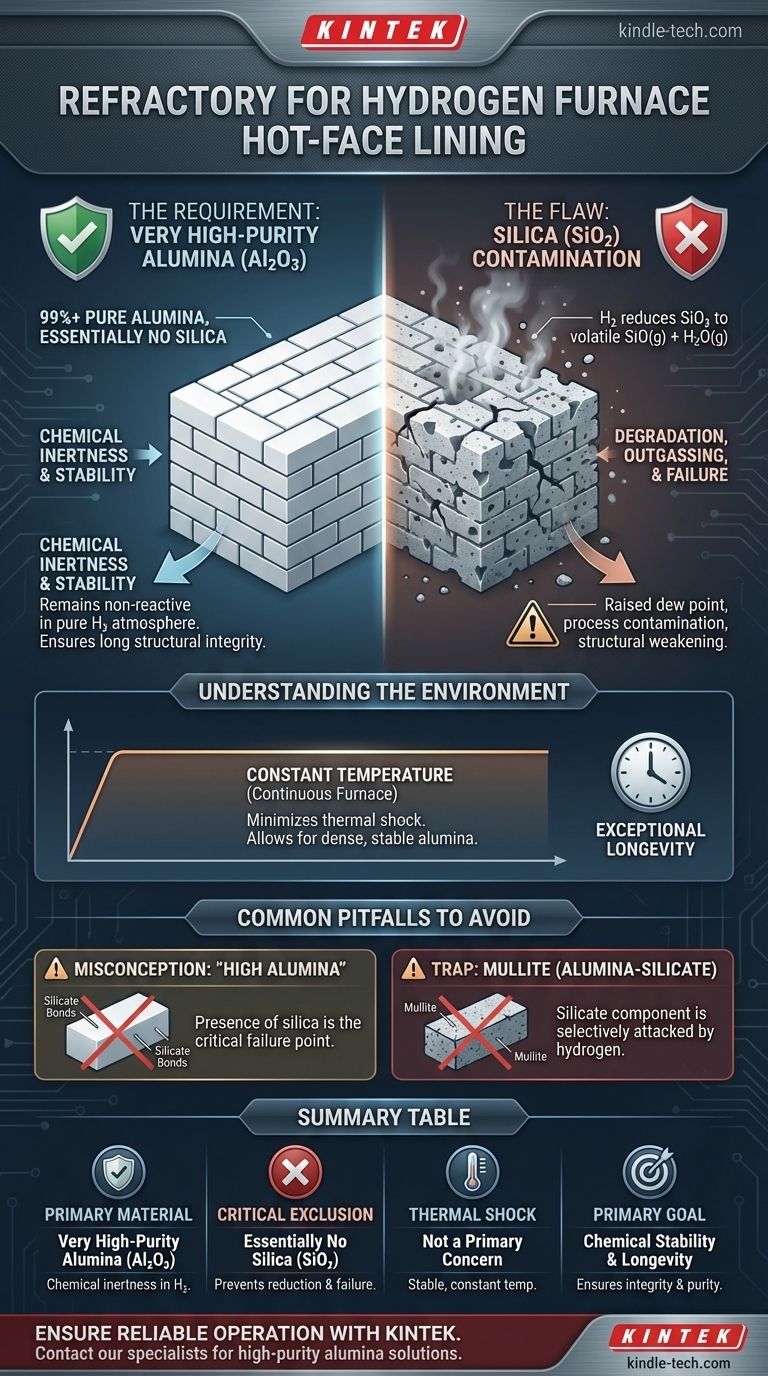

For the hot-face lining in the hot zone of a continuous hydrogen furnace, the definitive requirement is a very high-purity alumina refractory with essentially no silica. This specific material choice is driven by the unique chemical environment created by high-temperature hydrogen, where material stability is paramount.

The core principle is not heat resistance alone, but chemical inertness. Standard refractories containing silica will chemically react with hot hydrogen, leading to the rapid degradation of the furnace lining and contamination of the process atmosphere.

The Chemistry Behind the Requirement

The selection of a refractory for a hydrogen furnace is a lesson in high-temperature chemistry. The wrong choice doesn't just wear out; it actively disintegrates.

Why High-Purity Alumina (Al₂O₃) is Essential

High-purity aluminum oxide (alumina) is chosen because it is one of the most stable oxides available.

At the operating temperatures of these furnaces, it remains almost entirely non-reactive in a pure hydrogen atmosphere. This chemical stability ensures the structural integrity of the furnace lining over long periods.

The Critical Flaw of Silica (SiO₂)

Silica is a common component in many high-temperature refractories, but it is a point of failure in a hydrogen environment.

At elevated temperatures, hydrogen gas will actively reduce silica (SiO₂) to form volatile silicon monoxide (SiO) gas and water vapor (H₂O). This reaction physically removes material from the refractory brick, weakening its structure.

Consequences of Silica Contamination

The presence of even small amounts of silica in the hot zone lining leads to cascading problems.

The outgassing of water vapor raises the dew point within the furnace, which can be detrimental to the sensitive process being run. Furthermore, the degradation of the refractory compromises the furnace's structural integrity, leading to premature and costly failure.

Understanding the Operating Environment

The design of a continuous furnace creates a unique set of conditions that influence the refractory choice.

Constant Temperature Minimizes Thermal Shock

In the hot zone of a continuous furnace, the temperature is held at a constant setpoint for extended periods.

Because the refractory is not subjected to rapid heating and cooling cycles, thermal shock resistance is not a primary design concern. This allows for the use of dense, high-purity alumina materials that might otherwise be too brittle for applications with significant temperature fluctuation.

Stability Translates to Longevity

The combination of a chemically inert material (high-purity alumina) and a stable operating temperature results in exceptional service life.

A correctly specified and installed hot-face lining can last for many years without significant degradation, making it a highly reliable and cost-effective long-term solution.

Common Pitfalls to Avoid

A misunderstanding of the underlying chemistry is the most common source of error in refractory selection for this application.

The "High Alumina" Misconception

Simply specifying a "high alumina" refractory is insufficient and can be misleading. Many refractories classified as high-alumina still use silicate bonds or contain significant silica content.

It is the near-total absence of silica that is the critical specification, not just a high percentage of alumina.

The Alumina-Silicate Trap

Refractories such as mullite (an alumina-silicate) are excellent for many high-temperature applications but are unsuitable for the hot zone of a hydrogen furnace.

The "silicate" component will be selectively attacked by the hydrogen, leading to the same failure modes described above. Always prioritize purity over other properties in this specific zone.

Making the Right Choice for Your Goal

To ensure operational success, your refractory specification must be driven by the chemical demands of the hydrogen atmosphere.

- If your primary focus is maximum furnace life and process purity: You must insist on a refractory specification of 99%+ pure alumina with the lowest achievable silica content.

- If your primary focus is reliability and avoiding unscheduled downtime: Prioritize the chemical compatibility with hydrogen above all other material properties, including cost or thermal shock resistance.

- If you are evaluating an existing furnace or a repair: A key diagnostic step is to analyze the refractory composition for silica, as its presence is a direct indicator of potential failure.

Ultimately, selecting the correct refractory is based on a clear understanding that in a hydrogen furnace, the atmosphere itself is the most corrosive element.

Summary Table:

| Key Property | Requirement | Why It Matters |

|---|---|---|

| Primary Material | Very High-Purity Alumina (Al₂O₃) | Provides chemical inertness in a hydrogen atmosphere. |

| Critical Exclusion | Essentially No Silica (SiO₂) | Prevents reduction by hydrogen, which causes volatile gas formation and lining failure. |

| Thermal Shock Resistance | Not a Primary Concern | The continuous furnace operates at a stable, constant temperature. |

| Primary Goal | Chemical Stability & Longevity | Ensures furnace integrity, process purity, and avoids costly downtime. |

Ensure your hydrogen furnace operates reliably for years. The wrong refractory choice leads to rapid degradation and process contamination. KINTEK specializes in high-performance lab equipment and consumables, including high-purity alumina refractories designed specifically for demanding environments like hydrogen furnaces. Our experts can help you select the right materials to protect your investment and maintain process integrity.

Contact our specialists today for a consultation on the ideal refractory solution for your application.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation