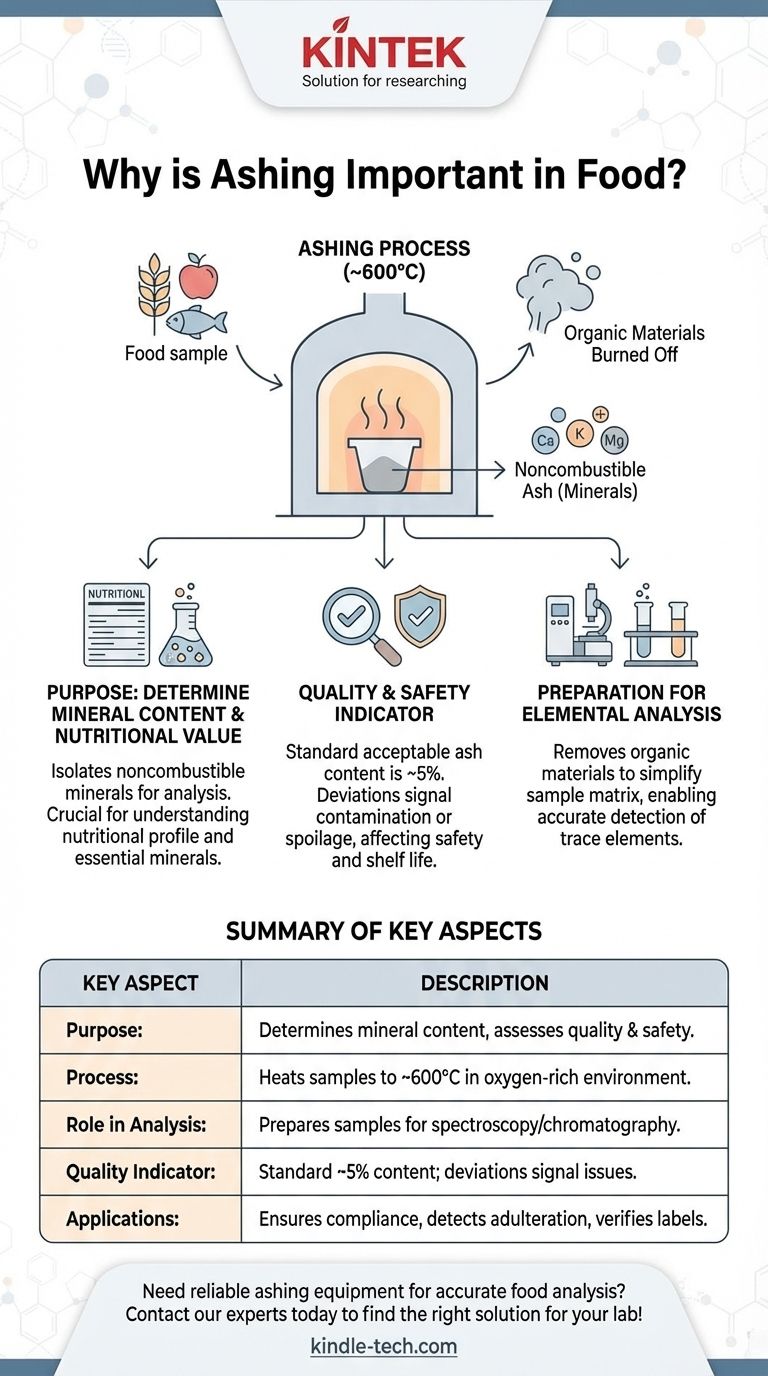

Ashing is a critical process in food science and analytical chemistry, primarily used to determine the mineral composition of food samples. By heating the sample to high temperatures (around 600°C) in an oxygen-rich environment, organic materials are burned off, leaving behind noncombustible ash composed of minerals like oxides and sulfates. This ash content is then analyzed to estimate mineral concentrations, which is essential for assessing food quality, safety, and nutritional value. Ashing also serves as a preparatory step for further elemental analysis, such as spectroscopy or chromatography, ensuring accurate results by removing unwanted organic materials. Maintaining an appropriate ash content (typically around 5%) is vital for food quality control, as deviations can indicate issues like contamination or aging.

Key Points Explained:

-

Purpose of Ashing in Food Analysis:

- Ashing is primarily used to determine the mineral content in food samples. By burning off organic materials, the process isolates noncombustible minerals, which are then analyzed to estimate their concentration.

- This is crucial for understanding the nutritional profile of food, as minerals like calcium, potassium, and magnesium are essential for human health.

-

Process of Dry Ashing:

- The sample is heated in an ashing furnace to temperatures around 600°C (1112°F) in the presence of oxygen.

- Organic components are oxidized and volatilized, leaving behind inorganic minerals in the form of oxides, sulfates, and other compounds.

- The remaining ash is weighed to determine the mineral content based on dry-weight ash content.

-

Role in Elemental Analysis:

- Ashing serves as a preliminary step for further elemental analysis techniques, such as spectroscopy or chromatography.

- By removing organic materials, ashing simplifies the sample matrix, making it easier to detect and quantify trace elements.

-

Importance in Food Quality and Safety:

- Ash content is a key indicator of food quality. A standard acceptable ash content is around 5%, and deviations from this can signal issues like contamination or spoilage.

- Higher ash content may indicate the presence of inorganic contaminants or the aging of the food product, which can affect safety and shelf life.

-

Applications in the Food Industry:

- Ashing is widely used in the food industry to ensure compliance with regulatory standards and to maintain product consistency.

- It helps in assessing the purity of ingredients, detecting adulteration, and verifying nutritional claims on food labels.

-

Connection to Analytical Chemistry:

- Ashing is a form of mineralization, which preconcentrates trace substances for more accurate chemical analysis.

- This process is essential for techniques like optical analysis (e.g., spectroscopy) and separation methods (e.g., chromatography), where the presence of organic materials could interfere with results.

-

Practical Implications for Food Purchasers:

- For equipment and consumable purchasers, understanding the importance of ashing can guide the selection of appropriate ashing furnaces and related analytical tools.

- Ensuring that the equipment can achieve and maintain the required temperatures and oxygen flow is critical for accurate ash content determination.

By understanding the role of ashing in food analysis, stakeholders can better appreciate its significance in ensuring food quality, safety, and compliance with industry standards. This knowledge also aids in making informed decisions about the equipment and consumables needed for accurate and reliable mineral analysis.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Determines mineral content and assesses food quality, safety, and nutritional value. |

| Process | Heats samples to ~600°C in oxygen-rich environments to burn off organic materials. |

| Role in Analysis | Prepares samples for spectroscopy or chromatography by removing organic materials. |

| Quality Indicator | Standard ash content (~5%) signals food quality; deviations indicate contamination. |

| Applications | Ensures compliance, detects adulteration, and verifies nutritional claims. |

| Equipment Considerations | Requires precise temperature control and oxygen flow for accurate results. |

Need reliable ashing equipment for accurate food analysis? Contact our experts today to find the right solution for your lab!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- What are the four steps to the heat treating process? Master the 3 Core Stages for Superior Results

- What are the applications of muffle furnaces? Essential Tools for High-Temperature Processes

- What are the roles of laboratory drying ovens and muffle furnaces in biomass analysis? Precision Thermal Treatment

- What is the burning temperature of a furnace? From 200°C to 3000°C, It Depends on Your Needs