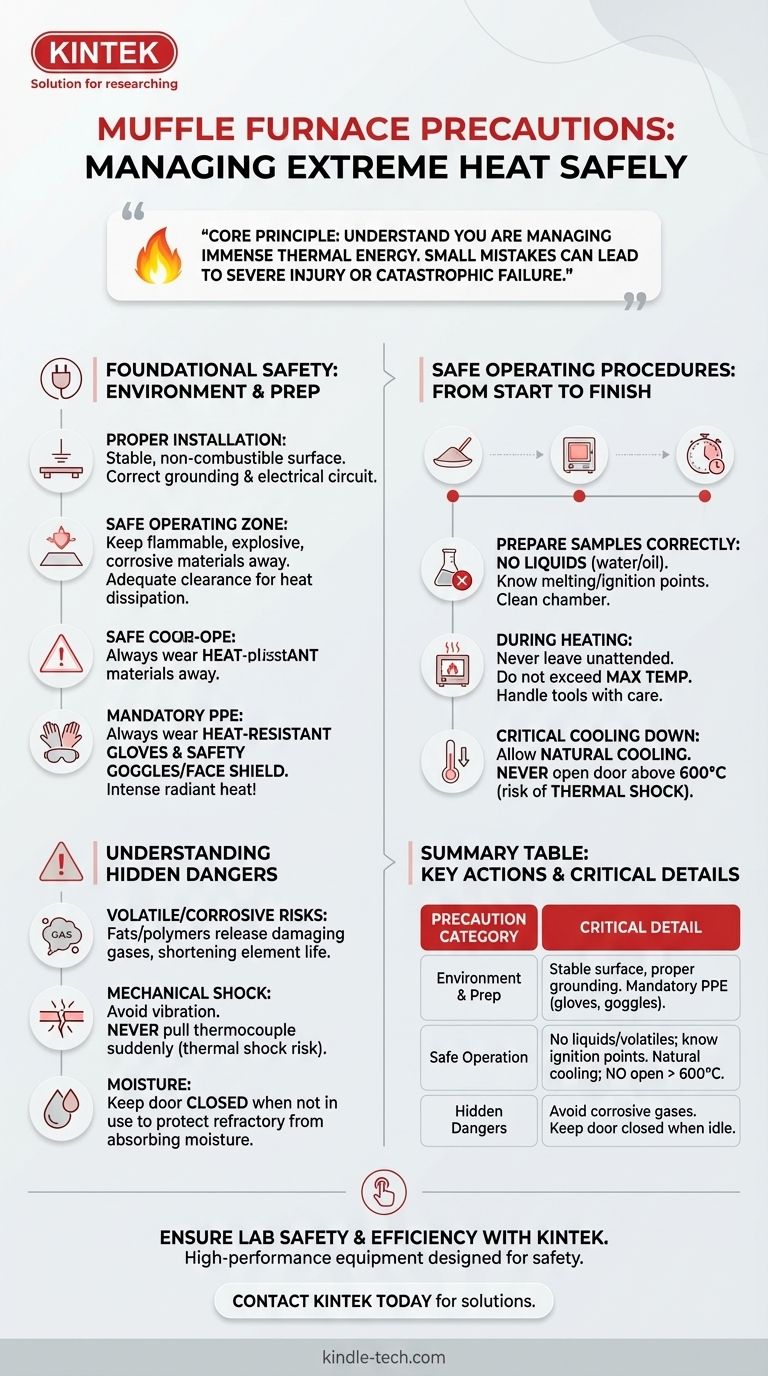

The most critical precautions for using a muffle furnace involve a systematic approach to managing extreme heat, ensuring sample stability, and maintaining a safe operating environment. You must always use appropriate personal protective equipment (PPE), never introduce liquids or volatile substances into the chamber, and allow the furnace to cool naturally before opening the door.

A muffle furnace is a powerful tool that demands respect. The core principle of its safe operation is not merely following a checklist, but understanding that you are managing immense thermal energy, where even small mistakes can lead to severe injury or catastrophic equipment failure.

Foundational Safety: Environment and Preparation

Before you even turn the furnace on, the stage must be set for a safe operation. Neglecting these foundational steps introduces unacceptable risk.

Proper Installation and Electrical Safety

A muffle furnace draws significant power and generates intense external heat. Proper installation is your first line of defense.

It must be placed on a stable, level, and non-combustible surface, such as a dedicated cement platform.

Ensure the furnace is connected to an appropriate circuit with the correct plugs, sockets, and fuses. Crucially, the unit must be properly grounded to prevent electrical shock.

Creating a Safe Operating Zone

The area around the furnace is just as important as the furnace itself. Keep the immediate environment clear of all flammable, explosive, or corrosive materials.

The furnace jacket will become extremely hot. Maintain adequate clearance from walls and other equipment to allow for heat dissipation and prevent accidental contact.

Personal Protective Equipment (PPE) is Non-Negotiable

The intense radiant heat from a muffle furnace can cause severe burns in an instant.

Always wear heat-resistant gloves and safety goggles or a face shield when loading, unloading, or operating the furnace. The type of glove must be rated for the temperatures you are working with.

Safe Operating Procedures: From Start to Finish

A safe workflow involves careful preparation of what goes into the furnace, vigilant monitoring during the cycle, and a patient cooling-down process.

Preparing Your Samples Correctly

The most common failures originate from improperly prepared samples. The furnace chamber must be kept immaculately clean.

It is strictly forbidden to heat liquid samples like water or oil, as rapid vaporization can damage the heating elements or the chamber itself. Never pour liquids or molten metals directly into the furnace.

You must know the melting or ignition point of all materials placed inside. Ensure everything can withstand the programmed temperature to avoid unexpected chemical reactions or damage.

For glassware, cover the open ends of Pyrex with aluminum foil to contain any potential spattering.

During the Heating Cycle

Once the cycle begins, the furnace requires active monitoring. Never leave a high-temperature operation unattended, especially overnight, in case of control failure.

Do not exceed the maximum rated temperature of the furnace. Operating at the highest temperature for prolonged periods can significantly shorten the life of the heating elements.

Handle tools like crucible tongs with care and close the furnace door gently to avoid damaging the refractory lining or the door seal.

The Critical Cooling Down Phase

The cooling phase is as critical as the heating phase. A sudden change in temperature can crack the furnace chamber or shatter your sample.

After the cycle is complete, turn off the power and allow the furnace to cool down naturally.

Never open the door when the temperature is above 600°C. Opening the door at high temperatures can cause severe thermal shock to the furnace and expose the operator to a blast of extreme heat.

Understanding the Hidden Dangers

Beyond the obvious risk of heat, several less-apparent dangers can compromise safety and damage the equipment.

The Risk of Volatile or Corrosive Materials

Heating materials that contain substances like fats or certain polymers can release volatile and corrosive gases.

These gases can attack the surface of the heating elements, leading to premature failure and a shortened furnace lifespan.

The Danger of Mechanical Shock

Avoid operating the furnace if it is vibrating. More importantly, never pull the thermocouple out suddenly when the furnace is at a high temperature, as this can cause the protective jacket to burst from thermal shock.

Moisture: The Silent Enemy

When not in use, the furnace door should be kept closed. This protects the delicate refractory material from absorbing ambient moisture.

If a furnace has been idle for a long time, it may need a low-temperature drying cycle performed before being used for a high-temperature application.

Making the Right Choice for a Safe Protocol

Your safety protocol should be tailored to your specific role and responsibilities within the lab.

- If your primary focus is daily operation: Prioritize the routine of wearing correct PPE, meticulously preparing samples, and never leaving the furnace unattended during a run.

- If your primary focus is lab management: Ensure all users are properly trained, the furnace's physical location is secure and clear, and a regular maintenance schedule is in place.

- If your primary focus is emergency preparedness: Ensure a suitable fire extinguisher is accessible, all users know the emergency power-off procedure, and first-aid for burns is readily available.

Ultimately, consistent adherence to these safety protocols is the defining line between a reliable scientific instrument and a significant hazard.

Summary Table:

| Precaution Category | Key Action | Critical Detail |

|---|---|---|

| Environment & Prep | Proper Installation | Stable, non-combustible surface; correct electrical grounding. |

| Personal Protective Equipment (PPE) | Heat-resistant gloves and safety goggles are mandatory. | |

| Safe Operation | Sample Preparation | Never introduce liquids or volatile substances; know material ignition points. |

| Cooling Down | Allow natural cooling; never open door above 600°C to avoid thermal shock. | |

| Hidden Dangers | Material Risks | Avoid corrosive gases that can damage heating elements. |

| Maintenance | Keep door closed when not in use to protect refractory from moisture. |

Ensure your lab's safety and efficiency with the right equipment. Proper handling is critical, but it starts with a reliable muffle furnace. KINTEK specializes in high-performance lab equipment and consumables, designed with safety and durability in mind. Our experts can help you select the perfect furnace for your specific application and provide guidance on best practices.

Don't compromise on safety. Contact KINTEK today to discuss your laboratory needs and discover how our solutions can protect your team and enhance your results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the importance of determining the ash and mineral content? Ensure Material Quality and Purity

- What role does a high-temperature muffle furnace play in the synthesis of TiO2/POFA hybrid photocatalysts?

- How do you test for ash? Choose the Right Method for Accurate Mineral Analysis

- What is another name for a muffle furnace? Understanding the Core Principle of Isolated Heating

- What does 'sintered' mean? Unlock the Power of Solid-State Manufacturing

- How do high-temperature furnaces and quenching media evaluate Cr/CrxN coatings? Testing Thermal Shock Durability

- What role does a high-temperature muffle furnace play in BZCY72 densification? Master Precision Sintering at 1500°C

- How do high-temperature furnaces facilitate the pre-treatment of minerals? Optimize Solid-Solid Reactions