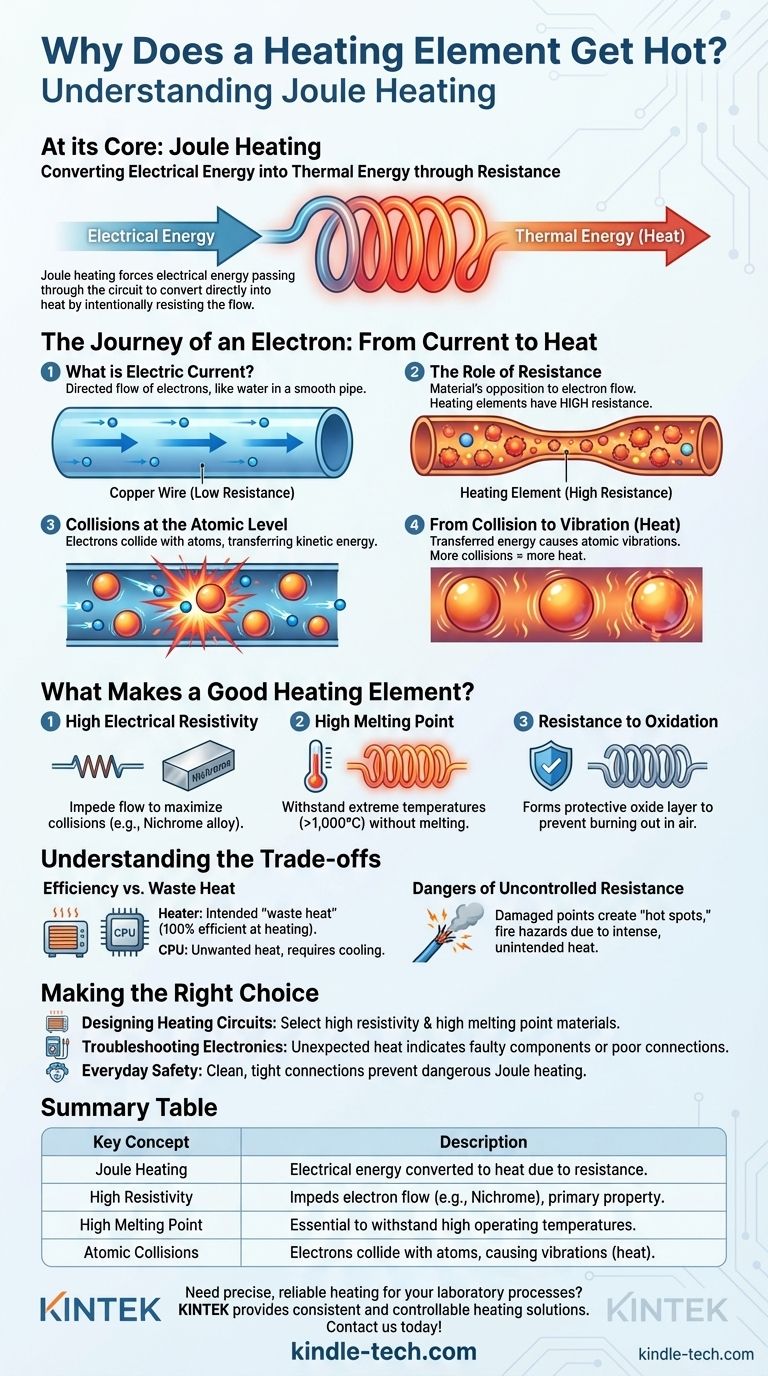

At its core, a heating element gets hot by intentionally resisting the flow of electricity. This process, known as Joule heating, forces the electrical energy passing through the circuit to convert directly into thermal energy, which we perceive and use as heat.

The key is not that heat is being created, but that electrical energy is being converted. A heating element is simply a material designed to make this conversion happen as efficiently as possible by acting as a form of controlled electrical friction.

The Journey of an Electron: From Current to Heat

To understand why a heating element works, you must first visualize what is happening at an atomic level when you turn on a device like a toaster or an electric heater.

What is Electric Current?

An electric current is simply the directed flow of charged particles, specifically electrons, through a material. Think of it as water flowing through a pipe.

The Role of Resistance

Resistance is a material's opposition to this flow of electrons. Materials with low resistance, like copper, are used for wires because they let electrons pass easily. A heating element, however, is made from a material with high resistance.

Using our analogy, a copper wire is a wide, smooth pipe. A heating element is a narrow, constricted pipe filled with obstacles.

Collisions at the Atomic Level

As electrons are forced through a high-resistance material (the heating element), they constantly collide with the atoms of that material. They don't have a clear path to flow through.

Each collision transfers kinetic energy from the moving electron to the atom it strikes. This is the fundamental interaction that generates heat.

From Collision to Vibration (Heat)

This transferred energy causes the atoms within the heating element's structure to vibrate vigorously. Heat, at its most basic level, is the collective vibration of atoms.

The more collisions that occur, the more the atoms vibrate, and the hotter the element becomes. This is the essence of Joule heating.

What Makes a Good Heating Element?

Not all materials are suitable for this task. Engineers select materials based on a few critical properties to ensure they produce heat effectively and reliably.

High Electrical Resistivity

The primary requirement is high electrical resistivity. You need a material that actively impedes the flow of electrons to maximize the number of energy-transferring collisions. Nichrome, an alloy of nickel and chromium, is a very common choice for this reason.

High Melting Point

A heating element must be able to get extremely hot without melting or degrading. Materials like Nichrome have very high melting points, allowing them to glow red-hot and operate safely at temperatures well over 1,000°C (1,832°F).

Resistance to Oxidation

When metals get hot, they tend to react with oxygen in the air, a process called oxidation (similar to rusting). A good heating element is stable and forms a protective outer layer of oxide that prevents it from quickly burning out.

Understanding the Trade-offs

While desirable in a heater, this effect is often a significant problem in other electronics.

Efficiency vs. Waste Heat

In a heating element, this "waste heat" is the intended product. The goal is to be 100% "inefficient" at transmitting electricity and 100% efficient at converting it to heat.

In a computer's CPU or a power line, however, Joule heating is a source of energy loss and a problem that must be managed. It's the reason CPUs require heat sinks and fans—to dissipate the unwanted heat generated by electrical resistance.

The Dangers of Uncontrolled Resistance

This principle also explains why a frayed wire or a poor electrical connection is a fire hazard. A damaged point in a circuit creates unintended, high-resistance "hot spots."

As current is forced through this small, resistive point, it generates intense, uncontrolled heat that can easily melt wire insulation and ignite nearby materials.

Making the Right Choice for Your Goal

Understanding this principle of energy conversion allows you to see your electrical world in a new light.

- If your primary focus is on designing a heating circuit: You must select a material with high resistivity and a high melting point, like Nichrome, sized for your specific voltage and desired power output.

- If your primary focus is on troubleshooting electronics: Remember that unexpected heat is almost always a sign of unwanted resistance, pointing you toward a faulty component or a poor connection.

- If your primary focus is on everyday safety: You can now recognize that maintaining clean, tight electrical connections is critical to preventing the dangerous effects of unintended Joule heating.

By controlling electrical resistance, we can either create the useful warmth of a heater or suffer the destructive consequences of an electrical fault.

Summary Table:

| Key Concept | Description |

|---|---|

| Joule Heating | The process where electrical energy is converted to heat due to resistance in a material. |

| High Resistivity | A primary property of good heating element materials (e.g., Nichrome) that impedes electron flow. |

| High Melting Point | Essential for the element to withstand high operating temperatures without degrading. |

| Atomic Collisions | Electrons colliding with atoms transfer energy, causing vibrations perceived as heat. |

Need precise, reliable heating for your laboratory processes?

At KINTEK, we understand that consistent and controllable heat is fundamental to your research and testing. Whether you require a standard laboratory furnace or a custom heating solution, our expertise in lab equipment ensures you get the performance and durability your work demands.

Contact us today to discuss how KINTEK's heating elements and laboratory furnaces can bring efficiency and reliability to your lab.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What is graphite heating? A Guide to Durable, High-Temp Industrial Furnace Solutions

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- How does the heating element work? Mastering Heat Transfer for Your Lab Equipment

- Can heating elements overheat? Prevent Burnout and Ensure Safe Operation

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- Why are K-type thermocouples shielded with niobium alloy tubes used? Ensure Accurate Microwave Pyrolysis Control

- What is the life expectancy of a heating element? Maximize Lifespan with Proper Care