You've spent weeks developing a novel material. The final step is a complex, multi-stage heating process in the lab furnace. You program the thermal profile perfectly, but the result is a fractured, useless sample. The experiment failed, not because of your science, but because the "stable" temperature inside your furnace was anything but. For researchers and engineers working with high-temperature applications, this scenario is an all-too-common source of wasted time, budget, and potential.

The Real Challenge: A Single Degree of Error

High-temperature processes like material sintering, sample ashing, and metal annealing are foundational to countless scientific and industrial advancements. The goal is simple in theory: apply a precise amount of heat for a specific duration to controllably transform a material.

The execution, however, is fraught with a persistent challenge: thermal instability. This isn't about whether a furnace can get hot; it's about whether it can follow a complex temperature path with absolute fidelity. The "dragon" that plagues labs and production lines has three heads:

- Temperature Overshoot: The furnace gets hotter than the setpoint, potentially damaging the sample or altering its microstructure unpredictably.

- Thermal Lag: The furnace fails to ramp up temperature quickly enough, ruining time-sensitive reactions or processes.

- Temperature Drift: During a critical hold phase (or "soak"), the temperature fluctuates, introducing a major variable that makes experimental results impossible to reproduce.

For decades, these issues were accepted as a necessary evil. A process that worked on Monday would fail on Tuesday for no apparent reason, leading to inconsistent product quality in manufacturing and non-reproducible data in research—a critical flaw when seeking publication or validating a discovery.

The Breakthrough: From Approximation to Execution

The victory over this challenge isn't a single discovery but a fundamental shift in capability: the ability to create a thermal environment where the programmed heating curve and the actual temperature curve inside the furnace are virtually identical.

Imagine executing a 50-segment heating profile for crystal growth, where each ramp and soak is timed to the minute and accurate to within a single degree. In this scenario:

- What is done: A complex, multi-stage thermal cycle is performed.

- How it's done: By leveraging a system that can anticipate and correct for thermal fluctuations in real-time.

- What is found: The material—be it a ceramic composite, a purified chemical, or an annealed metal alloy—emerges with the exact desired properties, every single time.

This isn't about just heating; it's about precise thermal choreography. This reliability transforms the furnace from a simple "hot box" into a true scientific instrument, enabling researchers to isolate variables and trust their results.

The Enabler: Engineering That Eliminates Thermal Chaos

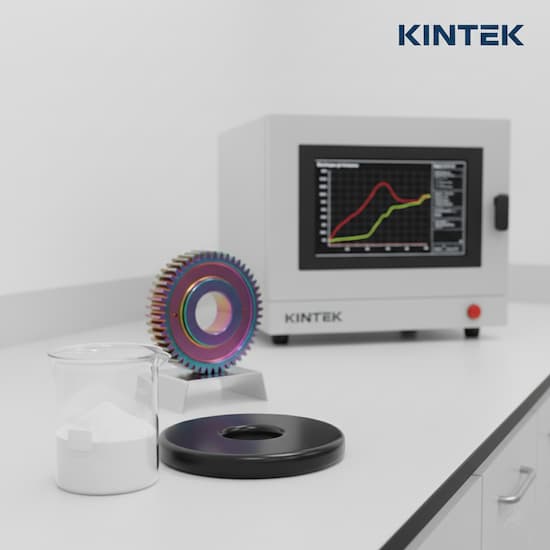

This level of control is made possible by a tool engineered specifically to tame the dragon of thermal instability: the KINTEK Box (Muffle) Furnace. The breakthrough in repeatability is a direct result of solving specific engineering problems.

Conquering Drift with Intelligent Control

The core of the problem lies in crude temperature regulation. The KINTEK furnace solves this using a microcomputer PID (Proportional-Integral-Derivative) intelligent controller. This isn't a simple thermostat; it's a predictive algorithm that constantly monitors temperature trends. It preemptively reduces power as it approaches a setpoint to prevent overshoot and makes micro-adjustments to hold stability within ±1°C. This directly eliminates the temperature drift that invalidates sensitive experiments.

Accelerating Results with Superior Insulation

Traditional furnaces lined with heavy refractory bricks suffer from immense thermal inertia, leading to slow heat-up times and wasted energy. The KINTEK furnace utilizes a chamber made of high-purity ceramic fiber. This advanced material provides superior insulation while being significantly lighter, allowing for:

- 30% faster heating speeds, reducing the time from a cold start to a ready state.

- 20-25% lower energy consumption, directly impacting operational costs.

For a busy lab, this means more experimental cycles can be completed in a single day, dramatically increasing throughput.

A New Horizon: From Lab Discovery to Industrial Production

Mastering thermal processing at the bench scale unlocks vast potential. When a materials scientist can reliably produce a novel compound, or a QC manager can consistently verify sample purity, it builds the foundation for larger success.

This capability, powered by KINTEK's precision technology, has a direct commercial impact across industries:

- New Drug Development: High-temperature purification of pharmaceutical intermediates can be performed with higher yields and fewer impurities.

- Advanced Materials: The development of next-generation ceramics, alloys, and composites accelerates when sintering and annealing processes are perfectly repeatable.

- Quality Control: In industries from food to metallurgy, determining ash content or testing material stability becomes a reliable, standardized process, not a source of inconsistency.

Because this core technology scales from small laboratory box furnaces to large industrial muffle furnaces, the process you perfect during R&D can be confidently deployed for full-scale production, ensuring a seamless transition from breakthrough to market-ready product.

The right thermal processing equipment does more than just heat things up; it eliminates variables, accelerates discovery, and guarantees quality. If you're facing challenges with material synthesis, quality control, or scaling your research, the limitation may not be your process, but your tools. Let's discuss how the right precision furnace can solve your specific application needs.

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

Related Articles

- Why Your High-Temperature Experiments Fail: It's Not the Heat, It's the Furnace

- Box Furnace vs. Muffle Furnace: Are You Using the Wrong Tool for the Job?

- Why Your Ashing Tests Fail: The Hidden Difference Between Muffle and Ashing Furnaces

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Why Your High-Temperature Experiments Fail: The Furnace Flaw Most Labs Overlook