For most heavy-duty industrial applications, the hydraulic press is the definitive choice. Its ability to generate and sustain immense, controllable force throughout the entire length of its stroke makes it uniquely suited for the most demanding forming, pressing, and assembly tasks where raw power and precision are paramount.

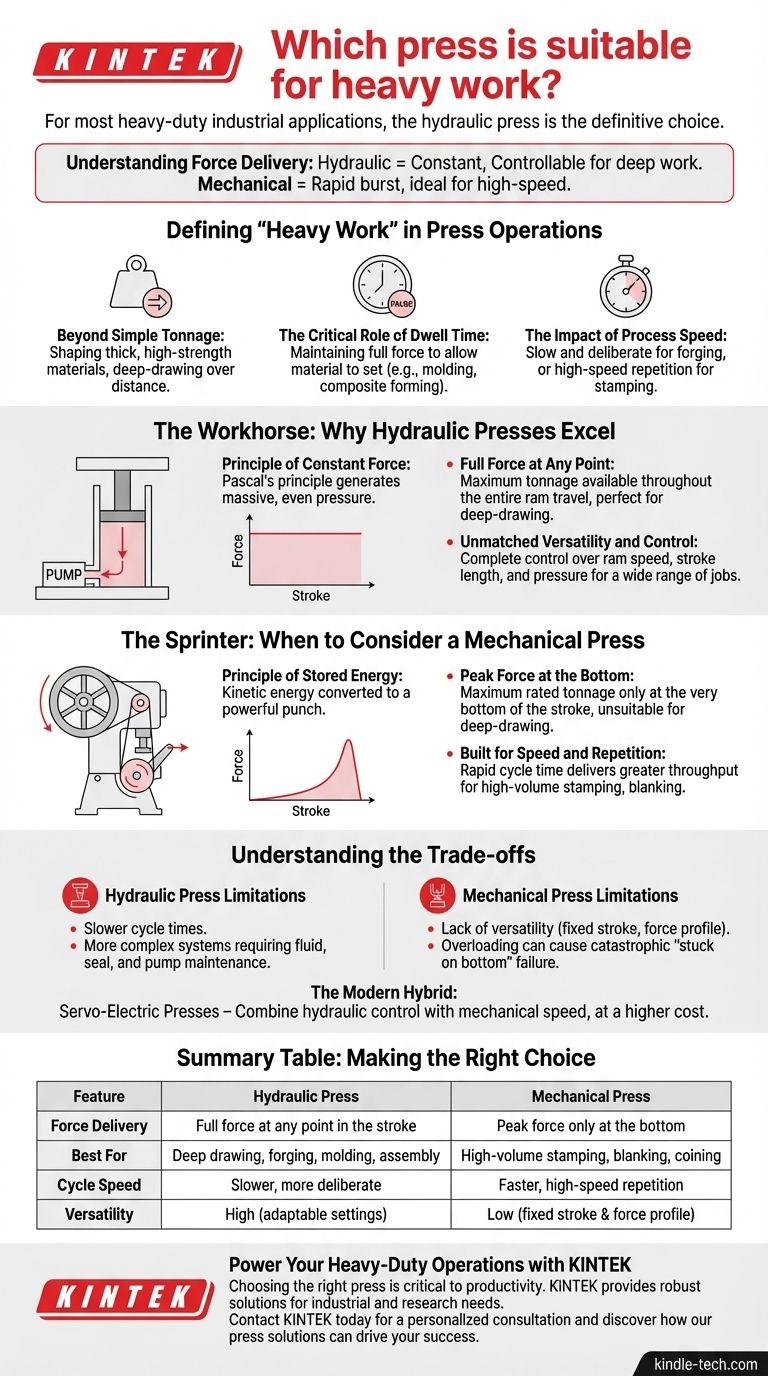

Choosing a press for heavy work is about more than just finding the highest tonnage rating. The critical factor is understanding how that force is delivered. A hydraulic press provides constant, controllable force for deep work, while a mechanical press delivers a rapid burst of energy ideal for high-speed production.

Defining "Heavy Work" in Press Operations

To select the right machine, we must first clarify what "heavy work" truly means. It's a combination of force, material resistance, and the specific process you need to perform.

Beyond Simple Tonnage

While a high tonnage rating is essential, "heavy work" often involves shaping thick, high-strength materials like steel plate or performing deep-drawing operations. These tasks require the force to be applied consistently over a significant distance, not just at a single point.

The Critical Role of Dwell Time

Dwell time is the duration the press can maintain its full force at the bottom of the stroke. Many heavy-duty applications, such as plastic molding or composite forming, require the ram to "dwell" under full pressure to allow the material to set. This is a capability where hydraulic presses naturally excel.

The Impact of Process Speed

Is your goal a single, powerful forming operation or thousands of repetitive hits per hour? Heavy forging is a slow, deliberate process, while heavy-gauge stamping is a high-speed one. The required cycle time is a major factor in your decision.

The Workhorse: Why Hydraulic Presses Excel

The hydraulic press is the default solution for heavy, force-intensive work due to its fundamental operating principle.

The Principle of Constant Force

A hydraulic press uses a pump to move incompressible fluid into a cylinder, acting on a piston. Based on Pascal's principle, this generates massive, even pressure. The force is directly proportional to the fluid pressure and the piston area, allowing for precise control.

Full Force at Any Point in the Stroke

This is the single most important advantage of a hydraulic press. It can deliver its maximum rated tonnage at any point in the ram's travel. Whether you are just starting to form a part or are at the very bottom of the stroke, the full force is available, making it perfect for deep-drawing and forming.

Unmatched Versatility and Control

Hydraulic systems provide complete control over ram speed, stroke length, and pressure. This adaptability allows a single hydraulic press to handle a vast range of heavy jobs, from forging and molding to straightening thick beams and pressing large assemblies together.

The Sprinter: When to Consider a Mechanical Press

While hydraulic presses are more versatile for heavy work, high-tonnage mechanical presses dominate certain heavy-duty applications.

The Principle of Stored Energy

A mechanical press uses a large, spinning flywheel to store kinetic energy. When the clutch is engaged, a crank mechanism converts this rotational energy into the linear motion of the ram, delivering a powerful punch.

Peak Force at the Bottom

Unlike a hydraulic press, a mechanical press only achieves its maximum rated tonnage at the very bottom of its stroke. The force available diminishes significantly as you move up the stroke, making it unsuitable for deep-drawing.

Built for Speed and Repetition

The primary advantage of a mechanical press is speed. For high-volume applications like heavy-gauge blanking, stamping, and coining, its rapid cycle time delivers far greater throughput and efficiency than a hydraulic press.

Understanding the Trade-offs

No machine is perfect for every job. Objectively weighing the limitations of each type is critical for making a sound investment.

Hydraulic Press Limitations

The main trade-off is slower cycle times compared to mechanical presses. They are also more complex systems that require regular maintenance of the hydraulic fluid, seals, and pumps to prevent leaks and ensure consistent performance.

Mechanical Press Limitations

The biggest drawback is the lack of versatility. The fixed stroke and the delivery of force only at the bottom make it a specialized tool. Furthermore, overloading a mechanical press can cause it to get "stuck on bottom," a critical failure that can be catastrophic and expensive to repair.

The Modern Hybrid: Servo-Electric Presses

Servo-electric presses are a newer technology that uses powerful servo motors to drive the ram. They combine the programmability and full-stroke force profile of a hydraulic press with the speed and energy efficiency of a mechanical press, but they come at a significantly higher initial cost.

Making the Right Choice for Your Application

Your final decision must be guided by the specific nature of the work you perform most often.

- If your primary focus is deep drawing, forging, molding, or assembling large components: A hydraulic press is the correct choice for its ability to deliver sustained, controllable force throughout the stroke.

- If your primary focus is high-volume stamping, blanking, or coining of thick materials: A high-tonnage mechanical press will provide the speed and efficiency you need for mass production.

- If your primary focus requires a blend of high speed and full-stroke force control for precision forming: Investigate a servo-electric press, but be prepared for a higher capital investment.

Understanding how each press generates and applies its force is the key to selecting the right tool to power your work.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Delivery | Full force at any point in the stroke | Peak force only at the bottom of the stroke |

| Best For | Deep drawing, forging, molding, assembly | High-volume stamping, blanking, coining |

| Cycle Speed | Slower, more deliberate | Faster, high-speed repetition |

| Versatility | High - adaptable ram speed, stroke, pressure | Low - fixed stroke and force profile |

Power Your Heavy-Duty Operations with KINTEK

Choosing the right press is critical to your productivity and product quality. Whether your application requires the sustained, controllable force of a hydraulic press or the high-speed efficiency of a mechanical press, KINTEK has the solution.

As a specialist in lab equipment and consumables, we provide robust presses built to meet the demanding needs of industrial and research laboratories. Our experts can help you select the perfect press to enhance your efficiency and ensure reliable performance for your most challenging tasks.

Contact KINTEK today for a personalized consultation and discover how our press solutions can drive your success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?