In short, a muffle furnace is used for ash determination because it provides an extremely hot, controlled, and isolated environment. This design ensures that all organic material in a sample is completely burned away, leaving behind only the inorganic ash for accurate measurement without any risk of contamination from the heating source itself.

To accurately measure the ash content of a material, you must achieve two things: complete combustion of the organic components and zero contamination of the inorganic residue. A muffle furnace is the standard instrument for this task because its insulated chamber provides the uniform, high-heat environment necessary to guarantee both outcomes.

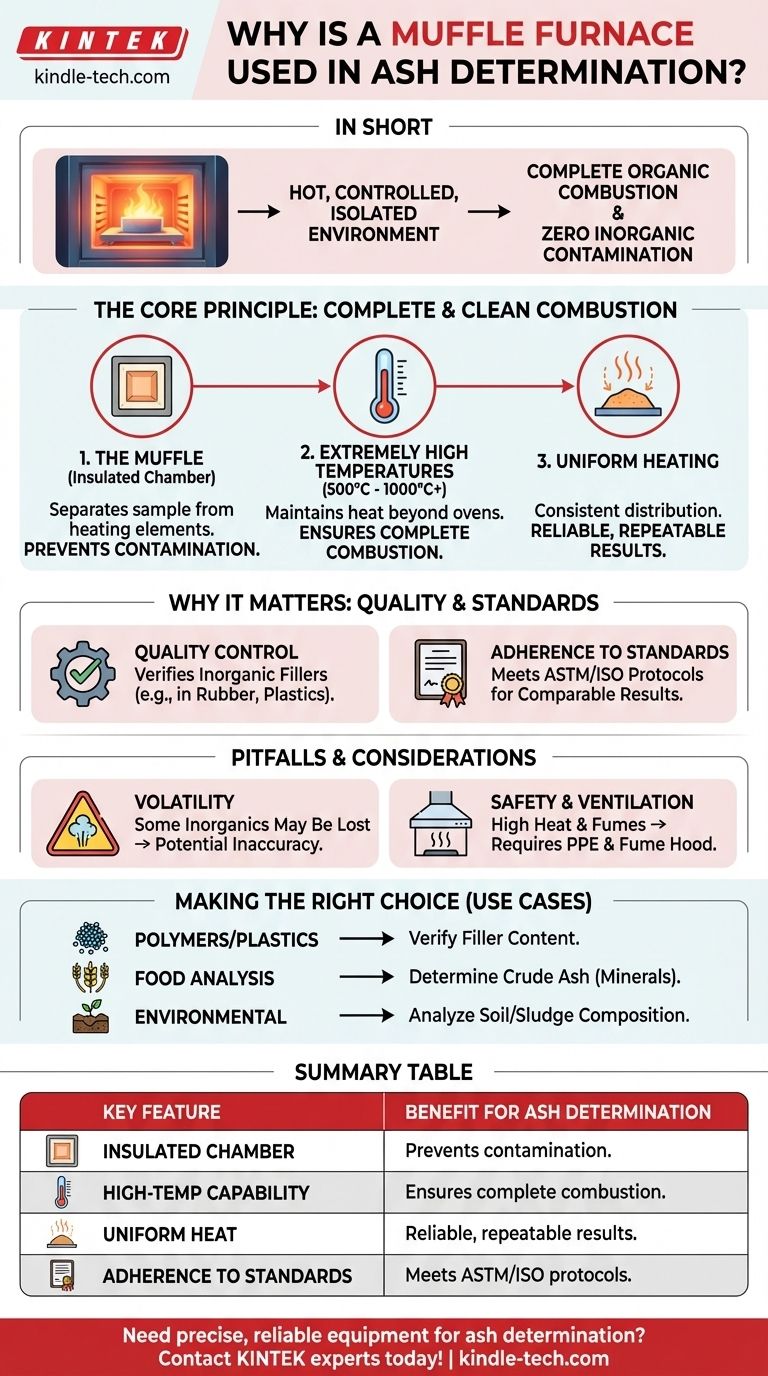

The Core Principle: Complete and Clean Combustion

The entire purpose of ash analysis is to precisely measure the weight of the non-combustible, inorganic material within a sample. A muffle furnace is purpose-built to facilitate this process through several key features.

The Importance of the "Muffle"

The defining feature of this furnace is the muffle—an insulated chamber, typically made of ceramic, that separates the test sample from the heating elements.

This separation is critical. It ensures the sample is heated by convection and radiation rather than direct contact with a flame or electric coil. This prevents contamination of the sample residue, which is essential for an accurate result.

Achieving Extremely High Temperatures

Ashing procedures often require sustained temperatures between 500°C and 1000°C, and sometimes higher.

Standard laboratory ovens cannot reach these temperatures. A muffle furnace is specifically designed to not only reach but also maintain these high temperatures for extended periods, ensuring complete combustion of even the most resilient organic compounds.

Ensuring Uniform Heating

The enclosed, insulated design of the muffle chamber provides exceptionally uniform heat distribution.

This guarantees that the entire sample is exposed to the same temperature conditions, eliminating hot or cold spots. Consistent heating leads to a more complete burn and, consequently, more reliable and repeatable results, which is vital for quality control.

Why This Matters in Material Analysis

Ash content is not just an academic measurement; it's a critical quality indicator in many industries. It often represents the quantity of inorganic fillers, minerals, or contaminants in a product.

A Standard for Quality Control

In materials like rubber, elastomers, and plastics, ash content directly relates to the amount of inorganic filler (like carbon black or silica) used.

Manufacturers use ash determination to verify that their products meet formulation specifications. An incorrect ash percentage can indicate an error in the manufacturing process, affecting the material's performance and properties.

Adherence to Standardized Methods

Industries rely on standardized testing protocols (such as those from ASTM or ISO) to ensure results are comparable across different facilities and companies.

These standards frequently mandate the use of a muffle furnace to create the specific, repeatable conditions required for an official analysis.

Common Pitfalls and Considerations

While highly effective, using a muffle furnace for ash determination is not without its limitations. Understanding these is key to accurate interpretation.

Volatility of Inorganic Compounds

The method assumes that only organic material is lost during heating. However, some inorganic compounds can be volatile at high temperatures and may be driven off along with the organic matter.

This can lead to an inaccurately low measurement of the true ash content. Analysts must be aware of the sample's composition to account for this possibility.

Safety and Ventilation

Operating at such high temperatures presents obvious safety risks. The combustion process can also release potentially hazardous fumes.

Proper personal protective equipment (PPE) and adequate ventilation, often a fume hood, are absolutely essential when performing this procedure.

Making the Right Choice for Your Goal

Using a muffle furnace is the correct approach when your analytical goal requires the separation and quantification of inorganic materials through high-temperature combustion.

- If your primary focus is quality control for polymers or plastics: A muffle furnace is the industry-standard tool for verifying the inorganic filler content against specifications.

- If your primary focus is analyzing nutritional content in food: This is the standard method for determining the total mineral content, often referred to as "crude ash."

- If your primary focus is environmental analysis of soil or sludge: Ashing helps determine the mineral versus organic matter ratio, a key indicator of composition and contamination.

Ultimately, the muffle furnace provides the precise, repeatable, and contamination-free heating environment that is indispensable for accurate ash determination.

Summary Table:

| Key Feature | Benefit for Ash Determination |

|---|---|

| Insulated Muffle Chamber | Prevents sample contamination from heating elements. |

| High-Temperature Capability | Ensures complete combustion of organic material. |

| Uniform Heat Distribution | Provides reliable and repeatable results. |

| Adherence to Standards | Meets ASTM/ISO protocols for quality control. |

Need precise, reliable equipment for your lab's ash determination or other analytical processes? KINTEK specializes in high-performance muffle furnaces and a full range of lab equipment and consumables. Our solutions are designed to deliver the accuracy and repeatability your quality control demands. Contact our experts today to find the perfect furnace for your application!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why must an MgO-coated substrate undergo annealing before electrolyte deposition? Enhance Layer Stability and Performance

- Why is it important to determine ash in processed foods? Ensure Quality, Nutrition & Compliance

- Why is a high-precision Muffle Furnace essential for AFA steel? Optimize Your Solution Treatment Results

- Why is a high-temperature muffle furnace used during MCM-41 synthesis? Unlock Maximum Porosity and Surface Area

- What is an ashing furnace? A Key Tool for Precise Material Analysis Across Industries

- Why is heat treatment in a high-temperature furnace required for stainless steel corrosion testing? Ensure Data Reliability

- Why is a muffle furnace heated to 550 °C for PCN synthesis? Master Thermal Polymerization for Quality Carbon Nitride

- How is a sintering furnace used to study CuMH? Precision Thermal Control for Advanced Ionic Transport Research