The fundamental difference between a muffle furnace and other furnaces lies in its method of heating. A muffle furnace uses indirect heating, isolating the material being treated from the heat source and any combustion byproducts, whereas many other furnaces heat the material directly. This design is specifically engineered to prevent contamination.

While many furnaces can achieve high temperatures, the decision to use a muffle furnace is driven by one primary need: ensuring the absolute purity of the sample by protecting it from any external influence during the heating process.

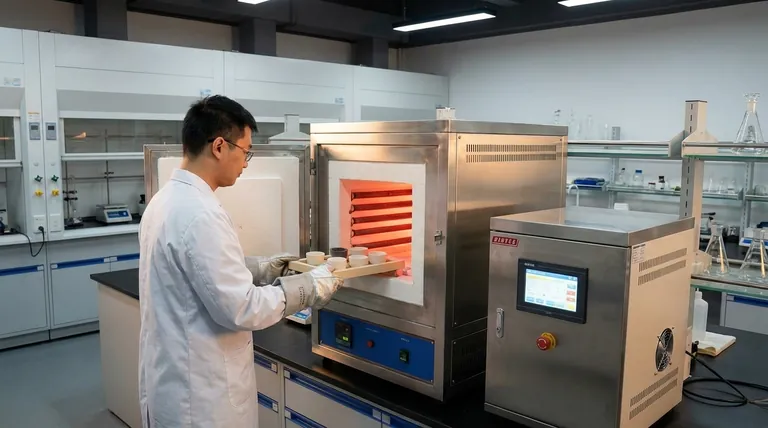

The Defining Principle: Indirect Heating

The core concept of a muffle furnace is creating a highly controlled, inert environment. This is achieved by separating the sample from the heating mechanism itself.

What is a "Muffle"?

A "muffle" is an insulated, enclosed chamber that contains the object to be heated. In modern electric furnaces, the heating coils or elements are positioned outside this chamber.

The chamber walls heat up and then radiate that energy inward, heating the sample uniformly without any direct contact with the heating elements. This entire insulated cabinet effectively acts as a muffle.

Preventing Contamination

The primary purpose of this design is to prevent contamination. In fuel-fired furnaces, byproducts of combustion like gases and soot can alter the chemical composition of a sample.

Even in electric furnaces, direct contact with a heating element could contaminate a sensitive material. The muffle acts as a physical barrier, ensuring the sample is only exposed to heat.

How Heat is Transferred

A muffle furnace operates on the principles of radiation and convection.

The electric heating elements heat the refractory material of the inner chamber walls. These superheated walls then radiate thermal energy evenly onto the sample inside.

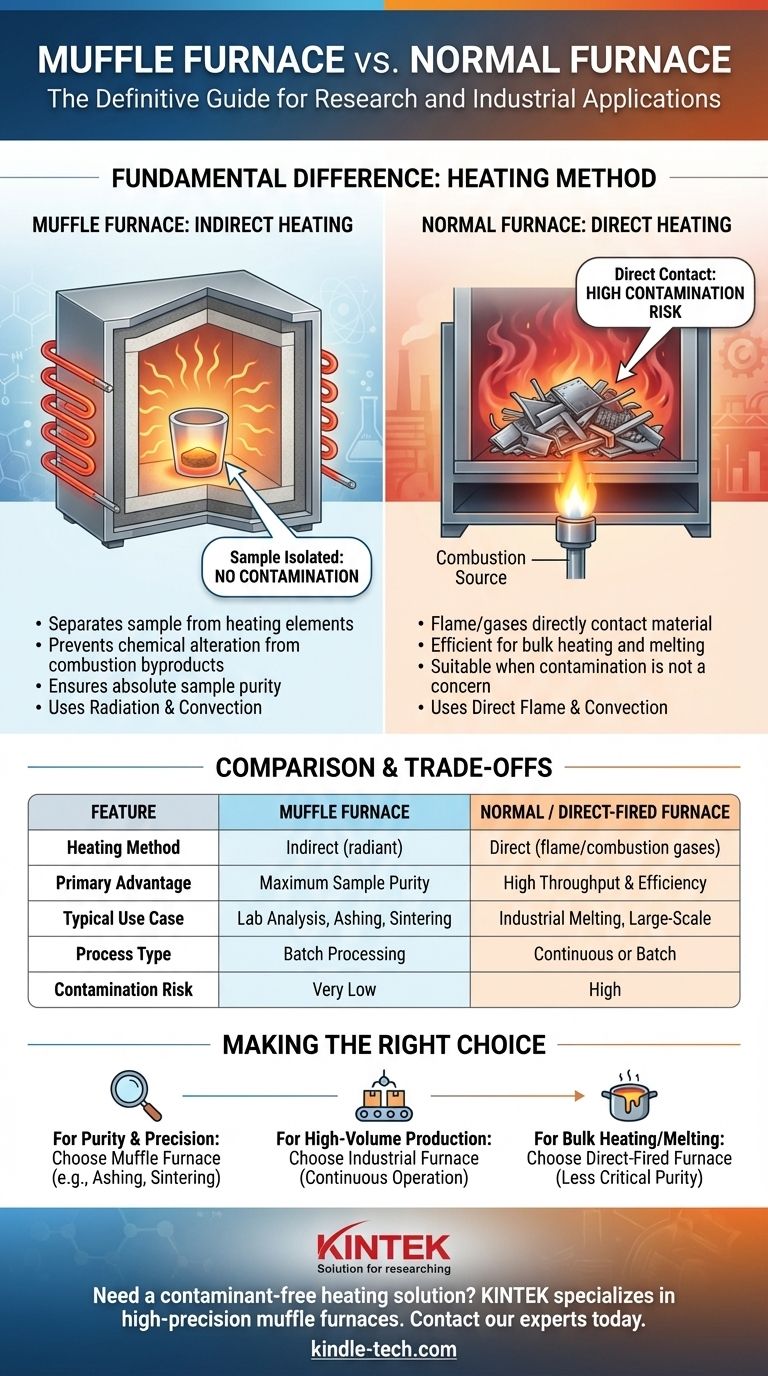

Muffle Furnace vs. Other Furnace Types

Understanding the muffle furnace is clearest when comparing it to furnaces designed for different goals, such as scale or direct heat application.

Comparison with Direct-Fired Furnaces

In a direct-fired or reverberatory furnace, the flame and hot gases from combustion come into direct contact with the material.

This is an efficient way to transfer heat for processes like melting large quantities of metal, where potential contamination from the fuel source is not a primary concern.

Scale of Operation: Lab vs. Industrial

Muffle furnaces are typically designed for batch processing on a smaller scale, making them ideal for laboratory work, material testing, or small-scale specialized production.

Industrial furnaces are often built for continuous operation, processing a constant flow of material on a massive scale. They are complex systems with integrated preheaters, exhaust systems, and combustion devices.

Precision and Control

Laboratory muffle furnaces are engineered for exceptionally precise temperature control. They use sophisticated PID controllers and thermocouples to maintain a stable, uniform temperature, which is critical for scientific analysis and delicate heat-treatment processes.

Understanding the Trade-offs

Choosing a muffle furnace involves weighing its unique advantages against its operational limitations.

Advantage: Purity and Precision

The single greatest advantage is the contaminant-free heating environment it provides. This is non-negotiable for applications like ashing biological samples, elemental analysis, or sintering advanced ceramics where purity is paramount.

Advantage: Energy Efficiency

For their size, muffle furnaces are highly energy-efficient. Their self-contained, heavily insulated design minimizes heat loss, allowing for rapid heating and cooling cycles in a compact cabinet.

Limitation: Batch Processing

The design of a muffle furnace makes it inherently a batch-process tool. It is not suitable for any application that requires a continuous flow of material through the heating chamber.

Limitation: Throughput

While a muffle furnace can heat up quickly, its capacity is limited. This makes it impractical for high-volume manufacturing where the goal is to process as much material as possible in the shortest amount of time.

Making the Right Choice for Your Application

Selecting the correct furnace is a direct function of your process requirements.

- If your primary focus is sample purity and avoiding contamination: A muffle furnace is the correct choice for processes like ashing, sintering, or delicate materials analysis.

- If your primary focus is high-volume, continuous production: A large-scale industrial furnace designed for continuous operation is the only viable solution.

- If your primary focus is simply melting or bulk heating without concern for contamination: A less complex and more cost-effective direct-fired furnace may be a better fit.

Ultimately, your choice depends on whether your process prioritizes the integrity of the final product or the scale of its production.

Summary Table:

| Feature | Muffle Furnace | Normal / Direct-Fired Furnace |

|---|---|---|

| Heating Method | Indirect (radiant) | Direct (flame/combustion gases) |

| Primary Advantage | Maximum sample purity, no contamination | High throughput, efficient for bulk heating |

| Typical Use Case | Laboratory analysis, ashing, sintering, small-batch R&D | Industrial melting, large-scale production |

| Process Type | Batch processing | Continuous or batch |

| Contamination Risk | Very Low | High (from fuel/byproducts) |

Need a contaminant-free heating solution for your lab? KINTEK specializes in high-precision muffle furnaces designed for applications where sample integrity is critical, such as ashing, sintering, and materials testing. Our energy-efficient, compact designs ensure precise temperature control and uniform heating for reliable results. Contact our experts today to find the perfect furnace for your laboratory's unique needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the role of muffle furnace in fluid mechanics? A Key Tool for Material Preparation

- What is the principle of muffle furnace in laboratory? Master Precise High-Temp Heating

- How to cool a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- What are the parts of a muffle furnace? Uncover the Core Components for Precision Heating

- What is a muffle furnace used in determination of? Precise Ash Content and Material Composition