Introduction to Vacuum Furnaces

Operating Principles

A vacuum furnace operates as a specialized form of industrial heating equipment, designed to carry out heating processes within an environment that approximates a vacuum. This furnace type employs a sophisticated vacuum system to significantly lower the pressure within its chamber, often to levels far below one standard atmospheric pressure. This deliberate reduction in pressure effectively creates a vacuum environment, which is essential for the unique heat treatment processes it facilitates.

The vacuum environment within these furnaces is crucial for several reasons. Firstly, it prevents the oxidation and decarburization of materials, which are common issues in conventional heating processes. By eliminating the presence of oxygen, vacuum furnaces can maintain the integrity and quality of the materials being processed. Additionally, the vacuum setting enhances heating efficiency and precision, allowing for more controlled and uniform temperature distribution.

Moreover, the absence of gas molecules in a vacuum means that heat transfer primarily occurs through radiation. This mode of heat transfer, which involves the emission of electromagnetic waves, does not require a medium to propagate, making it highly efficient in a vacuum setting. This radiant heat transfer mechanism is fundamental to the operation of vacuum furnaces, enabling them to achieve and maintain high temperatures with remarkable accuracy and consistency.

In summary, the operating principles of a vacuum furnace revolve around its ability to create and sustain a near-vacuum environment, which not only protects materials from harmful atmospheric interactions but also optimizes the heat transfer process through radiation. This dual capability makes vacuum furnaces indispensable in various industrial applications requiring precise and high-temperature heat treatment.

Advantages of Vacuum Heat Treatment

Vacuum heat treatment offers a multitude of benefits that make it a superior choice over conventional methods. One of the most significant advantages is the prevention of oxidation and decarburization, which are common issues in traditional heat treatment processes. In a vacuum environment, the absence of air eliminates these risks, ensuring that the material retains its integrity and desired properties.

Moreover, vacuum heat treatment significantly enhances the control over heating and cooling parameters. This precision allows manufacturers to tailor the process to specific materials, resulting in improved hardness, strength, and other mechanical properties. The uniform heating and cooling achieved in a vacuum environment also minimize the risk of distortions and warping, which are particularly beneficial for components with complex geometries.

| Advantage | Description |

|---|---|

| Preventing Oxidation and Decarburization | Eliminates the risk of surface defects caused by exposure to air. |

| Enhanced Control Over Parameters | Allows for precise adjustments to heating and cooling cycles, optimizing material properties. |

| Uniform Heating and Cooling | Reduces the likelihood of distortions and warping in complex components. |

Additionally, vacuum heat treatment can improve surface hardness and wear resistance. By subjecting the material to controlled heating and cooling cycles in a vacuum, the crystalline structure is optimized, leading to a harder and more durable surface. This is particularly advantageous in applications where longevity and resistance to wear are critical.

The controlled environment of vacuum heat treatment also allows for the precise management of the gas atmosphere within the chamber. This capability is essential for preventing contamination and ensuring that the material undergoes the desired transformation without any undesirable reactions. The consistent and repeatable results produced by this method provide a high level of predictability, which is crucial for industries with stringent quality assurance standards.

Finally, vacuum heat treatment is often more energy-efficient compared to traditional methods. The absence of a combustion process and the reduced need for post-treatment cleaning contribute to a more environmentally friendly approach, aligning with current sustainability trends in manufacturing.

Heat Transfer in Vacuum Furnaces

Radiant Heat Transfer

In a vacuum, heat transfer occurs primarily through radiation. Unlike conduction and convection, which rely on the presence of gas molecules to facilitate heat exchange, radiation operates independently of any medium. This unique characteristic makes it the dominant mode of heat transfer in vacuum environments.

Radiant heat transfer involves the emission of electromagnetic waves, primarily in the infrared spectrum, from a hot source to a cooler object. These waves carry energy that can be absorbed by the cooler object, thereby raising its temperature. The absence of gas molecules in a vacuum eliminates the possibility of conduction and convection, leaving radiation as the sole method for heat transfer.

To illustrate, consider the operation of a vacuum furnace. In such a furnace, the heating elements emit radiant energy that directly impacts the materials being processed. This direct interaction ensures efficient heat transfer without the losses associated with conduction or convection in atmospheric conditions. The result is a controlled and precise heating process that is crucial for applications requiring high-temperature treatments without oxidation or contamination.

In summary, radiant heat transfer is the cornerstone of thermal processes in vacuum environments, offering a reliable and efficient means of heating materials without the need for a physical medium.

Temperature Range and Applications

Temperature Capabilities

The temperature range of vacuum furnaces is exceptionally broad, enabling the attainment of extremely high temperatures. The maximum temperature achievable in a vacuum furnace can span from just a few hundred degrees Celsius to several thousand degrees Celsius, depending on the design and the heating element employed. This wide temperature spectrum is crucial for accommodating various industrial processes that require precise temperature control.

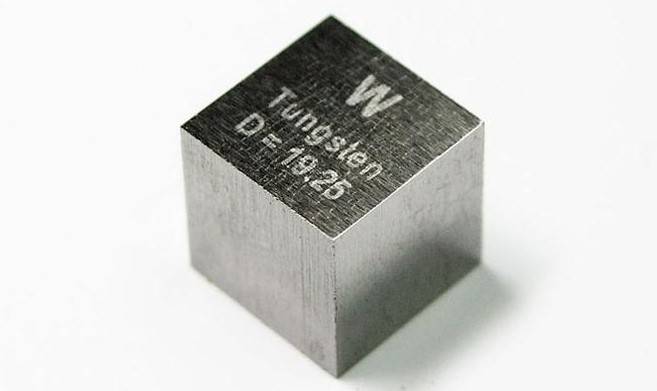

For instance, certain advanced materials processing applications necessitate temperatures exceeding 2000°C, which can only be reliably achieved in a vacuum environment. The ability to reach such high temperatures is facilitated by the use of specialized heating elements like graphite, tungsten, and molybdenum, which are capable of withstanding and efficiently conducting heat at these extreme levels.

| Heating Element | Typical Temperature Range | Application Examples |

|---|---|---|

| Graphite | 1000°C - 3000°C | Metal heat treatment, vacuum brazing |

| Tungsten | 1500°C - 3000°C | High-temperature sintering, vacuum melting |

| Molybdenum | 1000°C - 2000°C | Semiconductor manufacturing, ceramic processing |

The flexibility in temperature capabilities of vacuum furnaces makes them indispensable in industries such as aerospace, automotive, and electronics, where the integrity and performance of materials are paramount. By offering a controlled environment devoid of atmospheric contaminants, vacuum furnaces ensure that the materials processed remain free from oxidation and other detrimental effects, thereby enhancing their quality and reliability.

Main Applications

Vacuum furnaces, owing to their unique operating principles and environments, are indispensable in various high-precision industrial processes. These furnaces are particularly renowned for their role in metal heat treatment, where they prevent oxidation and decarburization, ensuring the integrity and quality of the final product. Additionally, they are extensively used in vacuum brazing, a technique that joins metals without the need for filler materials, thereby maintaining the purity of the metals involved.

In the realm of vacuum sintering, these furnaces play a crucial role in consolidating powdered materials into a solid mass, a process essential in the production of advanced ceramics and metals. Vacuum melting is another critical application, where these furnaces are used to melt metals under vacuum conditions, ensuring the removal of impurities and achieving precise alloy compositions.

Moreover, vacuum furnaces are integral in vacuum coating processes, which apply thin layers of materials to surfaces, enhancing their properties such as hardness, corrosion resistance, and aesthetic appeal. In semiconductor manufacturing, these furnaces are employed for the deposition and annealing of semiconductor materials, ensuring the production of high-quality electronic components.

The versatility of vacuum furnaces extends to ceramic and glass processing, where they are used for firing and annealing, ensuring the durability and aesthetic qualities of these materials. Lastly, they are invaluable in scientific research experiments, providing a controlled environment for high-temperature experiments and material studies.

| Application | Description |

|---|---|

| Metal Heat Treatment | Prevents oxidation and decarburization, ensuring material integrity. |

| Vacuum Brazing | Joins metals without filler materials, maintaining purity. |

| Vacuum Sintering | Consolidates powdered materials into solid masses. |

| Vacuum Melting | Melts metals under vacuum to remove impurities and achieve precise alloys. |

| Vacuum Coating | Applies thin layers to surfaces, enhancing properties like hardness and corrosion resistance. |

| Semiconductor Manufacturing | Used for deposition and annealing of semiconductor materials. |

| Ceramic and Glass Processing | Firing and annealing to ensure durability and aesthetic qualities. |

| Scientific Research | Provides controlled environments for high-temperature experiments. |

Carrier Materials and Refractory Properties

Importance of Carrier Materials

In a vacuum furnace, the carrier material that supports the heated material and the refractory properties of the furnace lining are critical components. These materials must endure extreme conditions, including high temperatures and the absence of atmospheric pressure or specific controlled atmospheres.

To function effectively, these materials must exhibit several key characteristics:

- Thermal Stability: They must maintain their structural integrity and chemical composition under prolonged exposure to high temperatures.

- Chemical Inertness: They should not react with the heated material or the furnace environment, ensuring the purity and integrity of the process.

- Mechanical Strength: They must be robust enough to withstand the mechanical stresses associated with handling and positioning the heated material, as well as the thermal cycling inherent in the furnace operation.

These properties are essential to ensure the reliable and efficient operation of the vacuum furnace, ultimately affecting the quality and consistency of the heat treatment process.

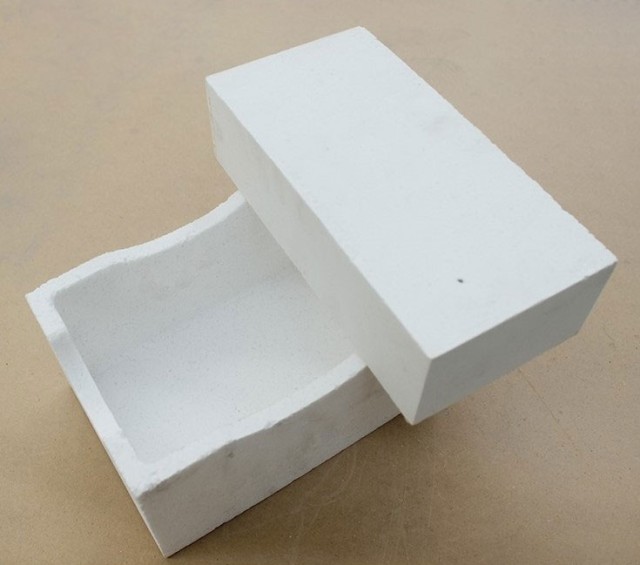

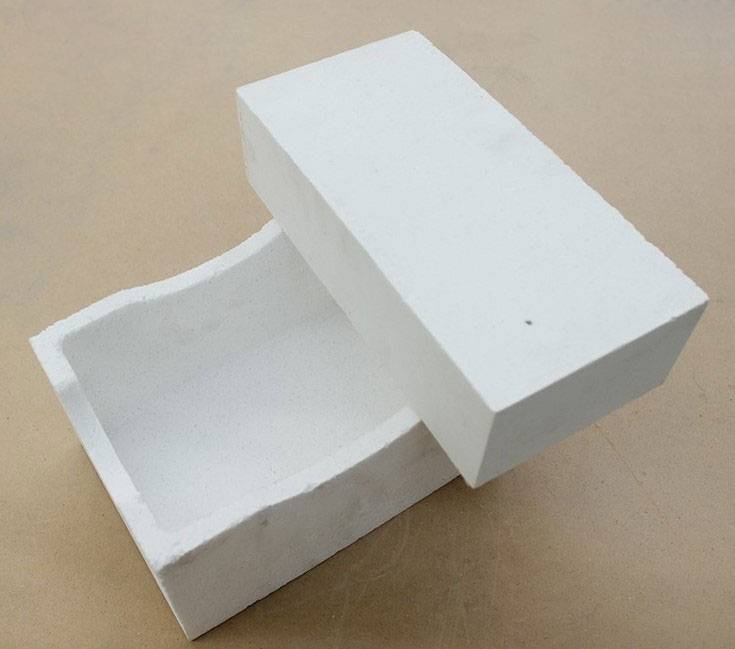

Common Materials Used

In vacuum furnaces, the selection of materials for heating elements, carriers, and structural components is crucial due to the extreme conditions they must endure. Graphite stands out as a primary choice due to its excellent thermal conductivity and ability to maintain structural integrity at high temperatures. It is often used for heating elements and as a carrier material, ensuring efficient heat transfer and stable operation.

Metals such as tungsten and molybdenum are also extensively used. These metals possess high melting points and excellent resistance to thermal degradation, making them ideal for heating elements. Their ability to withstand extreme temperatures without significant deformation or loss of functionality is particularly advantageous in vacuum environments.

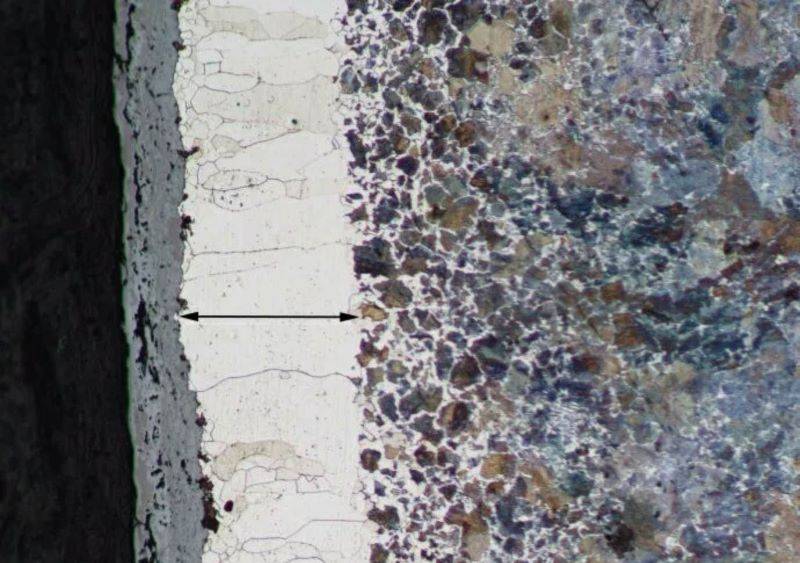

Ceramic materials like alumina (Al₂O₃) and zirconia (ZrO₂) are indispensable for structural components. Alumina offers exceptional thermal stability and chemical inertness, while zirconia adds superior mechanical strength and thermal shock resistance. These properties make ceramic materials ideal for use in the construction of furnace linings and other critical structural elements, ensuring durability and longevity under the demanding conditions of vacuum furnaces.

| Material Type | Common Examples | Key Properties | Applications |

|---|---|---|---|

| Graphite | Graphite rods, sheets | High thermal conductivity, structural stability | Heating elements, carriers |

| Metals | Tungsten, Molybdenum | High melting points, thermal resistance | Heating elements |

| Ceramics | Alumina, Zirconia | Thermal stability, chemical inertness, mechanical strength | Structural components, furnace linings |

The combination of these materials ensures that vacuum furnaces can operate efficiently and reliably, even under the most stringent conditions.

Recommended Refractory Materials

Based on Temperature Ranges

When selecting refractory materials for vacuum furnaces, it is crucial to consider the specific temperature requirements of the heating process. Each material has its unique thermal properties and optimal temperature ranges, making them suitable for different applications within the furnace.

For instance, alumina hollow ball bricks are ideal for environments requiring high thermal shock resistance and low thermal conductivity. These bricks are often used in furnaces where sudden temperature changes are common, ensuring minimal damage to the refractory lining.

In contrast, the MgO-ZrO2-SiO2 system chrome-free refractory is preferred for its excellent resistance to thermal stress and chemical corrosion. This material is particularly beneficial in high-temperature applications where maintaining the integrity of the refractory lining is essential.

Corundum mullite refractory bricks offer a balance between thermal conductivity and mechanical strength, making them suitable for a wide range of temperatures. They are commonly used in furnaces where both high-temperature stability and structural integrity are required.

For ultra-high temperature applications, graphite fibers or mats are the go-to materials. These offer exceptional thermal conductivity and can withstand temperatures exceeding 2000°C, making them indispensable in processes like vacuum melting and sintering.

Lastly, aluminosilicate sheets provide a cost-effective solution for moderate temperature ranges. Their ability to resist thermal shock and maintain structural stability at elevated temperatures makes them a practical choice for many industrial applications.

By understanding the specific temperature requirements and selecting the appropriate refractory material, operators can ensure the efficient and safe operation of their vacuum furnaces, ultimately enhancing the quality and consistency of their heating processes.

Conclusion

Choosing the Right Refractory Material

Selecting the appropriate refractory material for vacuum furnaces is a critical decision that hinges on several key factors. These include the specific temperature requirements of the furnace, the chemical environment it operates in, and a thorough cost-benefit analysis. By carefully considering these aspects, operators can ensure that their vacuum furnaces function smoothly at high temperatures, thereby extending the lifespan of the equipment, reducing operational costs, and enhancing the overall efficiency and quality of the heating process.

When choosing a refractory material, it is essential to evaluate its thermal properties. For instance, materials with low thermal conductivity are often preferred as they minimize heat loss and maintain a consistent temperature within the furnace. Additionally, resistance to corrosion and thermal shock are crucial, as these properties protect the refractory from degradation due to chemical reactions and sudden temperature changes.

The installation and maintenance of the refractory material also play significant roles in its selection. Ease of installation ensures that the refractory can be fitted correctly and efficiently, while ease of maintenance allows for regular inspections and repairs, ensuring the long-term performance of the furnace.

The suitability of a refractory lining is further influenced by operational conditions such as slag formation, operating temperature, and furnace capacity. For example, silica is typically used for acidic slags, magnesia for basic slags, and alumina for neutral slags. This tailored approach ensures that the refractory material is optimally matched to the furnace's specific needs, thereby enhancing its performance and durability.

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

Related Articles

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Materials Science with the Lab Vacuum Furnace