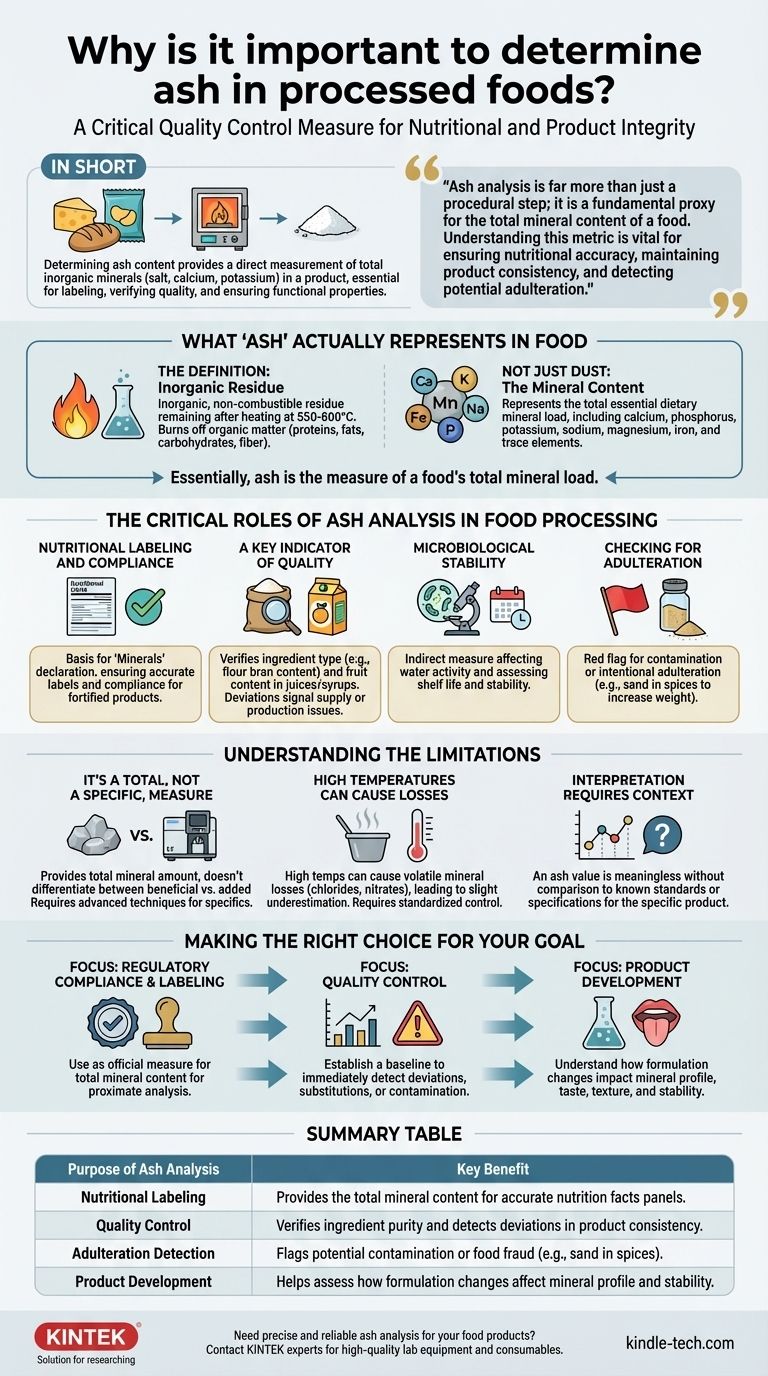

In short, determining the ash content of processed food is a critical quality control measure. It provides a direct measurement of the total amount of inorganic minerals—such as salt, calcium, and potassium—present in a food product. This single value is essential for nutritional labeling, verifying ingredient quality, and ensuring the final product meets its specified functional properties.

Ash analysis is far more than just a procedural step; it is a fundamental proxy for the total mineral content of a food. Understanding this metric is vital for ensuring nutritional accuracy, maintaining product consistency, and detecting potential adulteration.

What 'Ash' Actually Represents in Food

The Definition: Inorganic Residue

The term "ash" refers to the inorganic, non-combustible residue that remains after a food sample is heated at very high temperatures (typically 550-600°C).

This process, known as incineration or ashing, effectively burns off all the organic matter—namely proteins, fats, carbohydrates, and fiber.

Not Just Dust: The Mineral Content

What is left behind is the food's total mineral content. These are the essential dietary minerals we need for health, such as calcium, phosphorus, potassium, sodium, magnesium, and iron, as well as trace elements.

Essentially, ash is the measure of a food's total mineral load.

The Critical Roles of Ash Analysis in Food Processing

Nutritional Labeling and Compliance

Ash analysis is a cornerstone of proximate analysis, the system used to determine the macronutrient and mineral profile of a food. The total ash value is often the basis for the "Minerals" declaration on a nutrition facts panel.

Regulators rely on this data to ensure that food labels are accurate and that fortified products contain the declared amount of added minerals.

A Key Indicator of Quality

The ash content is a powerful indicator of the quality and type of ingredients used. For example, in flour milling, a higher ash content indicates a larger proportion of bran in the flour, which affects its baking properties and final texture.

For fruit juices and syrups, ash content can help verify the fruit content and detect if it has been diluted or adulterated. A deviation from the expected ash value signals a problem in the supply chain or production line.

Microbiological Stability

The amount and type of minerals in a food, known as the water activity, can influence its susceptibility to microbial growth. Ash content provides an indirect measure that helps in assessing a product's shelf life and stability.

Checking for Adulteration

An unusually high ash value can be a red flag for contamination or intentional adulteration. For example, spices could be adulterated with sand or ground-up materials to increase weight, which would drastically and illegally increase the ash content.

This makes ash analysis a simple but effective first-pass screening tool for food fraud and safety.

Understanding the Limitations

It's a Total, Not a Specific, Measure

The primary limitation of ash analysis is that it provides a total or crude value. It tells you the total amount of minerals but does not differentiate between them.

It cannot tell you how much of the ash is beneficial calcium versus how much is sodium from added salt. For that, more advanced techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) are required.

High Temperatures Can Cause Losses

The high temperatures used in ashing can cause certain volatile minerals, like chlorides and nitrates, to be lost. This can lead to a slight underestimation of the true total mineral content.

The method must be carefully controlled and standardized to ensure results are repeatable and comparable.

Interpretation Requires Context

An ash value is meaningless in isolation. A value of "2% ash" is only useful when compared against a known standard or specification for that specific food product.

It is a comparative tool used to track consistency over time and to ensure a product falls within its expected range.

Making the Right Choice for Your Goal

Ash analysis is a foundational technique with different implications depending on your objective.

- If your primary focus is regulatory compliance and labeling: Use ash analysis as the official measure for total mineral content required for proximate analysis and nutrition facts.

- If your primary focus is quality control: Establish a baseline ash content for your raw materials and finished products to immediately detect deviations, ingredient substitutions, or contamination.

- If your primary focus is product development: Use ash content to understand how new ingredients or formulation changes impact the final product's mineral profile, which directly affects taste, texture, and stability.

Ultimately, this simple test provides a powerful and cost-effective snapshot of a food's quality, nutritional value, and authenticity.

Summary Table:

| Purpose of Ash Analysis | Key Benefit |

|---|---|

| Nutritional Labeling | Provides the total mineral content for accurate nutrition facts panels. |

| Quality Control | Verifies ingredient purity and detects deviations in product consistency. |

| Adulteration Detection | Flags potential contamination or food fraud (e.g., sand in spices). |

| Product Development | Helps assess how formulation changes affect mineral profile and stability. |

Need precise and reliable ash analysis for your food products? KINTEK specializes in high-quality lab equipment and consumables for accurate food testing. Our solutions help you ensure nutritional compliance, maintain product quality, and safeguard your brand. Contact our experts today to find the perfect analytical tool for your laboratory's needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why refractory materials are used in furnaces? Ensure Safety, Efficiency, and Process Purity

- How are samples typically prepared and measured using the diffuse reflection method? Optimize Your Lab's IR Spectroscopy

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- What are the conditions for a muffle furnace? Ensure Safety, Performance, and Longevity