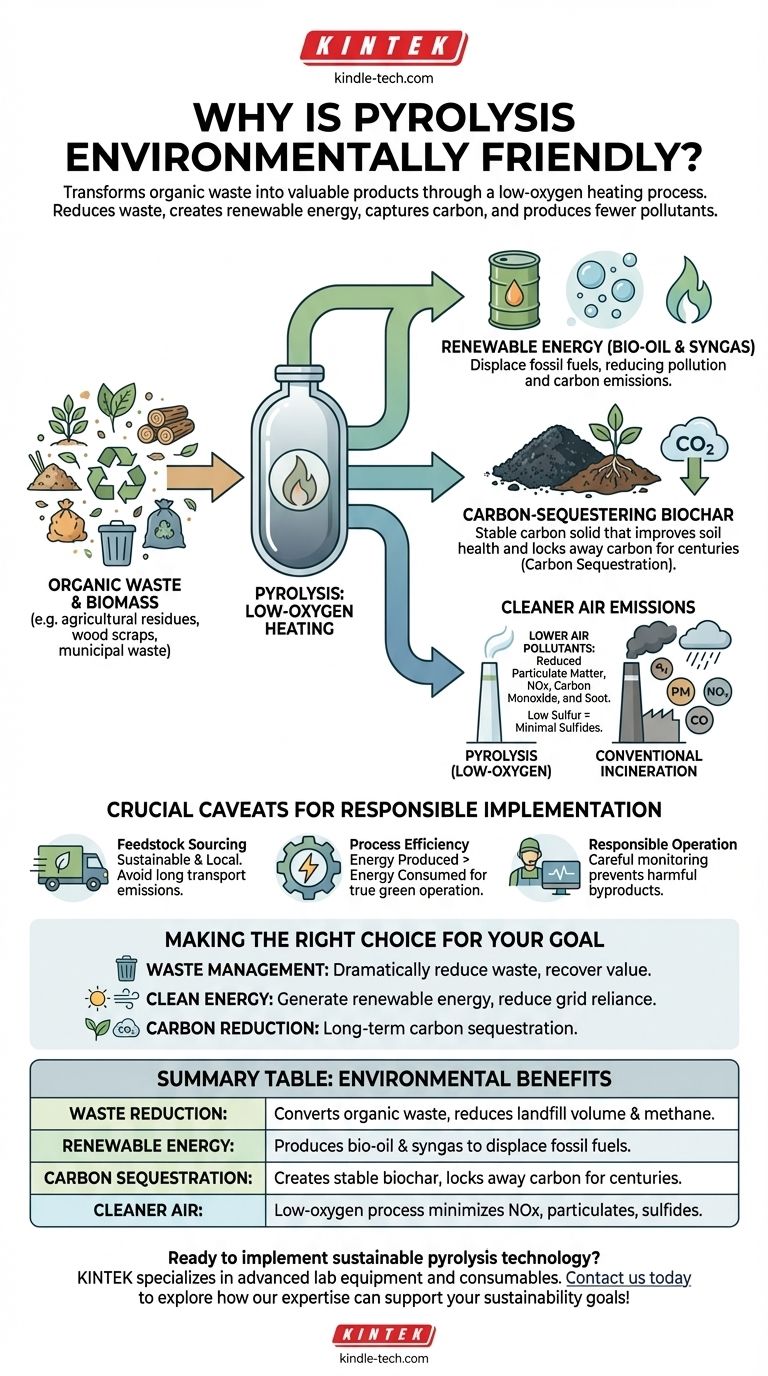

At its core, pyrolysis is considered environmentally friendly because it transforms organic waste materials into valuable products through a low-oxygen heating process. This method simultaneously reduces waste volume, creates renewable energy sources, captures carbon in a stable form, and produces significantly fewer air pollutants compared to conventional incineration or the burning of fossil fuels.

The primary environmental advantage of pyrolysis is its dual function: it is both a waste management solution and a clean energy production technology. It addresses the problem of organic waste disposal while concurrently displacing the need for fossil fuels and their associated pollution.

A Two-Fold Advantage: Reducing Waste and Creating Resources

Pyrolysis excels by fundamentally changing our perspective on waste. Instead of being a liability to be disposed of, organic material becomes a valuable feedstock for producing energy and other useful products.

Transforming Waste into Value

Pyrolysis provides a highly effective method for processing diverse waste streams. This includes agricultural residues, wood scraps, and even municipal solid waste, diverting them from landfills where they would otherwise decompose and release methane, a potent greenhouse gas.

Creating Renewable Energy

The process generates bio-oil and syngas, which can be used as clean-burning fuels. By converting biomass into energy, pyrolysis reduces our dependence on fossil fuels, directly cutting down on the pollution and carbon emissions associated with their extraction and combustion.

Producing Carbon-Sequestering Biochar

One of the most significant outputs of pyrolysis is biochar, a stable, carbon-rich solid. When added to soil, biochar doesn't just improve soil health; it effectively locks away carbon for hundreds or thousands of years. This process of carbon sequestration actively removes carbon dioxide from the atmospheric cycle.

A Clearer Path to Cleaner Air

Compared to direct burning (incineration), the controlled, low-oxygen environment of pyrolysis results in a much cleaner emissions profile.

Reducing Harmful Emissions

The anoxic (low-oxygen) process used in pyrolysis significantly limits the formation of air pollutants. This leads to lower concentrations of particulate matter, nitrogen oxides (NOx), carbon monoxide, and soot, which are common byproducts of conventional combustion.

Leveraging Low-Sulfur Feedstocks

Biomass feedstocks like wood chips and straw naturally contain very little sulfur. As a result, the pyrolysis process emits minimal sulfides, a primary contributor to acid rain, ensuring emissions remain well within national control standards.

Understanding the Crucial Caveats

While pyrolysis offers substantial benefits, its environmental friendliness is not automatic. Responsible implementation is essential to realizing its full potential.

The Importance of Feedstock Sourcing

The overall carbon footprint of a pyrolysis operation depends heavily on its feedstock. Transporting biomass over long distances can offset some of the emissions benefits. Sustainable sourcing from local waste streams is critical for maximizing its positive impact.

Process Efficiency and Energy Input

Pyrolysis requires an initial energy input to heat the feedstock. A truly "green" operation must be highly efficient, ensuring that the energy produced is significantly greater than the energy consumed to run the system.

Responsible Operation is Key

The environmental benefits hinge on the process being carried out correctly. Improperly managed systems or incomplete pyrolysis can still produce harmful byproducts. Careful monitoring and control are non-negotiable for ensuring a clean and effective operation.

Making the Right Choice for Your Goal

To determine if pyrolysis is the right technology, align its strengths with your primary objective.

- If your primary focus is waste management: Pyrolysis offers a powerful method to dramatically reduce waste volume while recovering value, turning a disposal liability into a resource asset.

- If your primary focus is clean energy production: It provides a pathway to generate renewable energy from local, decentralized sources, reducing reliance on the fossil fuel grid.

- If your primary focus is carbon reduction: The production and application of biochar offer a direct and stable method for long-term carbon sequestration, actively removing CO2 from the atmosphere.

By understanding both its powerful benefits and its operational requirements, you can effectively evaluate pyrolysis as a key tool for a more sustainable system.

Summary Table:

| Environmental Benefit | How Pyrolysis Achieves It |

|---|---|

| Waste Reduction | Converts organic waste into valuable products, reducing landfill volume and methane emissions. |

| Renewable Energy | Produces bio-oil and syngas to displace fossil fuels and lower carbon emissions. |

| Carbon Sequestration | Creates stable biochar that locks away carbon in soil for centuries. |

| Cleaner Air | Low-oxygen process minimizes pollutants like NOx, particulate matter, and sulfides. |

Ready to implement sustainable pyrolysis technology in your operations? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're focused on waste management, clean energy production, or carbon reduction, our solutions help you optimize processes for maximum environmental benefit. Contact us today to explore how our expertise can support your sustainability goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time