At its core, Chemical Vapor Deposition (CVD) is important because it is a foundational process for building the modern world at a microscopic level. It is one of the few manufacturing techniques that allows for the creation of exceptionally pure, uniform, and ultra-thin solid films over complex surfaces, making it indispensable for high-performance electronics, advanced materials like graphene, and durable protective coatings.

The true importance of CVD lies not in any single advantage, but in its unique combination of atomic-level precision, material purity, and surface versatility. This allows engineers and scientists to construct materials and devices from the atoms up, a capability that underpins much of modern technology.

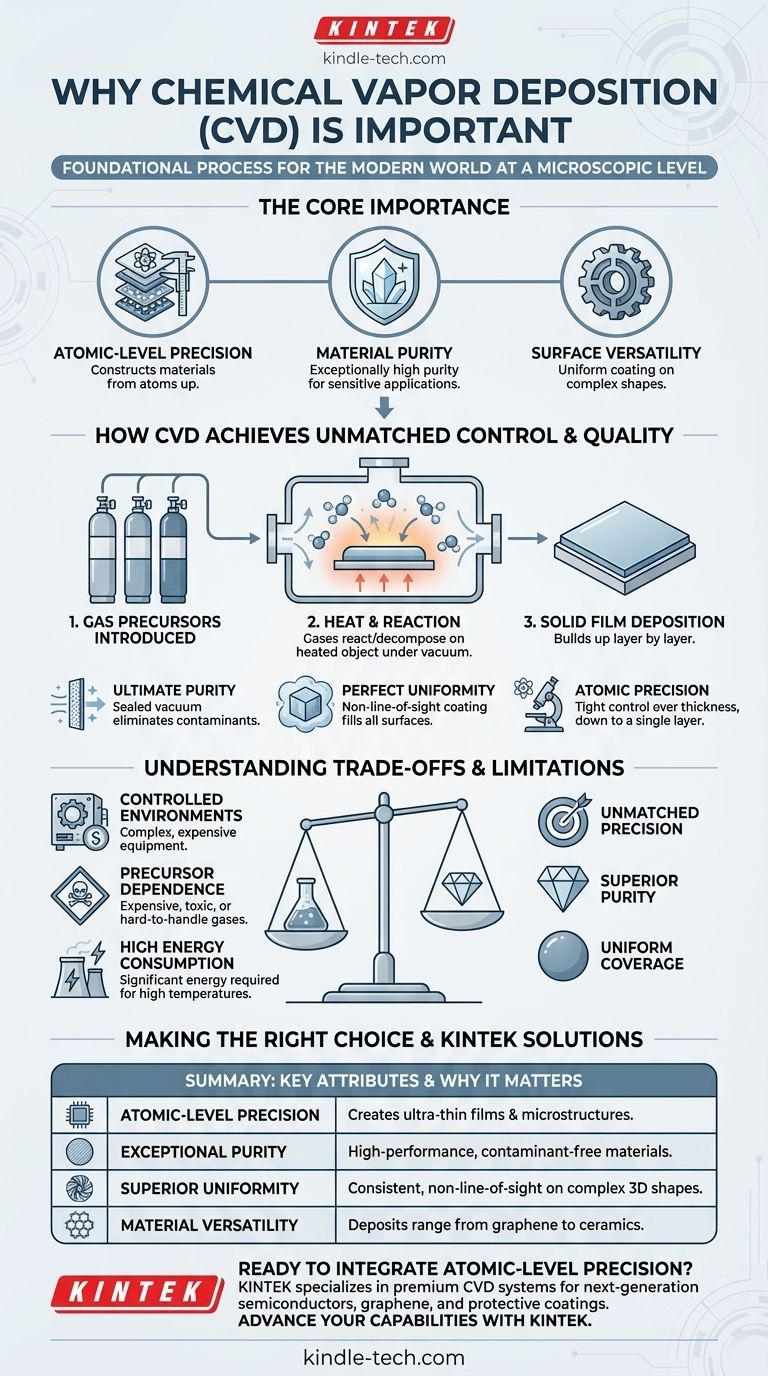

How CVD Achieves Unmatched Control and Quality

To understand why CVD is so critical, you must first understand its fundamental mechanism. The process grants a level of control that few other manufacturing techniques can match.

The Core Mechanism: From Gas to Solid Film

CVD involves introducing one or more volatile precursor gases into a reaction chamber under vacuum.

When the chamber is heated, these gases react or decompose on the surface of a heated object (the substrate).

This chemical reaction results in the deposition of a thin, solid film of the desired material onto the substrate, building it up layer by layer.

Achieving Ultimate Purity

The entire process occurs within a sealed, vacuumed environment.

By precisely controlling the precursor gases and eliminating unwanted atmospheric contaminants, CVD can produce films of exceptionally high purity. This is non-negotiable for applications like semiconductors, where even tiny impurities can ruin a device.

Ensuring Perfect Uniformity

Because the precursor materials are in a gas phase, they flow to fill the entire chamber.

This non-line-of-sight nature means the gas can reach and coat all exposed surfaces of an object evenly, regardless of its shape or complexity. This is a significant advantage over methods that can only coat what is directly in front of them.

Precision Down to the Atomic Layer

The deposition rate is governed by factors like temperature, pressure, and gas flow, all of which can be tightly controlled.

This gives manufacturers the ability to create ultra-thin films with precision down to a single layer of atoms. This level of control is essential for fabricating the microscopic structures found in modern electrical circuits and microchips.

Understanding the Trade-offs

While powerful, CVD is not a universal solution. Its precision comes with specific operational requirements that create practical limitations.

Requirement for Controlled Environments

The need for a vacuum chamber and high temperatures means that CVD equipment is often complex and expensive.

This initial capital investment can make it less suitable for applications that do not require its high level of precision or purity.

Dependence on Precursor Materials

The process relies on volatile precursor gases, which can be expensive, toxic, or difficult to handle safely.

The choice of what material you can deposit is limited by the availability of a suitable chemical precursor that will behave correctly under CVD conditions.

High Energy Consumption

Reaching and maintaining the high reaction temperatures required for the chemical reactions consumes a significant amount of energy.

This can contribute to higher operational costs and has an environmental impact that must be considered.

Making the Right Choice for Your Goal

Selecting a deposition technique depends entirely on the requirements of your final product. CVD excels where purity, uniformity, and thin-film control are the highest priorities.

- If your primary focus is ultimate material purity and atomic-level control: CVD is the definitive choice for applications like manufacturing semiconductors, high-performance sensors, and next-generation materials like graphene.

- If your primary focus is coating complex 3D shapes with a perfectly uniform layer: CVD's non-line-of-sight nature makes it a superior solution where methods like sputtering or evaporation would fail to provide even coverage.

- If your primary focus is a simple, low-cost protective coating on a flat surface: You should evaluate potentially more cost-effective processes, as the high precision of CVD may be unnecessary for your goal.

Ultimately, understanding the principles of CVD allows you to select the precise manufacturing tool needed to turn an innovative concept into a physical reality.

Summary Table:

| Key Attribute | Why It Matters |

|---|---|

| Atomic-Level Precision | Enables creation of ultra-thin films and complex microstructures. |

| Exceptional Purity | Produces high-performance materials free from contaminants. |

| Superior Uniformity | Provides consistent, non-line-of-sight coating on complex 3D shapes. |

| Material Versatility | Deposits a wide range of high-performance materials, from graphene to ceramics. |

Ready to Integrate Atomic-Level Precision into Your Lab?

If your research or production demands exceptionally pure, uniform thin films, the controlled environment of a CVD system is essential. KINTEK specializes in premium lab equipment, including Chemical Vapor Deposition systems, to help you fabricate next-generation semiconductors, advanced materials like graphene, and durable protective coatings.

Contact our experts today to discuss how a CVD solution from KINTEK can advance your materials science and manufacturing capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is a cathode sputtering? A Guide to Precision Thin-Film Deposition

- What are the advantages and primary use of HFCVD systems? Master Diamond Film Production with Ease

- What are the three methods of deposition of carbon nanotubes? Arc Discharge, Laser Ablation, and CVD

- What is the growth mechanism of chemical vapour deposition? Master the 5 Stages of Atomic-Level Film Growth

- What is sputtering in physics? A Guide to Atomic-Level Thin Film Deposition

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is an example of a chemical vapor deposition? Discover How CVD Builds Microchips and Solar Panels