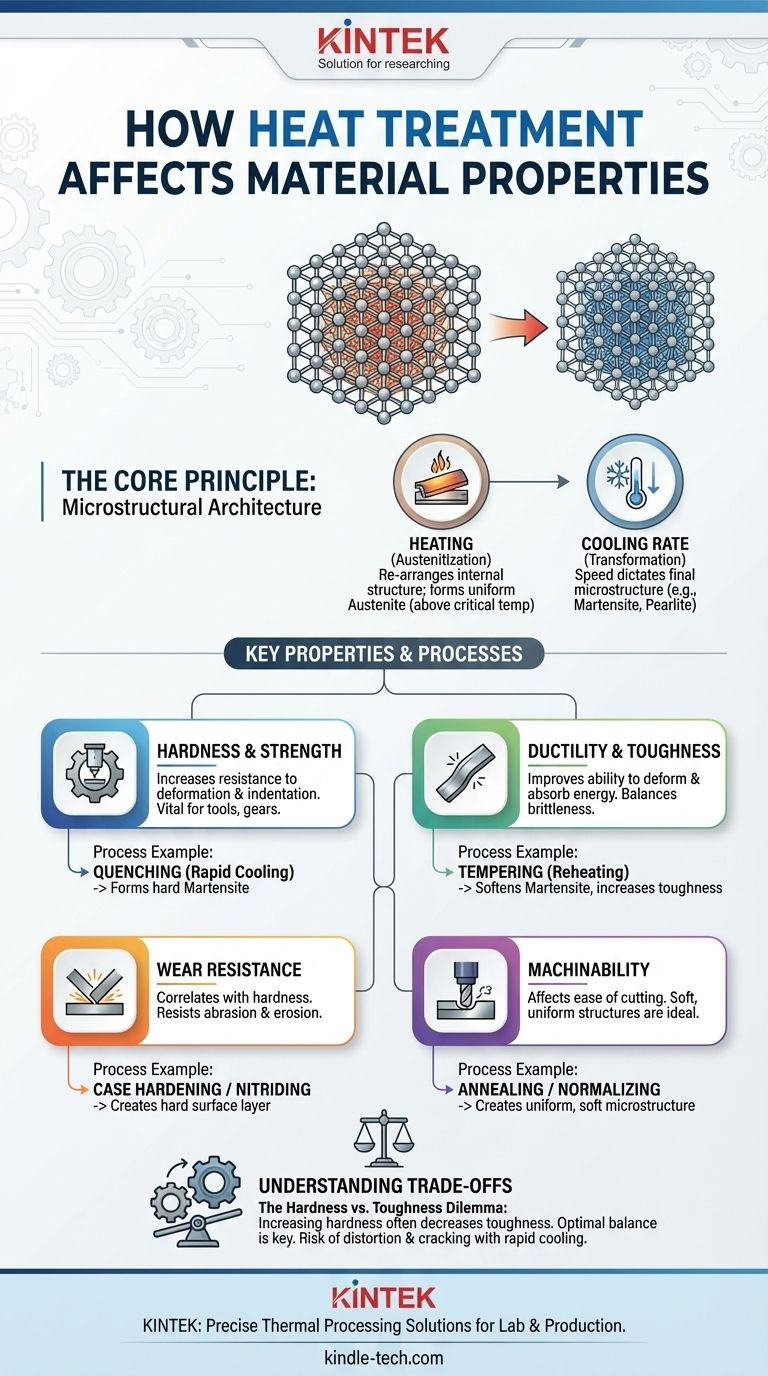

In short, heat treatment profoundly affects a material's mechanical properties. The most significant changes occur in a material's hardness, strength, ductility, toughness, and wear resistance. These changes are not arbitrary; they are the direct result of controlled heating and cooling cycles that manipulate the material's internal microstructure.

The central principle to understand is that heat treatment does not change the chemical composition of a material. Instead, it re-arranges the material’s microscopic internal structure—its crystal lattice and grain boundaries—to achieve specific, desirable engineering properties.

How Heat Treatment Fundamentally Works

Heat treatment is best understood as a form of "microstructural architecture." You are taking the material's existing atomic structure, dissolving it with heat, and then re-forming it into a new structure by controlling the cooling rate.

The Role of Heating (Austenitization)

For carbon steels, the process begins by heating the material above a critical temperature (typically between 723°C and 912°C).

At this temperature, the standard crystal structure of iron transforms into a phase called austenite. Austenite has a unique ability to dissolve a significant amount of carbon into its structure, creating a uniform, solid solution.

The Role of Cooling Rate (Transformation)

The properties of the final material are determined entirely by what happens to the austenite as it cools. The speed of cooling dictates the final microstructure.

- Slow Cooling (e.g., in air or a furnace): This gives the carbon atoms time to diffuse out of the iron lattice and form soft, ductile structures like pearlite and ferrite. This is the basis for processes like annealing.

- Rapid Cooling (e.g., quenching in water or oil): This cools the material so quickly that the carbon atoms are trapped within the iron lattice. This creates a highly strained and distorted structure called martensite, which is extremely hard and brittle.

The Specific Properties Affected

The microstructures created during cooling directly govern the final mechanical properties of the component.

Hardness and Strength

This is the most common goal of heat treatment. The formation of hard microstructures like martensite or bainite dramatically increases the material's resistance to indentation and deformation. This is why tools, bearings, and gears are almost always heat-treated.

Ductility and Toughness

Ductility (the ability to deform without fracturing) and toughness (the ability to absorb energy before fracturing) are often inversely related to hardness.

A fully hardened, martensitic steel is very brittle. A process called tempering—reheating the hardened steel to a lower temperature—is used to slightly soften the martensite, which significantly increases its toughness and ductility.

Wear Resistance

Wear resistance is directly correlated with hardness. A harder surface is better able to resist abrasion, erosion, and adhesion from contact with other surfaces. Heat treatments like case hardening or nitriding are specifically designed to create an extremely hard surface layer.

Machinability

A material's microstructure also affects how easily it can be cut. Very hard materials are difficult to machine, while very soft materials can be "gummy" and produce a poor surface finish.

Processes like annealing or normalizing are used to create a uniform, soft microstructure that is ideal for machining operations.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it involves a series of critical engineering compromises.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a material's hardness and strength, you almost always decrease its toughness, making it more brittle. The goal of a process like quenching and tempering is to find the optimal balance point for a specific application.

Risk of Distortion and Cracking

Rapidly cooling a part from a high temperature induces immense internal stress. This stress can cause the part to warp, change dimensions, or, in severe cases, crack. Controlling cooling rates and part geometry is critical to avoiding these failures.

Material Limitations

Not all materials respond to heat treatment. The effect is highly dependent on the alloy's chemical composition. For steels, the carbon content is the single most important factor determining its "hardenability"—its ability to form martensite and become hard. Low-carbon steels cannot be significantly hardened by quenching and tempering alone.

Making the Right Choice for Your Goal

The specific heat treatment process is always chosen to achieve a desired outcome.

- If your primary focus is maximum hardness and wear resistance: Use a process involving a rapid quench to form martensite, such as through-hardening or case hardening.

- If your primary focus is improving machinability or formability: Use annealing to create the softest possible microstructure.

- If your primary focus is balancing strength with fracture resistance: Use quenching followed by tempering to achieve a tough, tempered martensite structure.

- If your primary focus is relieving internal stresses from welding or forming: Use a low-temperature stress relief process that does not significantly alter the core mechanical properties.

Ultimately, heat treatment empowers you to take a standard material and precisely tailor its properties to meet the demands of its specific application.

Summary Table:

| Property Affected | Effect of Heat Treatment | Common Process Example |

|---|---|---|

| Hardness & Strength | Dramatically increases | Quenching (Rapid Cooling) |

| Ductility & Toughness | Increases (after tempering) | Tempering |

| Wear Resistance | Significantly improves | Case Hardening, Nitriding |

| Machinability | Improves for easier cutting | Annealing, Normalizing |

Need to precisely tailor the properties of your materials? The right heat treatment process is key to achieving the perfect balance of hardness, strength, and toughness for your specific application. At KINTEK, we specialize in providing the high-performance lab equipment and consumables necessary for precise thermal processing. Whether you're developing new alloys or optimizing production, our solutions help you achieve reliable, repeatable results.

Contact our experts today to discuss how we can support your laboratory's material science and heat treatment challenges.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the applications of graphite material? Leveraging Extreme Heat and Precision for Industrial Processes

- Why graphite is used in furnace? Achieve Superior Heat Treatment & Energy Efficiency

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- What temperature can graphite withstand? Unlocking Its Extreme Heat Potential

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments