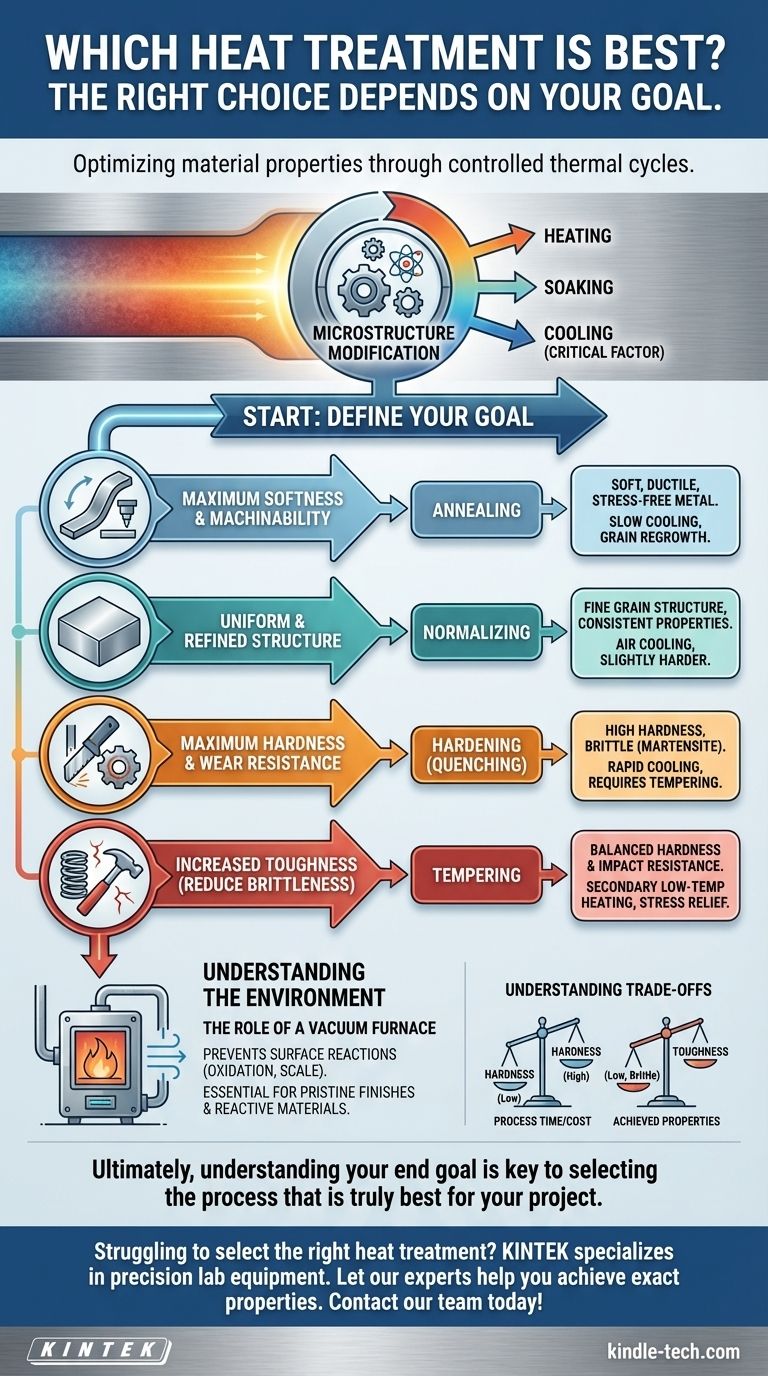

The "best" heat treatment is the one that precisely modifies a metal's properties to meet the demands of a specific application. There is no universal best; the optimal choice depends entirely on whether your goal is to make the material softer for machining, harder for wear resistance, or tougher to prevent fracture. Selecting the right process requires understanding your desired outcome first.

The core principle of heat treatment is not about finding a single "best" method, but about choosing the specific thermal cycle—heating, holding, and cooling—that intentionally alters the metal's internal microstructure to achieve a desired set of mechanical properties like hardness, toughness, or ductility.

The Purpose of Heat Treatment: Changing Properties

Heat treatment is the controlled application of heat to alter a material's internal structure, and by extension, its physical and mechanical properties. It doesn't change the metal's shape, but it fundamentally changes its behavior.

The Role of Microstructure

At a microscopic level, metals are composed of crystalline grains. The size, shape, and composition of these grains—collectively known as the microstructure—determine how the metal performs. Heat treatment is the tool used to manipulate this microstructure.

The Three Critical Stages

Every heat treatment process consists of three stages:

- Heating: Raising the material to a specific temperature at a controlled rate.

- Soaking: Holding the material at that temperature for a set duration to ensure a uniform internal change.

- Cooling: Cooling the material back to room temperature at a specific, controlled rate. The cooling rate is often the most critical factor in determining the final properties.

Common Goals and Their Corresponding Treatments

The "best" treatment is defined by your goal. Here are the most common objectives and the processes used to achieve them.

Goal: Maximum Softness and Machinability

To achieve the softest, most ductile, and most easily machinable state, the primary process is annealing. The material is heated and then cooled very slowly, often by leaving it inside the insulated furnace to cool overnight.

This slow cooling allows the internal crystal grains to regrow into a large, uniform, and low-stress state. This relieves internal stresses from previous manufacturing steps and makes the metal easy to form or machine.

Goal: A Uniform and Refined Structure

For creating a more uniform and predictable material, the process is normalizing. Like annealing, it involves heating the metal, but the cooling is done in open air, which is significantly faster.

This faster cooling creates a finer, more refined grain structure. The resulting material is slightly harder and stronger than an annealed one but is more uniform and consistent, making it a good "default" state before subsequent hardening operations.

Goal: Maximum Hardness and Wear Resistance

When the goal is to make steel as hard as possible, the process is hardening, also known as quenching. This involves heating the steel and then cooling it extremely rapidly by plunging it into a medium like water, oil, or forced air.

This rapid quench "traps" the microstructure in a very hard, brittle state called martensite. The resulting part has excellent wear resistance but is too brittle for most applications without a follow-up treatment.

Goal: Increased Toughness (Reducing Brittleness)

A hardened part is often too brittle to be useful. Tempering is a secondary, low-temperature heat treatment performed immediately after quenching. It reduces some of the extreme hardness and relieves the internal stresses created by quenching.

The result is a significant increase in toughness—the ability to absorb impact without fracturing—at the expense of a minor reduction in hardness. The final balance of hardness and toughness is precisely controlled by the tempering temperature and time.

Understanding the Process Environment

Beyond the heating and cooling cycle, the environment in which the treatment occurs is also a key consideration.

The Role of a Vacuum Furnace

Vacuum heat treatment is not a type of treatment itself, but a method for performing a treatment like annealing or hardening. The process is run inside a sealed chamber with the air removed.

The primary benefit of a vacuum is that it prevents surface reactions. Without oxygen, the metal part does not form scale (oxide layers), keeping its surface clean and bright. This eliminates the need for costly post-treatment cleaning.

When is a Vacuum Necessary?

A vacuum environment is critical for materials that react readily with air, such as titanium or high-alloy tool steels. It is also chosen when the final surface finish is a primary concern, as it delivers a part with a pristine, unaltered surface. The reference's point on energy efficiency is also valid, as modern vacuum furnaces are highly optimized.

Understanding the Trade-offs

Choosing a heat treatment always involves balancing competing properties and costs.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off. A material that is extremely hard is almost always brittle. A material that is very tough (not brittle) is typically softer. The goal of hardening followed by tempering is to find the ideal balance for the specific application.

Risk of Distortion and Cracking

The rapid cooling involved in hardening induces immense internal stress. This stress can cause parts, especially those with complex shapes or sharp corners, to warp, distort, or even crack during the process. Slowing the quench rate reduces this risk but also reduces the achievable hardness.

Process Time and Cost

Annealing requires a very long cooling cycle, tying up furnace capacity and increasing costs. Normalizing is faster and generally less expensive. Hardening and tempering is a two-step process that requires careful control, adding complexity and cost.

Making the Right Choice for Your Goal

To select the best process, you must first define your primary objective.

- If your primary focus is making a metal as soft as possible for extensive machining: Annealing is the correct choice because its slow cooling rate produces the most ductile and stress-free structure.

- If your primary focus is creating a uniform, reliable material before further processing: Normalizing provides a refined grain structure and consistent properties at a reasonable cost.

- If your primary focus is achieving high hardness for wear resistance (e.g., for a cutting tool): Hardening (quenching) followed by a specific tempering cycle is the only way to achieve this.

- If your primary focus is preserving a perfect, clean surface on the final part: Performing the selected heat treatment within a vacuum furnace is the ideal method.

Ultimately, understanding your end goal is the key to unlocking the power of heat treatment and selecting the process that is truly best for your project.

Summary Table:

| Goal | Recommended Process | Key Outcome |

|---|---|---|

| Maximum Softness & Machinability | Annealing | Soft, ductile, stress-free metal |

| Uniform & Refined Structure | Normalizing | Fine grain structure, consistent properties |

| Maximum Hardness & Wear Resistance | Hardening (Quenching) | High hardness, brittle state (requires tempering) |

| Increased Toughness (Reduce Brittleness) | Tempering | Balanced hardness and impact resistance |

| Pristine Surface Finish | Vacuum Heat Treatment | Clean, scale-free surface, no oxidation |

Struggling to select the right heat treatment for your lab materials? KINTEK specializes in precision lab equipment, including advanced furnaces for annealing, hardening, and vacuum heat treatment processes. Our experts can help you achieve the exact material properties you need—whether it's superior hardness, enhanced toughness, or a flawless surface finish. Contact our team today to discuss your specific application and discover how KINTEK's solutions can optimize your lab's efficiency and results.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What industry is annealing used in? From Automotive to Medical Devices

- What is the purpose of a heat treatment furnace? Unlock Your Material's Full Potential

- What is the function of the heat treatment process? Tailor Material Properties for Your Application

- What are the advantages of heat treatment processes explain? Enhance Material Strength and Performance

- Which type of brazing is done in a vacuum? Achieve Clean, Strong Joints with Vacuum Brazing

- What role does a high-vacuum high-temperature furnace play for AISI 316? Ensure Pure Microstructural Standardization

- How does heat affect tensile strength? Understand the Strength-Ductility Trade-Off

- What is the significance of using high-vacuum heat treatment furnaces and rapid quenching for zirconium alloys?