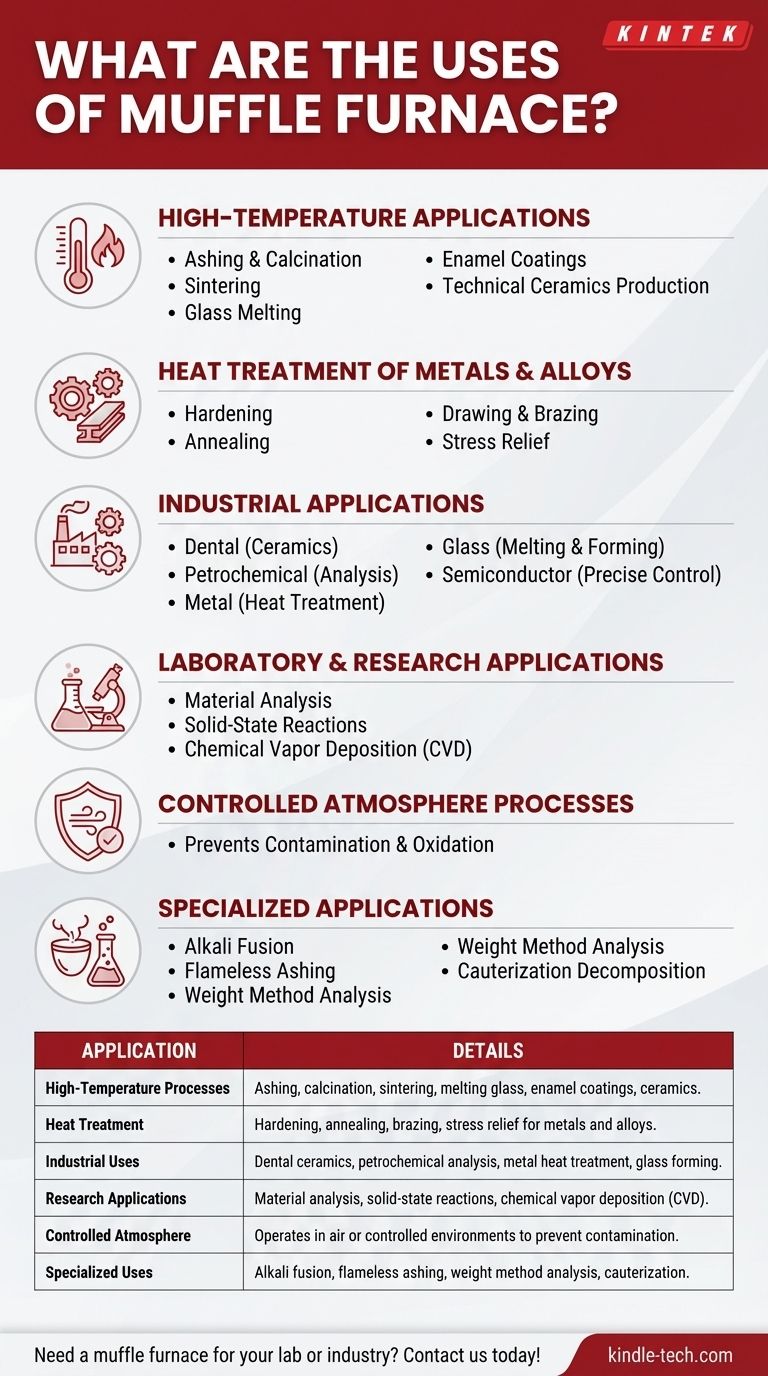

Muffle furnaces are versatile and essential tools in both industrial and laboratory settings, designed for high-temperature applications that require precise and contamination-free heating. They are used for processes such as ashing, calcination, sintering, heat treatment, and creating enamel coatings, among others. These furnaces are widely employed in industries like dental, petrochemical, metal, glass, and semiconductor manufacturing, as well as in research facilities for material analysis and synthesis. Their ability to operate in controlled atmospheres and reach temperatures up to 1200°C or higher makes them indispensable for tasks like melting glass, annealing metals, and producing technical ceramics.

Key Points Explained:

-

High-Temperature Applications:

- Muffle furnaces are capable of reaching temperatures up to 1200°C or higher, making them suitable for processes like ashing, calcination, and sintering.

- These high temperatures are essential for processes such as melting glass, creating enamel coatings, and producing technical ceramics.

-

Heat Treatment of Metals and Alloys:

- Muffle furnaces are used for various heat treatment processes including hardening, annealing, drawing, brazing, and stress relief.

- These processes improve the mechanical properties of metals and alloys, making them more suitable for specific applications.

-

Industrial Applications:

- Dental Industry: Used for creating dental ceramics and other materials.

- Petrochemical Industry: Employed in the analysis and treatment of materials.

- Metal Industry: Essential for heat treating metals and alloys.

- Glass Industry: Used for melting and forming glass.

- Semiconductor Industry: Crucial for processes requiring precise temperature control.

-

Laboratory and Research Applications:

- Material Analysis: Used for determining the non-combustible and non-volatile percentage of samples.

- Solid-State Reactions: Essential for reducing metals, creating oxides, and other high-temperature chemical reactions.

- Chemical Vapor Deposition (CVD): Used in high-temperature CVD processes for material synthesis.

-

Controlled Atmosphere Processes:

- Muffle furnaces can operate in both air and controlled atmospheres, which is crucial for processes that require specific environmental conditions to prevent contamination or oxidation.

-

Specialized Applications:

- Alkali Fusion: Used for the fusion of refractory metals and minerals.

- Weight Method of Analysis: Employed in analytical chemistry for precise measurements.

- Flameless Ashing: Used for the ashing of filter paper and other materials without the risk of contamination.

- Cauterization Decomposition: Essential for the decomposition of organic materials and the expulsion of volatile components from inorganic matter.

-

Precision and Uniform Heating:

- Muffle furnaces provide precise temperature control and uniform heating, which are critical for consistent and reliable results in both industrial and laboratory settings.

-

Versatility:

- The wide range of applications, from ashing and calcination to sintering and heat treatment, highlights the versatility of muffle furnaces in various fields.

In summary, muffle furnaces are indispensable tools in both industrial and laboratory environments due to their ability to provide high-temperature, precise, and contamination-free heating. Their applications span across various industries and research fields, making them a critical component in material processing and analysis.

Summary Table:

| Application | Details |

|---|---|

| High-Temperature Processes | Ashing, calcination, sintering, melting glass, enamel coatings, ceramics. |

| Heat Treatment | Hardening, annealing, brazing, stress relief for metals and alloys. |

| Industrial Uses | Dental ceramics, petrochemical analysis, metal heat treatment, glass forming. |

| Research Applications | Material analysis, solid-state reactions, chemical vapor deposition (CVD). |

| Controlled Atmosphere | Operates in air or controlled environments to prevent contamination. |

| Specialized Uses | Alkali fusion, flameless ashing, weight method analysis, cauterization. |

Need a muffle furnace for your lab or industry? Contact us today to find the perfect solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab