Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

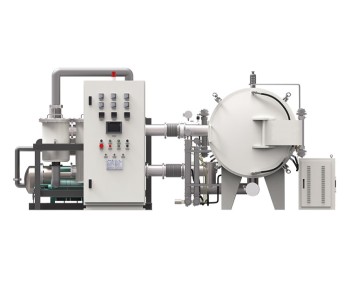

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Sealed Jaw Crusher High Efficiency Environmental Protection Safe and Reliable

Item Number : KT-EPB

Customizable Fuel Cell Stack Components for Diverse Applications

Item Number : FCS

FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

Item Number : FSE

Automatic Laboratory Heat Press Machine

Item Number : PZAH

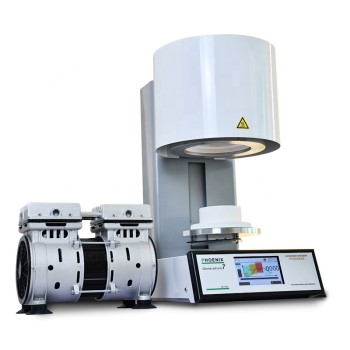

Touchscreen Automatic Vacuum Heat Press

Item Number : PPZC

Variable Speed Peristaltic Pump

Item Number : KT-VSP

Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

Item Number : KT-VP

Powerful Plastic Crusher Machine

Item Number : KT-HX

Circulating Water Vacuum Pump for Laboratory and Industrial Use

Item Number : KT-VWP

High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

Item Number : KT-VHE

High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

Item Number : COA-7

Laboratory Test Sieves and Sieving Machines

Item Number : KT-RCZ

High Performance Laboratory Stirrers for Diverse Applications

Item Number : KTL-9

Shaking Incubators for Diverse Laboratory Applications

Item Number : KTL-8

1200℃ Muffle Furnace Oven for Laboratory

Item Number : KT-12M

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Item Number : KT-CG03

Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

Item Number : KT-CG02

Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

Item Number : KTL-7

Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

Item Number : KTL-6

Small Cryogenic Grinder Cryomill Cryogrinder with Liquid Nitrogen for Laboratory Use

Item Number : KT-DC31

Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

Item Number : TPM-04

Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

Item Number : TPM-02

Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

Item Number : PTFE-01

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Engineering of Absence: Unlocking Material Purity Through Vacuum Furnaces

Discover how vacuum furnaces prevent oxidation and ensure material integrity by heating in a near-airless environment. Explore the science of pure heat treatment.

The Architecture of Accuracy: Why the Electrolytic Cell Lid is Your Most Critical Interface

There is no universal standard for electrolytic cell lids, though Φ6.2mm and Φ3.2mm are common. Learn why precise aperture configuration is vital for data integrity.

Why Your Compacted Parts Fail: The Hidden Flaw Your Sintering Furnace Can't Fix

Struggling with inconsistent powder-pressed parts? The real flaw isn't your furnace. Learn how Cold Isostatic Pressing ensures flawless results.

The Fragile Intersection: Mastering the Side-Window Optical Electrolytic Cell

Spectroelectrochemistry combines chemical, electrical, and optical hazards in a delicate vessel. Here is how to master the safety and precision of this complex system.

The Architecture of Precision: Why the Invisible Details Define Electrochemical Success

Master the art of pre-use inspection for electrolytic cells. From physical integrity to electrode purity, learn why the invisible details dictate experimental safety.

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Thermal Ceiling: Pushing 2200°C in Vacuum Environments

Discover how specialized vacuum furnaces achieve 2200°C+ through advanced graphite and tungsten elements. A deep dive into thermal engineering and material limits.

The Glass Heart of the Experiment: Precision Through Systematic Care

Routine maintenance of double-layer electrolytic cells isn't just cleaning—it's calibration. Discover the systematic protocol for reproducible electrochemical data.

The Art of Nothing: Why Critical Engineering Demands Vacuum Brazing

Discover how vacuum furnace brazing eliminates oxidation for superior joint integrity, the physics of vapor pressure, and why material selection dictates the process.

The Thermodynamic Paradox: Balancing Precision and Safety in Electrolytic Cells

Master temperature control in double-layer water-bath electrolytic cells. Understand material limitations, prevent thermal damage, and ensure data integrity.

The Quiet Physics of Purity: Mastering Heat in a Vacuum

Vacuum furnaces don't just heat; they fundamentally alter physics by replacing convection with radiation. Explore how removing air unlocks material perfection.

The Hidden Reason Your Powder Metallurgy Parts Keep Failing (And It’s Not Your Furnace)

Tired of cracked sintered parts? The problem isn't your furnace. Learn the real root cause—uneven density—and how Cold Isostatic Pressing fixes it.

The Thermodynamics of Consistency: Mastering the Invisible Variable in Electrolysis

Discover why temperature is the silent killer of electrochemical precision. Learn how double-layer electrolytic cells engineer thermal stability for repeatable results.

The Silent Half of the Experiment: The Ritual of Cell Preservation

Post-experiment care isn't just cleanup; it's calibration for the future. Learn the precise protocols for maintaining super-sealed electrolytic cells.

The Geometry of Cleanliness: Why Surface Integrity Defines Electrochemical Success

Master the art of electrolytic cell maintenance. Discover how a tiered cleaning protocol prevents contamination and ensures experimental reproducibility.

The Art of Nothingness: Precision and Purity in Vacuum Heat Treatment

Discover the engineering logic behind vacuum furnaces. Learn how eliminating air prevents oxidation, ensures purity, and enables advanced metallurgy.

The Art of the Empty Vessel: Preparing Quartz Electrolytic Cells for Absolute Precision

Reliable electrochemical data isn't just about the reaction; it's about the setup. Discover the systematic approach to preparing quartz cells for perfect fidelity.

The Art of the Finish: Why the Most Critical Moment Happens After the Data is Collected

The experiment isn't over when the data is saved. Learn the psychological and technical art of shutting down and cleaning optical electrolytic cells.

The Thermodynamics of Patience: Preventing Electrolytic Cell Overload

Overloading an electrolytic cell isn't just an error; it's a systemic failure. Learn the physics of safety, the risks of excess energy, and how to maintain control.

The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells

Precision in electrochemistry isn't about guesswork; it's about hardware architecture. Learn how the three-electrode system isolates variables for true control.