

Versatility vs. Specialization

A general-purpose batch furnace can handle a wide variety of parts and processes, offering excellent flexibility for a job shop or R&D lab.

However, a furnace designed for a specific process, like bright annealing or vacuum brazing, will always deliver better performance, consistency, and efficiency for that particular task.

How to Select the Right Furnace for Your Application

Your final choice should be guided by the primary goal of your heat treatment process.

- If your primary focus is high-purity, defect-free components: A vacuum furnace is essential to eliminate oxidation and ensure superior material properties.

- If your primary focus is high-volume, standardized production: A continuous furnace design will provide the efficiency and throughput you require.

- If your primary focus is flexibility for varied parts and processes: A batch-type chamber furnace offers the operational versatility needed for diverse workloads.

- If your primary focus is treating large or unusually shaped parts: A specialized configuration like a pit furnace or custom-designed in/out furnace will be necessary.

Ultimately, the right furnace is the one that reliably delivers the precise thermal and atmospheric environment your specific material and process demand.

Summary Table:

| Furnace Type | Best For | Key Features |

|---|---|---|

| Batch Furnace | Varied loads, flexibility | Ideal for job shops, R&D labs; handles different parts and cycles |

| Continuous Furnace | High-volume production | Efficient throughput for standardized parts |

| Vacuum Furnace | High-purity, defect-free components | Prevents oxidation, ensures superior material properties |

| Pit Furnace | Large or long parts (e.g., shafts) | Vertical design for specialized shapes |

Ready to find the perfect heat treatment furnace for your lab? At KINTEK, we specialize in lab equipment and consumables, providing tailored solutions that ensure precise temperature control, optimal atmosphere management, and efficient production. Whether you need a versatile batch furnace for R&D or a high-purity vacuum system for critical components, our experts will help you select the right equipment to enhance your lab's performance. Contact us today to discuss your specific requirements and discover how KINTEK can support your laboratory needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation