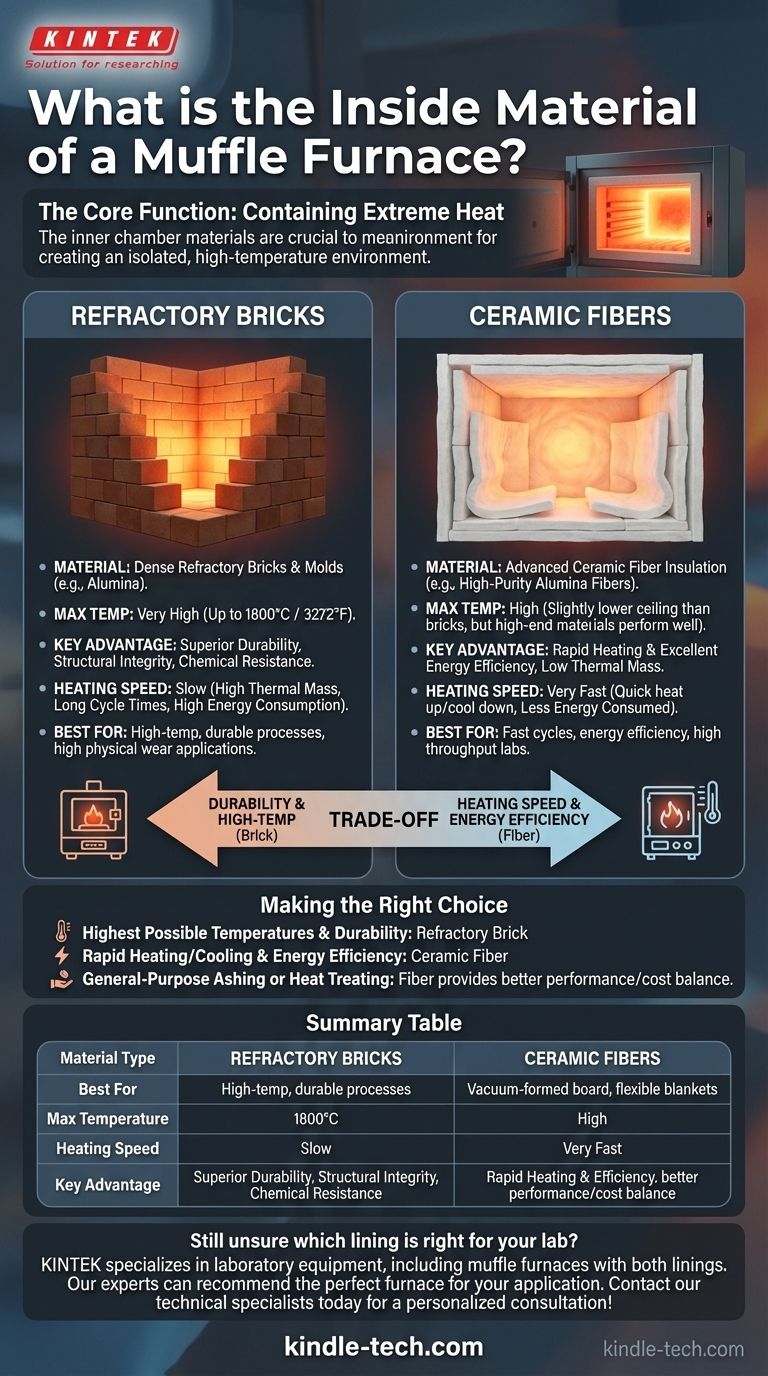

In short, the inside of a muffle furnace is constructed from high-temperature refractory materials. These are primarily specialized ceramics, most commonly in the form of dense refractory bricks or lightweight ceramic fibers. The specific material chosen depends on the furnace's intended maximum temperature, heating speed, and durability requirements.

The choice of a muffle furnace's internal material is a critical engineering decision. It's a direct trade-off between the rugged, high-temperature capabilities of dense refractory bricks and the rapid heating speed and energy efficiency of modern ceramic fibers.

The Core Function: Containing Extreme Heat

A muffle furnace's primary purpose is to create an isolated, high-temperature environment. The materials lining the inner chamber are therefore the most critical components for achieving and maintaining these conditions safely and efficiently.

The Role of Refractory Materials

The term refractory describes a class of materials that are chemically and physically stable at very high temperatures. They provide thermal insulation and resist corrosion, making them essential for furnace construction.

Any material used inside the furnace chamber for applications above 200°C must be a suitable refractory material to avoid damage or melting.

Common Material 1: Refractory Bricks & Molds

Traditionally, and in many heavy-duty furnaces today, the inner chamber is built from dense refractory firebricks or pre-fabricated ceramic molds.

These materials, often containing alumina, are known for their exceptional durability and ability to reach very high working temperatures, sometimes up to 1800°C (3272°F). Their density provides excellent structural integrity and resistance to physical wear.

Common Material 2: Ceramic Fibers

Modern furnaces frequently use advanced ceramic fiber insulation for the inner lining. This material can be made from high-purity alumina fibers that are vacuum-formed into rigid boards or flexible blankets.

Ceramic fiber offers excellent thermal insulation with very low thermal mass. This means the furnace heats up and cools down much faster, consuming less energy.

Understanding the Trade-offs: Brick vs. Fiber

The decision to use refractory brick or ceramic fiber is not arbitrary. Each comes with a distinct set of advantages and disadvantages that make them suitable for different applications.

Durability and Maximum Temperature

Dense refractory brick chambers generally offer superior durability and a higher maximum operating temperature. Their solid construction withstands mechanical stress and a more aggressive chemical environment.

While robust, ceramic fiber can be more susceptible to physical damage and may have a slightly lower service ceiling than the most robust brick designs. However, high-end fiber materials still perform exceptionally well.

Heating Speed and Energy Efficiency

Ceramic fiber is the clear winner for speed and efficiency. Its low thermal mass means very little energy is wasted heating the furnace itself, allowing it to reach the setpoint temperature rapidly. This is ideal for labs with high throughput and frequent temperature cycles.

Refractory brick, with its high thermal mass, stores a significant amount of heat. This causes it to heat up and cool down much more slowly, resulting in longer cycle times and higher energy consumption per cycle.

Contamination and Cleanliness

High-quality ceramic fiber linings are designed to be stable and not shed particles. However, in applications where microscopic contamination is a critical concern, a solid ceramic muffle or brick-lined chamber may be preferred for its perfectly smooth, non-shedding surface.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your process requirements.

- If your primary focus is reaching the highest possible temperatures or maximum durability: A furnace lined with dense refractory bricks is likely the best choice.

- If your primary focus is rapid heating/cooling cycles and energy efficiency: A furnace with a ceramic fiber lining is the superior option for most laboratory work.

- If your primary focus is general-purpose ashing or heat treating: Either material will work, but a fiber-lined furnace often provides a better balance of performance and operational cost.

Ultimately, understanding the internal materials empowers you to choose a furnace that is a precise tool for your specific scientific or industrial goal.

Summary Table:

| Material Type | Best For | Max Temperature | Heating Speed | Key Advantage |

|---|---|---|---|---|

| Refractory Brick | High-temp, durable processes | Very High (Up to 1800°C) | Slow | Superior durability & high-temp capability |

| Ceramic Fiber | Fast cycles, energy efficiency | High | Very Fast | Rapid heating & excellent energy efficiency |

Still unsure which muffle furnace lining is right for your lab's unique needs?

The experts at KINTEK are here to help. We specialize in providing laboratory equipment and consumables, including a wide range of muffle furnaces with both refractory brick and ceramic fiber linings. Our team can analyze your specific application—whether it's high-temperature processing, rapid heat treatment, or general ashing—and recommend the perfect furnace to maximize your efficiency, accuracy, and ROI.

Let us help you make the right choice. Contact our technical specialists today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What temperature is needed for metal casting? Achieve Perfect Casts with the Right Superheat

- What is the most common form of heat treatment? Mastering Annealing, Hardening, and Tempering

- What heat can a muffle furnace produce? Achieve Precise High Temperatures Up to 1800°C

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance