Material Section

Before embarking on your creative journey, let's familiarize ourselves with the available assets.

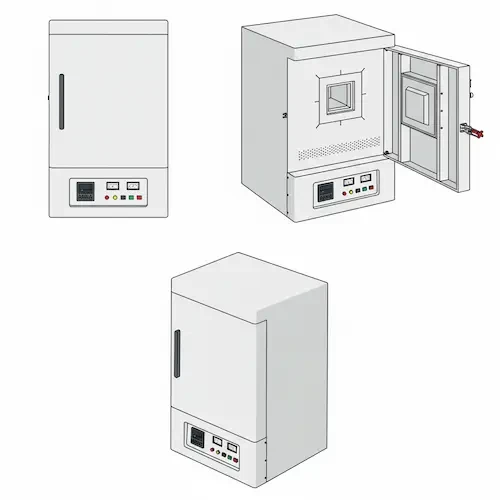

1. Muffle Furnace Three-View Drawings

Here are multi-angle views of the muffle furnace KT-M12, including front, left, and right side views in both open and closed states. These detailed perspectives will offer rich referential detail for your image editing.

2. Generated Image Assets

In addition to the muffle furnace itself, we provide some generated image assets showcasing its internal structure and design philosophy, including:

3. Common Tool Link

-

Nano banana Link: https://aistudio.google.com/u/0/prompts/new_chat

4. Generated Prompt Keywords

-

Transform the provided photograph (Image 1) of the industrial furnace into a clean, isometric line art illustration style, similar to the aesthetic of Image 2, Image 4, Image 5, or Image 6. The final image should feature minimalistic, flat gray and white colors for the casing, with clear, sharp black outlines defining all components and edges. Emphasize the technical drawing appearance, showing the control panel details, door hinge, and handle with precision. Remove the original white photographic background and replace it with a pure, flat white background. The overall impression should be that of a professional engineering diagram or a technical product rendering, without any photographic realism. The image should be in an isometric perspective, maintaining the original subject's orientation but transforming its rendering style.

-

Transform the provided photograph of an industrial furnace into a clean, isometric line illustration style. The final image should feature a minimalist off-white palette, with all components and edges outlined in sharp black. Emphasize the aesthetic of technical drawings, accurately depicting control panel details, door handles, and any visible hinges. Crucially, retain the object's original frontal perspective and remove the original white photographic background, replacing it with a pristine, flat white background. The overall effect should resemble a professional engineering schematic or technical product rendering, completely abandoning photographic realism. The illustration should capture the essence of an isometric view while keeping the subject oriented toward the viewer.

Practical Exercise: Generating Scientific Illustrations from Scratch

Step 1: Submit Official Documentation to Gemini, Input:

"Please carefully review Gemini's official documentation, especially the prompt examples for image editing. The document provides detailed guidance and examples; integrate this content thoroughly."

Step 2: Interact with Gemini to Generate Customized Prompts

Assuming your requirement is to convert a muffle furnace image with a white background into a scientific illustration style, you can instruct Gemini as follows: "You are now my nanobanana prompt expert. Based on the official prompt documentation and my personal image editing needs, generate precise nano banana English editing prompts."

Gemini will provide prompts in various styles according to your requirements, for example:

Step 3: Copy the Prompt and Open a New Chat, Select the Nano Banana Model.

-

Enter your chosen prompt.

![Step 3 of the procedure]()

-

Wait a few minutes, and Gemini will generate the scientific illustration that meets your requirements.

![Step 4 of the procedure]()

Optimization and Adjustment

If the initially generated image does not fully meet your expectations, do not worry. You can return to the Gemini conversation interface to further refine and adjust your prompts. Through more precise descriptions and instructions, you can gradually guide Gemini to achieve your ideal illustration effect.

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Related Articles

- Why Your Furnace Experiments Fail: The Hidden Mismatch in Your Lab

- The Architecture of Emptiness: Mastering Material Selection in Vacuum Furnaces

- Box Furnace vs. Muffle Furnace: Are You Using the Wrong Tool for the Job?

- Comprehensive Guide to Muffle Furnaces: Applications, Types, and Maintenance

- Why Your High-Temperature Experiments Fail: It's Not the Heat, It's the Furnace