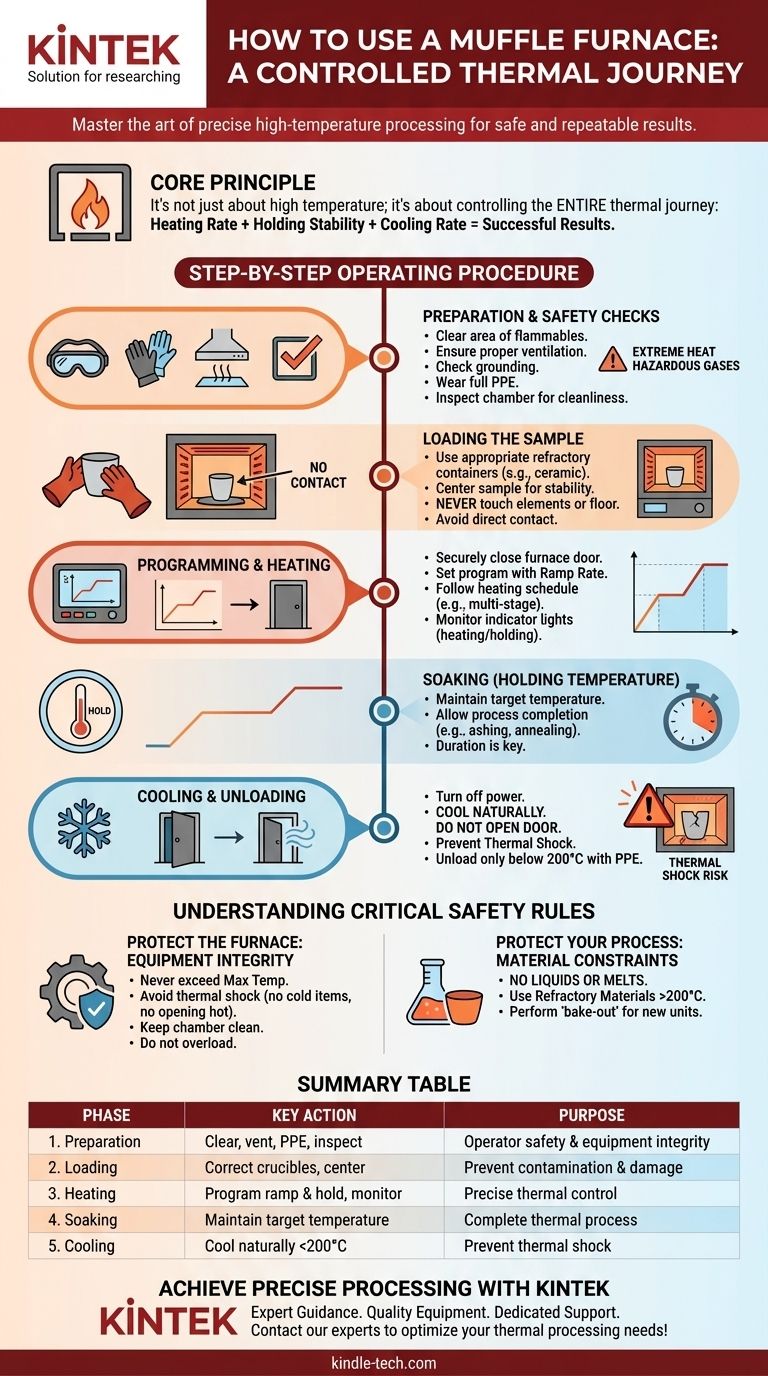

To use a muffle furnace, you must follow a precise procedure that begins with safety checks and sample preparation, moves to programming a controlled heating cycle, and ends with a gradual, safe cooling phase before removing your materials. This methodical approach ensures the safety of the operator, the integrity of the furnace, and the accuracy of your results.

The core principle of using a muffle furnace is not simply reaching a high temperature, but controlling the entire thermal journey. Safe operation and repeatable results depend on managing the rate of heating, the stability of the holding temperature, and, most critically, the rate of cooling.

The Purpose of a Muffle Furnace: More Than Just a Hot Box

A muffle furnace is a specialized oven that provides an environment for high-temperature applications. Its defining feature is the "muffle," an insulating chamber that separates the material being heated from the heating elements and any potential contaminants from combustion.

Uniform, Controlled Heating

The primary advantage is precise temperature control and exceptionally uniform heat distribution. This is critical for processes where exact thermal conditions dictate the outcome, such as annealing metals or synthesizing advanced materials.

A Contaminant-Free Environment

By isolating the sample, the furnace prevents byproducts of combustion or direct radiation from the heating elements from affecting the material. This is essential for applications like quantitative analysis (ashing), where any foreign material would skew the results.

Step-by-Step Operating Procedure

Proper use involves distinct phases, each with its own set of critical actions. Following this sequence minimizes risk and ensures a successful run.

Phase 1: Preparation and Safety Checks

Before turning the furnace on, prepare your workspace and the equipment itself.

- Clear the Area: Ensure no combustible or flammable materials are near the furnace. The exterior surfaces become extremely hot.

- Ensure Ventilation: The furnace should be in a well-ventilated area or under a fume hood, especially if your process releases gases.

- Check Grounding: Verify that the furnace and its controller are properly grounded to prevent electrical hazards.

- Wear PPE: Always wear appropriate personal protective equipment, including heat-resistant gloves and safety glasses.

- Inspect the Chamber: Look inside the furnace. It should be clean and free of any residue or forgotten items from a previous run.

Phase 2: Loading the Sample

How you place your sample into the furnace is critical for both safety and success.

- Use Correct Materials: Only place samples in appropriate refractory containers, such as ceramic or high-purity alumina crucibles.

- Ensure Stability: Place the crucible securely in the center of the furnace chamber. It must be stable and not at risk of tipping over.

- Avoid Direct Contact: Never place samples directly on the furnace floor or in contact with the heating elements. This creates a fire risk and can destroy the elements.

Phase 3: Programming and Heating

This is the active heating phase. Control is paramount.

- Close the Door: Securely shut the furnace door to prevent heat loss and maintain a stable atmosphere.

- Set the Program: Turn on the power and set your temperature controller. Instead of just setting a final temperature, you often need to program a ramp rate (how fast it heats up).

- Follow a Heating Schedule: Many processes require a multi-stage approach. For example, slowly heating to 200°C and holding for a period to drive off moisture before ramping to a final, higher temperature.

- Monitor the System: Modern controllers often have indicator lights (e.g., green for heating, red for holding at the set temperature). Keep an eye on the process to ensure it is proceeding as expected.

Phase 4: Soaking (Holding Temperature)

Once the furnace reaches the target temperature, it enters the "soaking" or "holding" phase. The controller will maintain this temperature for the programmed duration, allowing the desired thermal process (e.g., ashing, annealing, sintering) to complete.

Phase 5: Cooling and Unloading

The cooling phase is as important as the heating phase and is a common point of failure.

- Turn Off Power: Once the holding time is complete, turn the furnace off.

- Do Not Open the Door: Resist the urge to open the door to speed up cooling. The resulting thermal shock can crack the furnace's refractory lining or shatter your sample.

- Cool Naturally: Let the furnace cool down slowly over several hours, ideally overnight.

- Unload at a Safe Temperature: Only when the furnace has cooled to a safe temperature (typically below 150-200°C) should you use heat-resistant gloves to open the door and remove your sample.

Understanding Critical Safety Rules

A muffle furnace is a powerful tool that commands respect. Ignoring safety protocols can lead to equipment damage, ruined experiments, and serious injury.

Protect the Furnace: Equipment Integrity

- Never Exceed Max Temperature: Do not operate the furnace above its rated temperature, as this will burn out the heating elements.

- Avoid Thermal Shock: Do not place cold items in a hot furnace or open the door while at high temperature.

- Keep it Clean: Regularly clean the chamber to prevent cross-contamination and damage from residue.

- No Overloading: Do not overload the furnace, as this can lead to uneven heating and potential hazards.

Protect Your Process: Material Constraints

- No Liquids or Melts: It is forbidden to pour liquids or easily melted metals directly into the furnace. A spill can destroy the insulation and heating elements.

- Use Refractory Materials: For any process above 200°C, all materials placed inside the furnace must be refractory and able to withstand the target temperature.

A Note on First Use

If the furnace is new or has been unused for a long time, it is wise to perform an empty "bake-out" run. Heat it slowly to a moderate temperature (e.g., 200-300°C) and hold it for a few hours to burn off any absorbed moisture or manufacturing residues.

Applying This to Your Goal

Your specific heating profile will depend on your objective.

- If your primary focus is ashing or burn-off: Use a slow initial ramp rate to prevent the sample from violently combusting and ensure adequate ventilation to remove fumes.

- If your primary focus is heat-treating metals or ceramics: The precision of your heating program, including ramp rates, hold times, and especially the controlled cooling rate, is what determines the final properties of your material.

- If your primary focus is general lab safety: Always treat the furnace as a high-energy system where the cooldown process is just as critical as the heating process.

Mastering the muffle furnace is about understanding and controlling the entire thermal cycle to achieve safe, reliable, and repeatable results.

Summary Table:

| Phase | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Clear area, check ventilation, wear PPE, inspect chamber. | Ensure operator safety and equipment integrity. |

| 2. Loading | Use correct crucibles, center sample, avoid contact with elements. | Prevent contamination and damage, ensure uniform heating. |

| 3. Heating | Program ramp rate and hold times, close door securely, monitor. | Achieve precise thermal control for the process. |

| 4. Soaking | Maintain target temperature for the programmed duration. | Complete the thermal process (e.g., ashing, annealing). |

| 5. Cooling | Turn off power, let cool naturally, do not open door until <200°C. | Prevent thermal shock to the furnace and sample. |

Achieve Precise and Safe High-Temperature Processing with KINTEK

Mastering thermal cycles is essential for reliable ashing, annealing, and material synthesis. KINTEK specializes in high-quality laboratory furnaces and consumables designed for safety, precision, and durability.

Let us help you enhance your lab's capabilities:

- Expert Guidance: Get support in selecting the right furnace for your specific application.

- Quality Equipment: Ensure repeatable results with our reliable muffle furnaces and refractory crucibles.

- Dedicated Support: We serve laboratories by providing the equipment and knowledge needed for successful high-temperature processes.

Ready to optimize your thermal processing? Contact our experts today to discuss your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the specific function of a box resistance furnace in Li2MnO3 synthesis? Master Precursor Powder Preparation

- How do high-temperature electric furnaces facilitate HLW immobilization? Master the Two-Stage Crystallization Process

- What function does a high-temperature muffle furnace perform during the synthesis of La0.6Sr0.4CoO3-δ perovskite oxides?

- What is the muffle furnace method? A Guide to Clean, High-Temperature Processing

- What is the function of a laboratory oven in the pretreatment of cigarette filter waste? Preserving Cellulose Acetate

- What role does an electric muffle furnace play during the solution treatment? Achieve Material Homogenization

- What is the purpose of high-temperature muffle furnaces and ceramic crucibles? Master NREL Ash Analysis

- Why is a high-temperature muffle furnace utilized for the calcination of Ni-Ag catalyst precursors? Optimize Activity